3D optical grating flexible glue printing technology

A soft glue, 3D technology, applied in the field of 3D pattern printing, can solve the problems of high precision requirements, complicated preparation process, high scrap rate, etc., and achieve the effect of broadening the application range and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

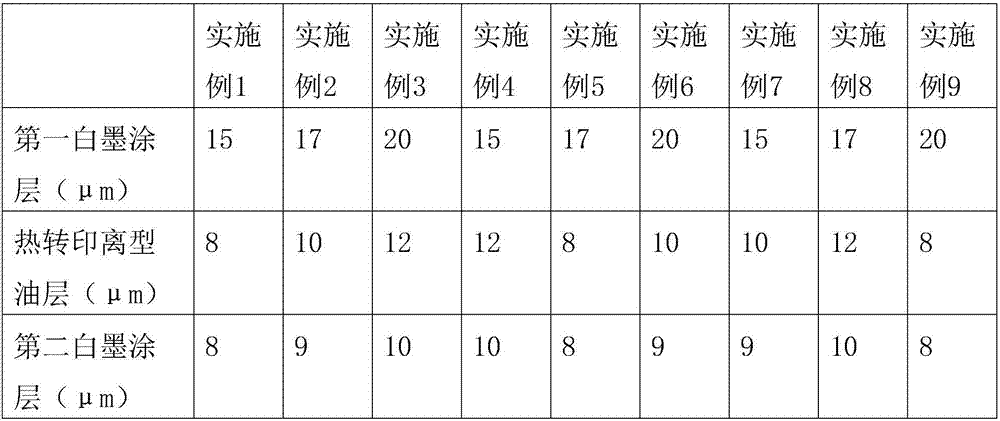

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0024] The product of the present invention first prints multi-angle dynamic patterns / patterns on specially treated coated paper offset printing, and then covers the multi-angle dynamic patterns / patterns with PVC / TPU soft film, and then uses the grating mold to directly print on the soft film The grating pattern is hot-pressed on the top, and the multi-angle dynamic pattern / pattern is successfully and completely transferred on the soft film. The multi-angle dynamic pattern / pattern can show a 3D stereoscopic effect when viewed from different angles. Tear off the coated paper and then add it to the silk screen White ink layer with curing agent. The specific printing process is as follows:

[0025] (1) Screen pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com