Activated carbon loaded iron-based low temperature SCR denitration catalyst, preparation method and application method thereof

A denitration catalyst, activated carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. requirements and other issues, to achieve the effect of simple components, good denitration effect, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

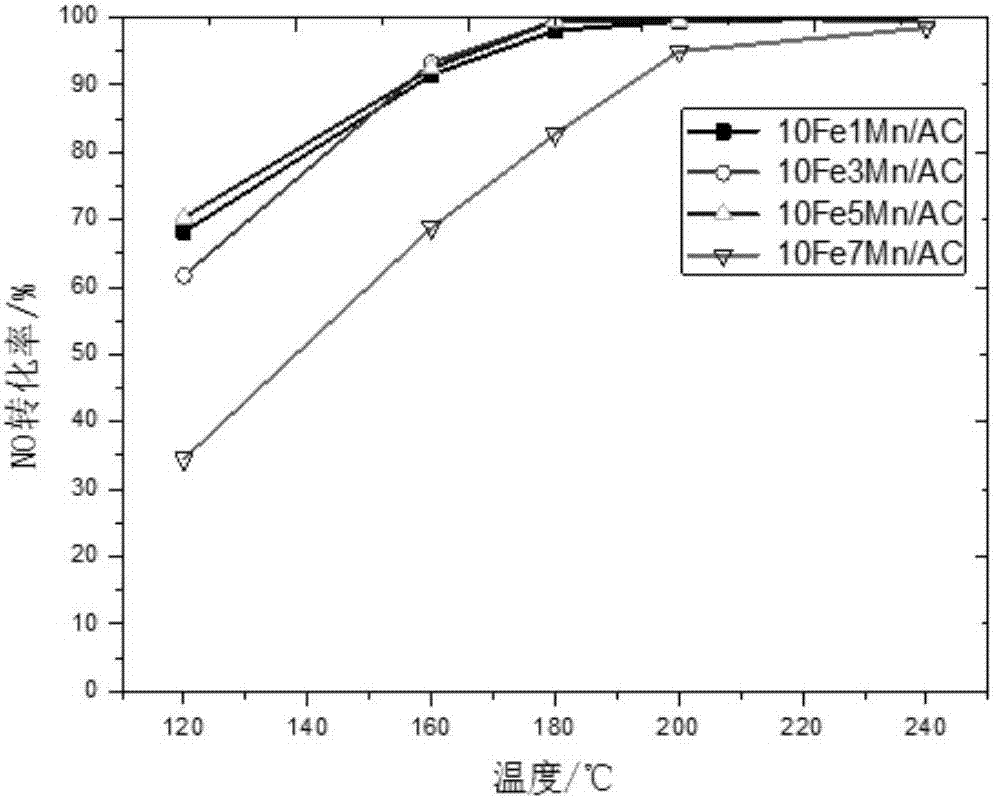

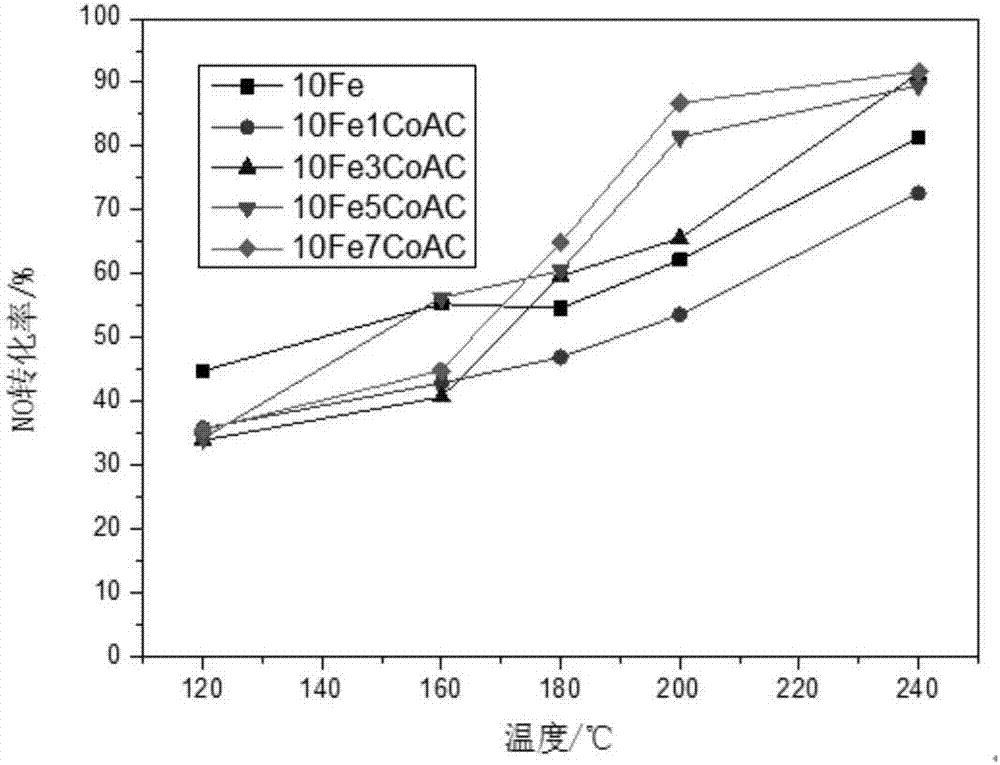

[0035] The preparation method of an activated carbon-loaded iron-based low-temperature SCR denitrification catalyst of the present invention uses ground activated carbon particles as a carrier, takes Fe oxides as the main active component, and adds a trace amount of Mn or Co to it as an active auxiliary agent , the active component is loaded on the carrier by impregnation method, and the catalyst is modified by roasting, which specifically includes the following steps:

