High-temperature-resistant filtering material with ultra-clean filtering and low-temperature catalytic denitration functions, and preparation method thereof

A technology of low-temperature catalysis and filter materials, applied in chemical instruments and methods, physical/chemical process catalysts, filtration and separation, etc., can solve problems such as complex components of industrial smoke and dust, damage to filter materials, catalyst poisoning and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

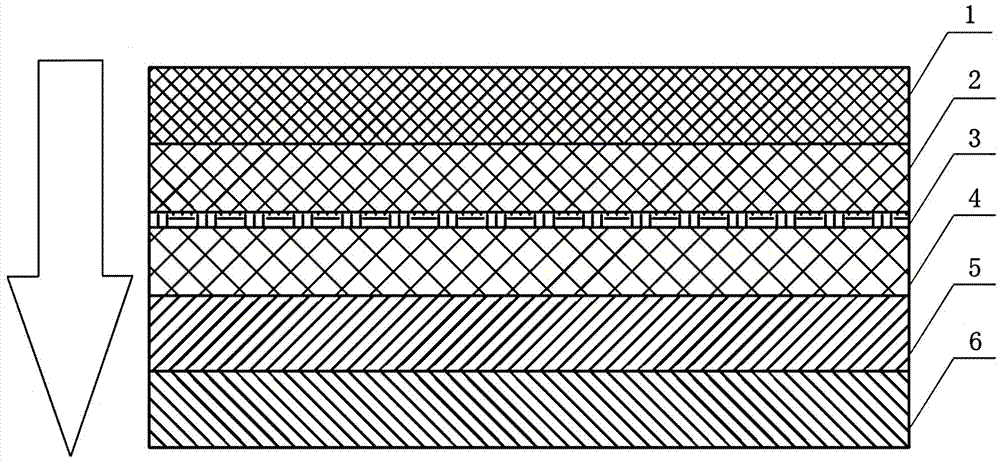

Image

Examples

Embodiment 1

[0035] This example prepares a high-temperature-resistant filter material with ultra-clean filtration and low-temperature catalytic denitrification. The specific steps are:

[0036] Pre-prepared catalyst coating solution, 60 parts of MnFe 2 o 4 / ACF, 40 parts of MnFe 2 o 4 / CNTs mixed catalyst, 20 parts of α, ω-dihydroxypolydimethylsiloxane with a dynamic viscosity (25°C) of 300mPa·s, 8 parts of phenyl silicone oil with a dynamic viscosity (25°C) of 100mPa·s Add it into a power mixer, stir at a speed of 600rpm for 20min, then add 2 parts of γ-glycidyl etheroxypropyl trimethoxysilane, stir for 10min at a pressure of -0.3MPa and a speed of 1000rpm, and then add 1 part of benzene Tributanone oxime silane and 0.1 part of tin dilaurate were stirred for 10 minutes at a pressure of -0.1 MPa and a rotation speed of 800 rpm to prepare a catalyst coating liquid.

[0037] Step 1. The sea-island type PPS superfine fiber with a fineness of 0.3 denier, the PPS superfine fiber with a fin...

Embodiment 2

[0045] This example prepares a high-temperature-resistant filter material with ultra-clean filtration and low-temperature catalytic denitrification. The specific steps are:

[0046] Pre-prepared catalyst coating solution, 30 parts of MnFe 2 o 4 / ACF, 40 parts of MnFe 2 o 4 / CNTs, 30 copies of Y 2 o 3 -MnOx / ZrO 2 Mixed catalyst, 30 parts of α, ω-dihydroxy polydimethylsiloxane with a dynamic viscosity (25°C) of 500 mPa·s, and 10 parts of phenyl silicone oil with a dynamic viscosity (25°C) of 100 mPa·s In the mixer, stir for 30min at a speed of 800rpm, then add 2 parts of γ-glycidyl etheroxypropyl trimethoxysilane, stir for 10min at a pressure of -0.3MPa, and a speed of 1000rpm, then add 1 part of phenyl trimethoxysilane in sequence Butanone oxime silane and 0.3 parts of tin dilaurate were stirred for 10 min at a pressure of -0.1 MPa and a rotation speed of 800 rpm to prepare a catalyst coating liquid.

[0047] Step 1. Split-type PEI ultra-fine fibers with a fineness of 0....

Embodiment 3

[0055] This example prepares a high-temperature-resistant filter material with ultra-clean filtration and low-temperature catalytic denitrification. The specific steps are:

[0056] Pre-prepared catalyst coating solution, 50 parts of MnFe 2 o 4 / ACF, 50 copies of Y 2 o 3 -MnOx / ZrO 2 Mixed catalyst, 20 parts of α, ω-dihydroxypolydimethylsiloxane with a dynamic viscosity (25°C) of 100 mPa·s, and 5 parts of phenyl silicone oil with a dynamic viscosity (25°C) of 500 mPa·s In the mixer, stir for 20min at a speed of 400rpm, then add 2 parts of γ-glycidyl etheroxypropyl trimethoxysilane, stir for 10min at a pressure of -0.3MPa, and a speed of 500rpm, then add 1 part of phenyl trimethoxysilane in sequence Butanone oxime silane and 0.2 parts of tin dilaurate were stirred for 10 min at a pressure of -0.1 MPa and a rotation speed of 800 rpm to prepare a catalyst coating liquid.

[0057] Step 1. The split-type P84 ultra-fine fiber with a fineness of 0.3 denier, the P84 ultra-fine fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com