Duplex double-circulating under-balanced drilling technology

An underbalanced drilling and double-circulation technology, which is applied to drilling equipment, driving devices for drilling in boreholes, drill pipes, etc., can solve problems such as high equipment costs, sticking of bonded drilling tools, and complex geological structures, and avoid Borehole wall collapse and the effect of increasing drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

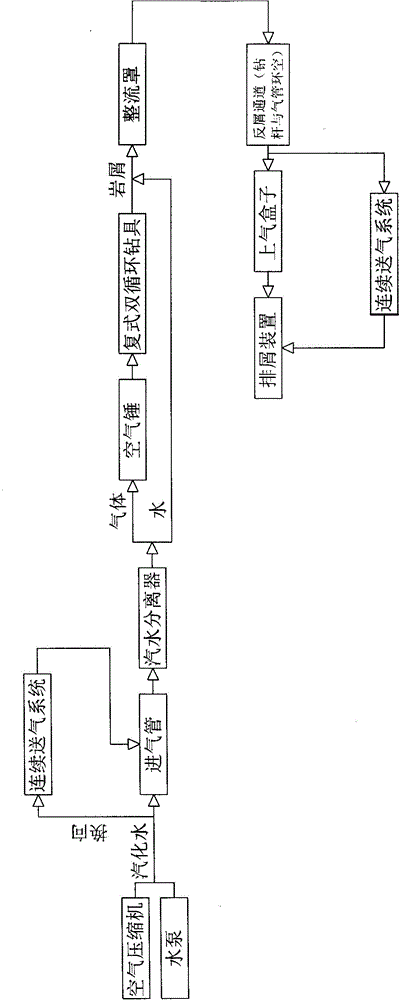

[0011] The compound double-circulation underbalanced drilling technology of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings.

[0012] See figure 1 , compound double circulation underbalanced drilling process, according to the following steps:

[0013] (1) Drilling: start the air compressor and water pump, and vaporized water is formed in the pipeline, and the vaporized water enters the steam-water separator through the intake pipe, and the separated gas drives the air hammer to drive the compound double-circulation drilling tool to work, and the separated water The cuttings formed during the working process of the compound double-circulation drilling tool are mixed into mud, pass through the fairing, and return to the upper air box through the anti-chip channel formed by the annular space between the drill pipe and the intake pipe, and finally discharged by the chip removal device.

[0014] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com