Movable hydraulic power station

A hydraulic power station, hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo meter circuit, etc., can solve the inconvenience of emergency repair and rescue work, incompetence for long-term heavy load conditions, hydraulic equipment input Large flow and other problems, to ensure the continuous operation performance of heavy load, improve the convenience of handling and portability, and improve the efficiency of the hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

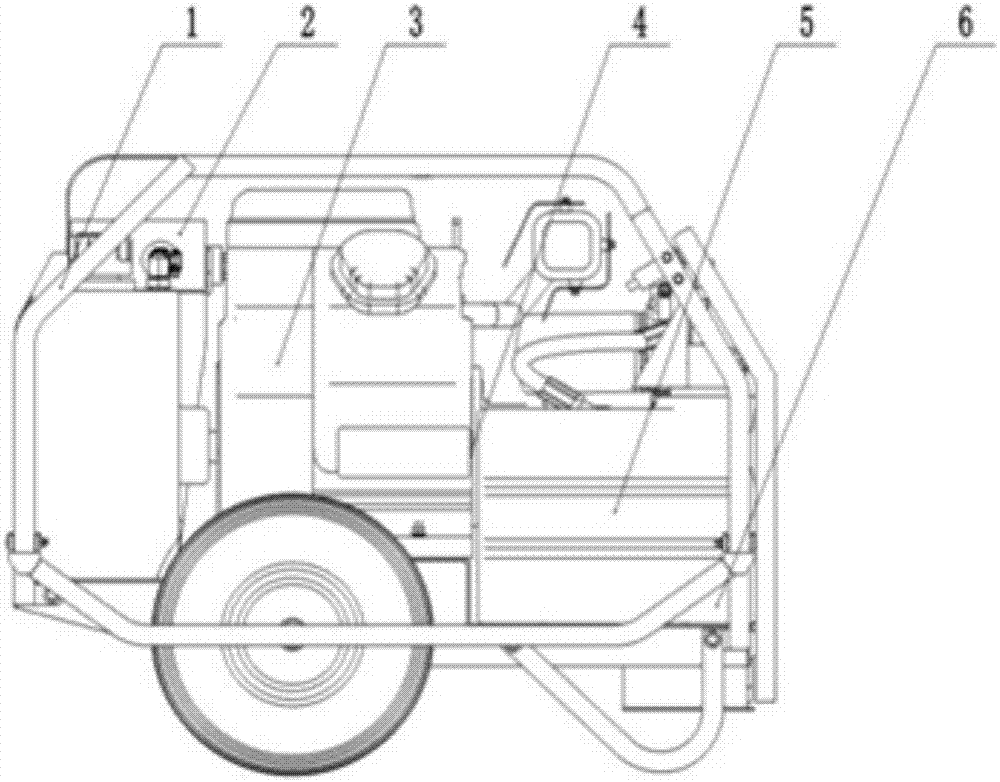

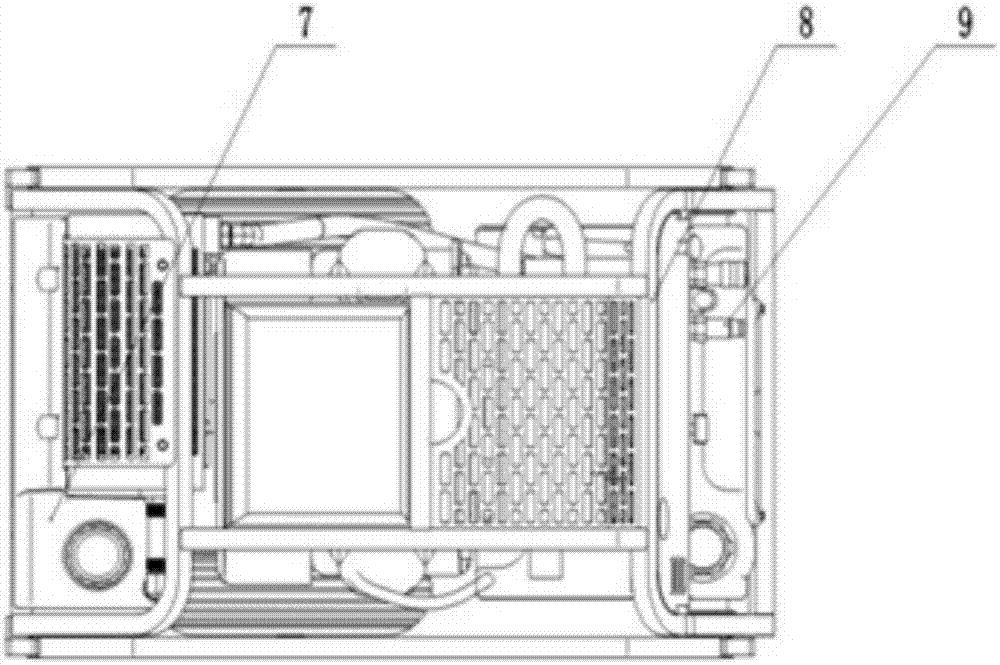

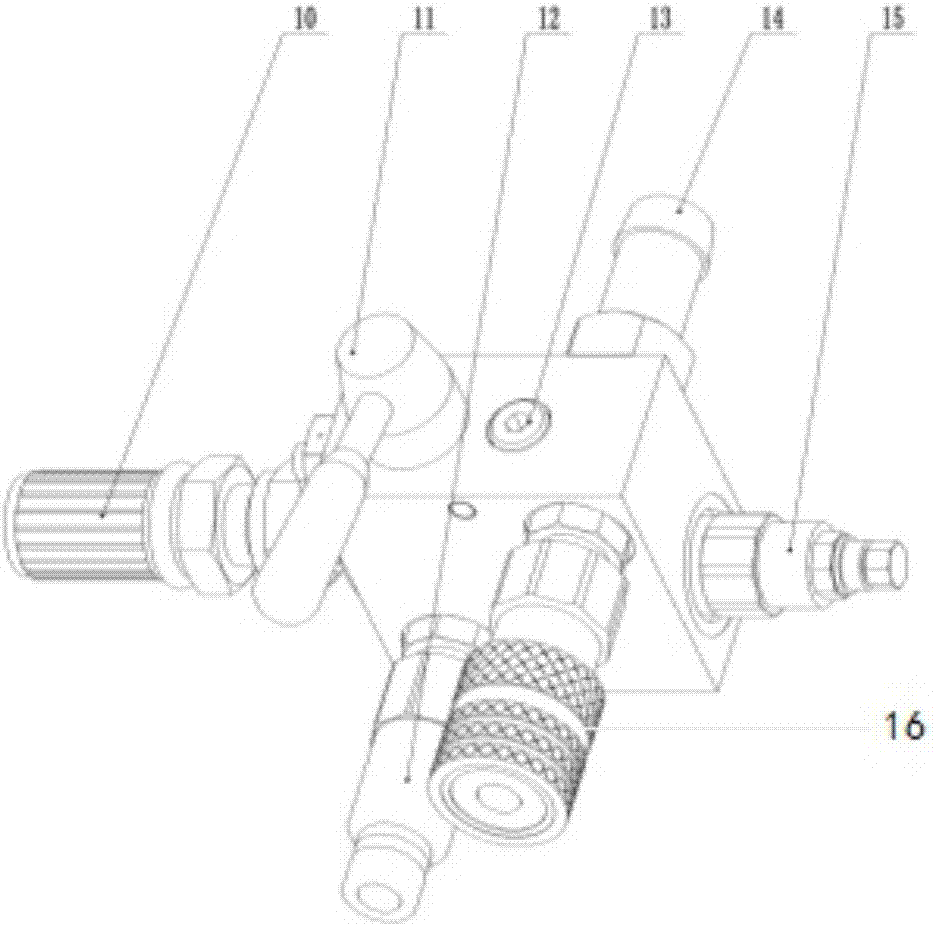

[0044] Such as figure 1 and figure 2 Shown, a kind of mobile hydraulic power station, described hydraulic power station comprises frame 1, gasoline engine 3, main pump 4, hydraulic oil tank 7, hydraulic integrated control valve 8, fuel tank and battery that provide fuel and power for engine; Frame 1 includes a frame and a bottom frame. The bottom frame is a steel structure to support the weight of the power system, fuel tank and hydraulic oil tank. The frame is made of aluminum alloy. The frame and the bottom frame are connected by bolts. The frame is made of aluminum alloy. The frame adopts steel and aluminum mixed structure.

[0045] An engine 3 is arranged in the middle part above the bottom frame, a hydraulic oil tank 7 is arranged on the rear side above the bottom frame, a fuel tank is arranged in front of the engine, and a concave cavity is integrated on the fuel tank 5, and the concave cavity is a battery storage box, and the battery 6 is fixed in the battery storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com