Three-pool coordinated high-yield cultivation method for paddy field in south

A cultivation method and paddy field technology, which can be applied in the fields of rice cultivation, cultivation, plant cultivation, etc., can solve the problems of deteriorating tillage, insignificant effect, affecting the growth and development of rice and the potential for sustainable yield increase, etc. Economic benefits, the effect that is conducive to sustainable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]From November 2012 to October 2016, a field test was conducted in the paddy field of Huarong County, Hunan Province. The test site has a humid subtropical monsoon climate, with an average annual rainfall of 1200-1600mm, an annual average temperature of 16.7°C, and an active accumulated temperature of ≥10°C of 5 300- 5400℃, the annual sunshine hours are 1295.9h, and the frost-free period is 260-310d. The test soil is Zichao mud, the organic matter content of the basic soil is 25.21g / ㎏, the alkali-hydrolyzable nitrogen is 163.32mg / ㎏, the available phosphorus is 7.18mg / ㎏, the available potassium is 63.40mg / ㎏, and the pH value is 5.5. Three cultivation modes were set up in the experiment. Model 1, during the first production cycle from November 2012 to October 2013 and the fourth production cycle from November 2015 to October 2016, no-tillage in winter is used to plant green manure-early rice before throwing seedlings and plowing the straw deeply and pressing it back Field-...

Embodiment 2

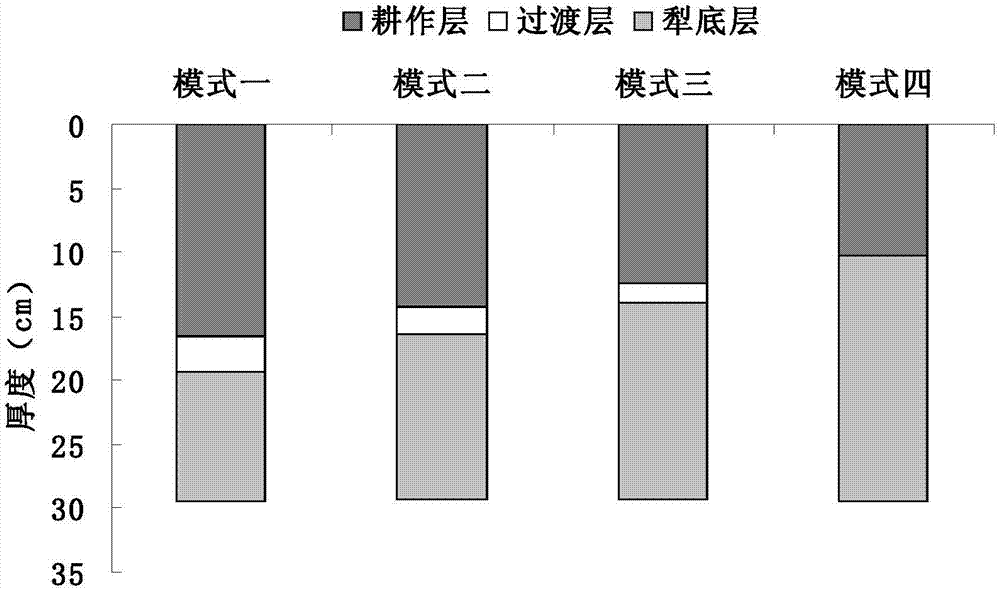

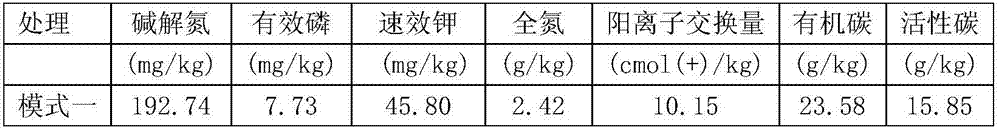

[0054] From March 2012 to November 2016, a field test was conducted in the paddy fields of Liling City, Hunan Province. The test site has a humid subtropical monsoon climate, with an average annual rainfall of 1429.7mm, an annual average temperature of 17.6°C, and an active accumulated temperature of ≥10°C of 5400-5600°C , the annual sunshine hours are 1325.6h, and the frost-free period is 270-320d. The test soil is tidal sand and mud. The organic matter content of the basic soil is 31.22g / kg, the alkali-hydrolyzed nitrogen is 160.31mg / kg, the available phosphorus is 6.58mg / kg, the available potassium is 34.06mg / kg, and the pH value is 4.86. The experimental planting mode is winter fallow-double cropping rice, and there are 4 cultivation modes in total. Model 1, 3-year cycle turning - no rotation tillage - rice straw returning to the field - wet irrigation, early and late rice turning in 2014, early and late rice no-tillage in 2015 and 2016; model 2, 4-year cycle turning - no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com