[0036] (1) Dry the activated carbon carrier at 80-110°C for 3-5 hours, and then grind the dried activated carbon to 40-60 mesh to obtain small carrier particles;

[0037] (2) According to the mass ratio of each component in the catalyst, take ferric nitrate as the precursor of the active component respectively, take manganese nitrate or cobalt nitrate as the precursor of the active auxiliary agent, mix them uniformly and pour them into Add activated carbon carrier particles and deionized water, and stir evenly...

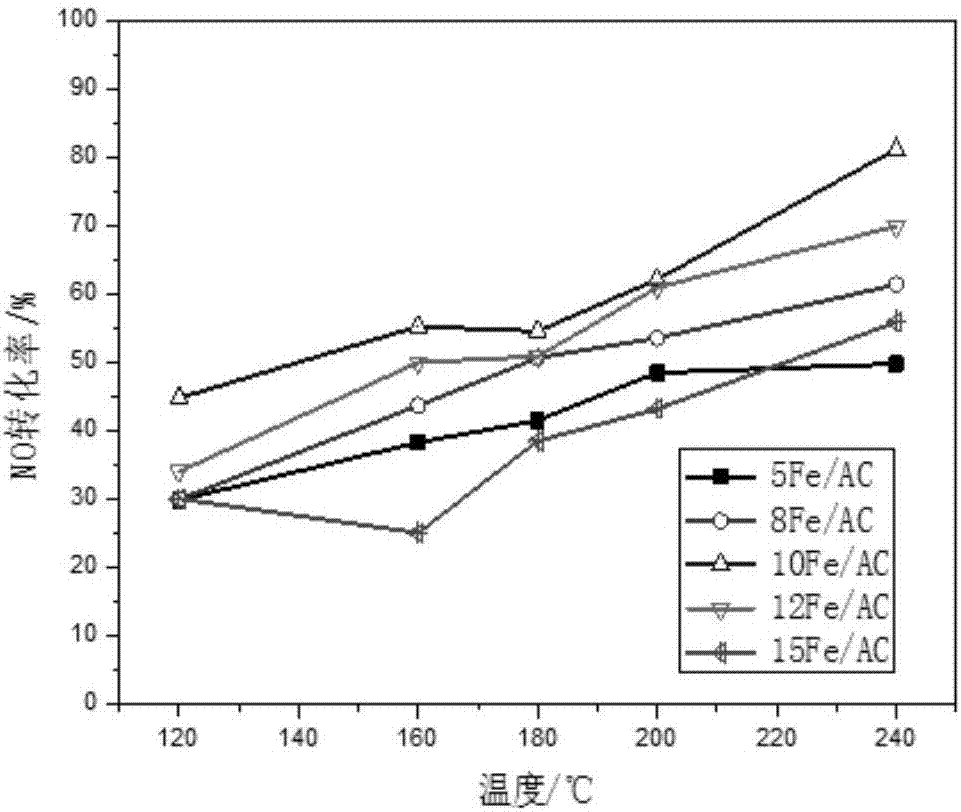

Embodiment 1

[0046] A method for preparing an activated carbon-supported iron-based low-temperature SCR denitration catalyst in this embodiment, the steps are: drying the activated carbon carrier at 80°C for 3 hours, and then grinding the dried activated carbon to 40 mesh (380 microns) to obtain small carrier particles, The activated carbon particles after grinding are used as the carrier, and the active components are loaded on the carrier by the impregnation method. First weigh a certain weight of activated carbon carrier, then calculate the mass of ferric nitrate solution that needs to be weighed according to the Fe load of 5% of the weight of the activated carbon carrier and the law of element conservation, then pour it into the beaker containing the activated carbon carrier, add After deionized water was fully stirred by a magnetic stirrer for 5 hours, it was placed in a blast drying oven at 80°C for 8 hours, and finally it was calcined in a closed air atmosphere at 350°C for 4 hours, ...

Embodiment 2

[0048] A preparation method of an activated carbon-supported iron-based low-temperature SCR denitration catalyst in this embodiment, the steps are: drying the activated carbon carrier at 110° C. for 5 hours, and then grinding the dried activated carbon to 60 mesh (250 microns) to obtain small carrier particles, Using the ground activated carbon particles as the carrier, the active components are loaded on the carrier by the impregnation method, first weigh a certain weight of the activated carbon carrier, and then calculate the Need to weigh the quality of the ferric nitrate solution, then pour it into a beaker loaded with activated carbon carrier, add deionized water, after fully stirring with a magnetic stirrer for 12 hours, place it in a blast drying oven at 90°C for 12 hours, and finally place it in a closed air atmosphere After calcining at 450°C for 6 hours, and then cooling with the furnace, the catalyst was obtained, marked as 10Fe / AC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com