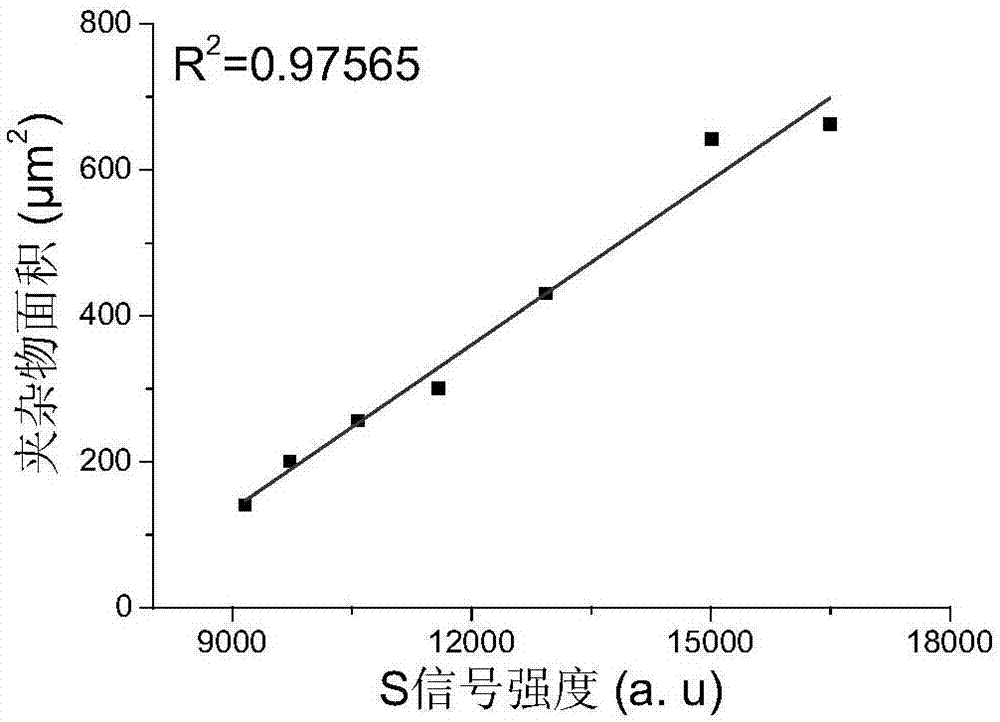

Analysis rating method for manganese sulfide inclusions in steel based on calibration curve

A calibration curve and inclusion technology, applied in the field of surface micro-area analysis in the field of materials science, can solve the problems of slow analysis speed, small observation area, cumbersome handling of steel material samples, etc., and achieve fast analysis speed and scan area range Large, simple sample preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

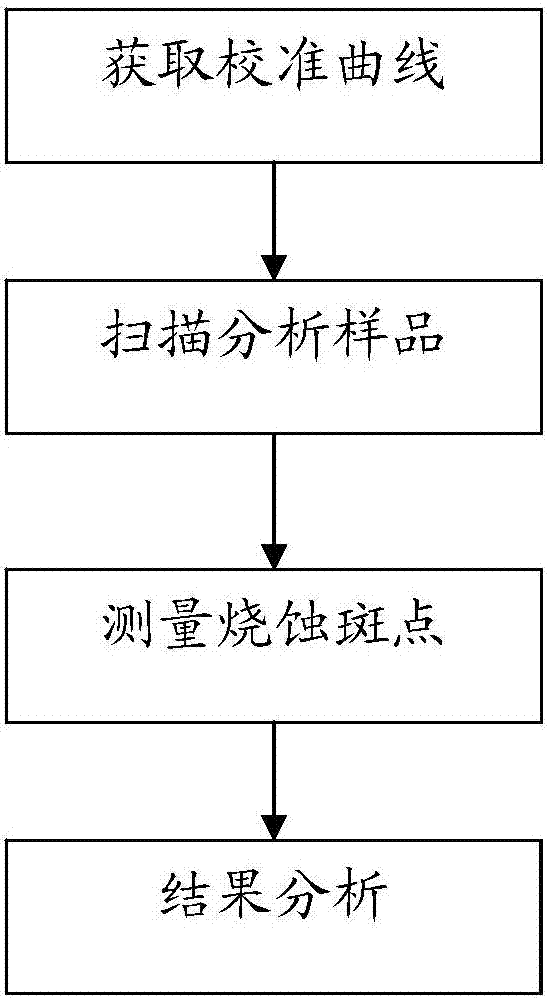

Method used

Image

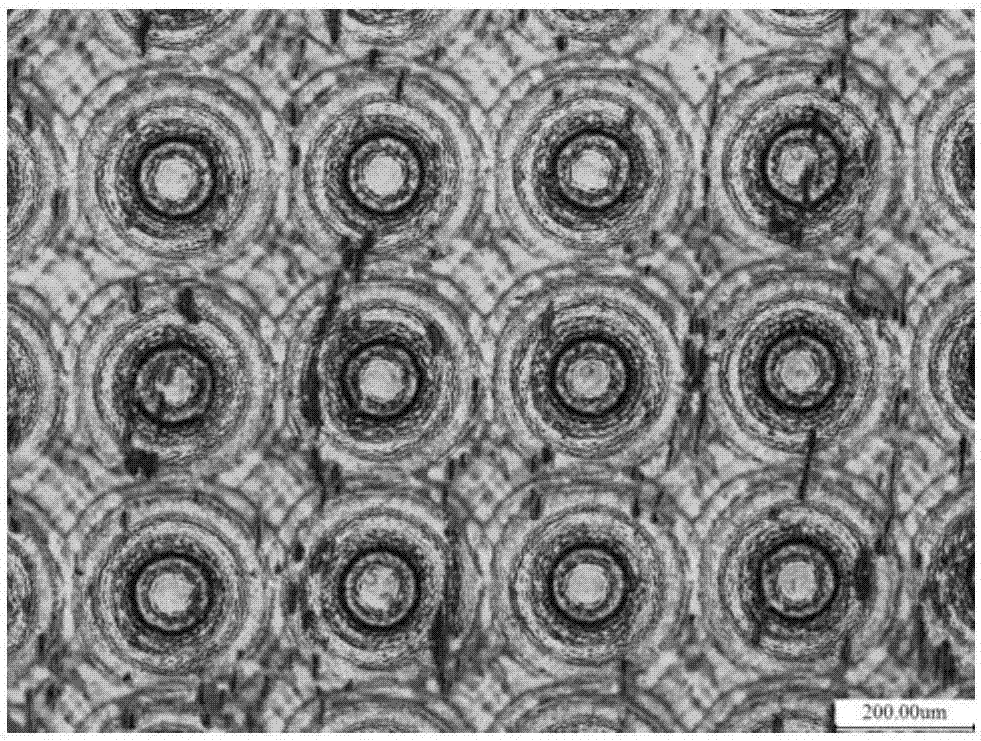

Examples

Embodiment

[0095] The method of the present invention and the M method in DIN50602 were used to grade 12 areas in a piece of free-cutting steel materials respectively. The comparison results are shown in Table 1. Here the relationship between the area and grade of manganese sulfide inclusions is A=2 n , Where A is the area of manganese sulfide inclusions and n is the number of grades. During the evaluation process, if the area of the manganese sulfide inclusions measured is between n and n+1, they are rounded down and rated as n.

[0096] Table 1 Comparison of rating results between the method of the present invention and the metallographic method

[0097]

[0098]

[0099] The results obtained by the analysis method of the present invention are in good agreement with the existing standard method of the comparative example, and can be used for the rating inspection of manganese sulfide inclusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com