Forming method for low-temperature-resistant flexible connector for solid rocket engine

A low-temperature flexible, solid rocket technology, applied in the field of structural parts molding, can solve the problems of lower production efficiency and product quality, low strength of cold-bonded interface, narrow applicable temperature range of connecting parts, etc., and achieve improved production efficiency and product quality, good Mechanical properties and manufacturability, and the effect of improving field adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

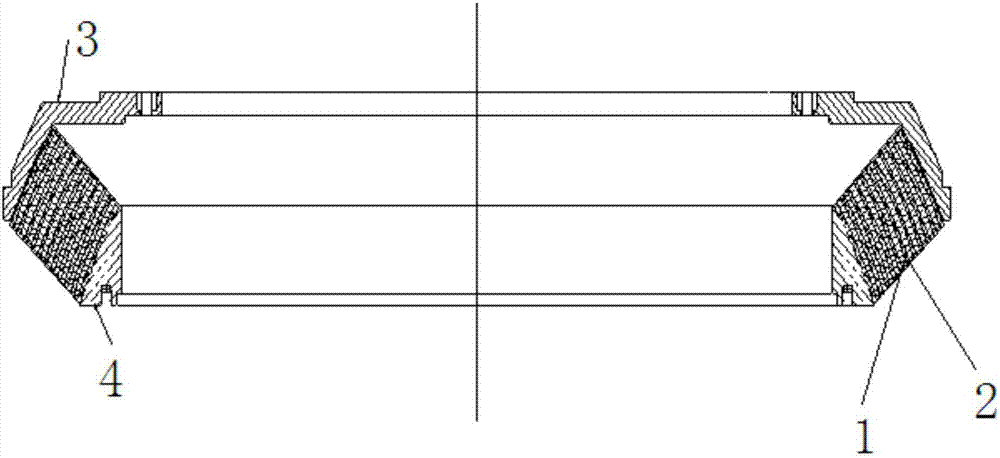

[0024] For such as figure 1 For a certain type of flexible joint shown, the forming process includes the following steps:

[0025] 1) According to the requirements of the flexible joint structure, 10 concentric ring-shaped metal reinforcements 1 with a thickness of 3 mm and different diameters are processed. The metal reinforcements 1 are processed from 30CrMnSiA forgings. According to the structure of the flexible joint, 30CrMnSiA forgings are used to process the fixed rear joint 4 and the movable inverted cone shell 3, and 16 threaded holes are evenly distributed on the end surface. The low-temperature-resistant butadiene is produced into sheets using an open mill, and 11 annular elastic members 2 with a thickness of 2.0-2.10 mm are cut out according to the size requirements.

[0026] 2) Perform sandblasting on both sides of the metal reinforcement, joints after fixing, and the adhesive surface of the movable inverted cone shell, and clean the metal reinforcement after sand...

Embodiment 2

[0034] A method for forming a low-temperature-resistant flexible joint for solid rocket motors, comprising the following steps:

[0035] 1) According to the requirements of the flexible joint structure, a plurality of concentric ring-shaped metal reinforcements with a thickness of 3 mm and different diameters are processed. The metal reinforcements are processed from 30CrMnSiA forgings. According to the flexible joint structure, the fixed rear joint and movable inverted cone shell are processed by 30CrMnSiA forging, and the end surface is evenly distributed with threaded holes. Use an open mill to produce low-temperature-resistant butadiene sheets, and cut out multiple annular elastic parts with different diameters and thicknesses of 2.0-2.10mm according to the size requirements.

[0036] 2) Perform sandblasting on both sides of the metal reinforcement, joints after fixing, and the adhesive surface of the movable inverted cone shell, and clean the metal reinforcement after san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com