Production Technology of High Elastic Leather Base Fabric

A production process and leather base fabric technology, applied in the direction of knitting, single-component polyester artificial filament, roughening, etc., can solve the problems of low production efficiency, high production cost, environmental pollution, etc., to improve production efficiency and reduce Environmental pollution, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A production process of high elastic leather base cloth, comprising the following steps:

[0043] 1. Preparation of raw material colored silk

[0044] The preparation method of raw material color silk comprises the following steps:

[0045] 1) Use PET slices for vacuum drying, the drying temperature is controlled at 155°C, and the moisture content of the dried PET slices is ≤0.0025%;

[0046] 2) The dried PET chips and masterbatch are mixed in a certain proportion and put into the screw extruder for melting, and the melting temperature is controlled between 290°C and 295°C;

[0047]3) Put the extruded dyed yarn into the spinning box, and carry out spinning process through the spinneret, and the temperature in the spinning box is controlled between 290°C and 295°C;

[0048] 4) Cool the colored yarn after spinning, and the surface temperature of the colored yarn drops to 50°C;

[0049] 5) Carry out oiling operation on the surface of colored silk;

[0050] 6) Take 3500...

Embodiment 2

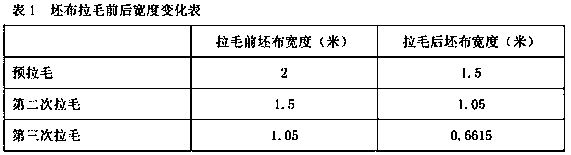

[0077] A production process of high-elastic leather base cloth, the difference from Example 1 is that the drying temperature is controlled at 168°C, the surface temperature of the colored yarn is reduced to 50°C; the temperature of the shaping hot box is controlled at 125°C, and the draft ratio is 1.2 , the temperature of the colored yarn drops to 59°C under the action of the cooling plate, and the oil content of the colored yarn is controlled at 2.7% after passing through the oiling system; the density of the gray cloth obtained after weaving by the circular loom is 14 mesh; The width ratio is 0.8, the shrinkage ratio of the second napping is 0.74, and the shrinkage ratio of the third napping is 0.73; the drying room is controlled at 220°C, and the ratio of the entrance width to the exit width of the drying room track is 0.53. It forms an included angle of 0.8° with the advancing direction of the napped cloth.

Embodiment 3

[0079] A production process of high-elastic leather base cloth, the difference from Example 1 is that the drying temperature is controlled at 160°C, the surface temperature of the colored thread is dropped to 45°C, and the colored thread is wound up with 3600 meters as a roll; the deformation heat The temperature of the box is controlled at 180°C, the temperature of the shaping hot box is controlled at 123°C, the draft ratio is 1.18, the temperature of the colored yarn drops to 57°C under the action of the cooling plate, and the oil content of the colored yarn is controlled at 2.5 after passing through the oiling system %; the gray cloth density obtained after circular loom weaving is 13 meshes; the shrinkage ratio of the control gray cloth in the pre-napping is 0.77, the shrinkage ratio of the second napping is 0.72, and the shrinkage ratio of the third napping is 0.68; The drying room is controlled at 200°C, the chain transmission speed is 85 yards, the ratio of the entrance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com