A kind of preparation method of co@c@mof magnetic catalyst and its application

A magnetic catalyst and reaction technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of complete recovery and difficult catalysts, and achieve the effects of rapid separation, high conversion rate and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

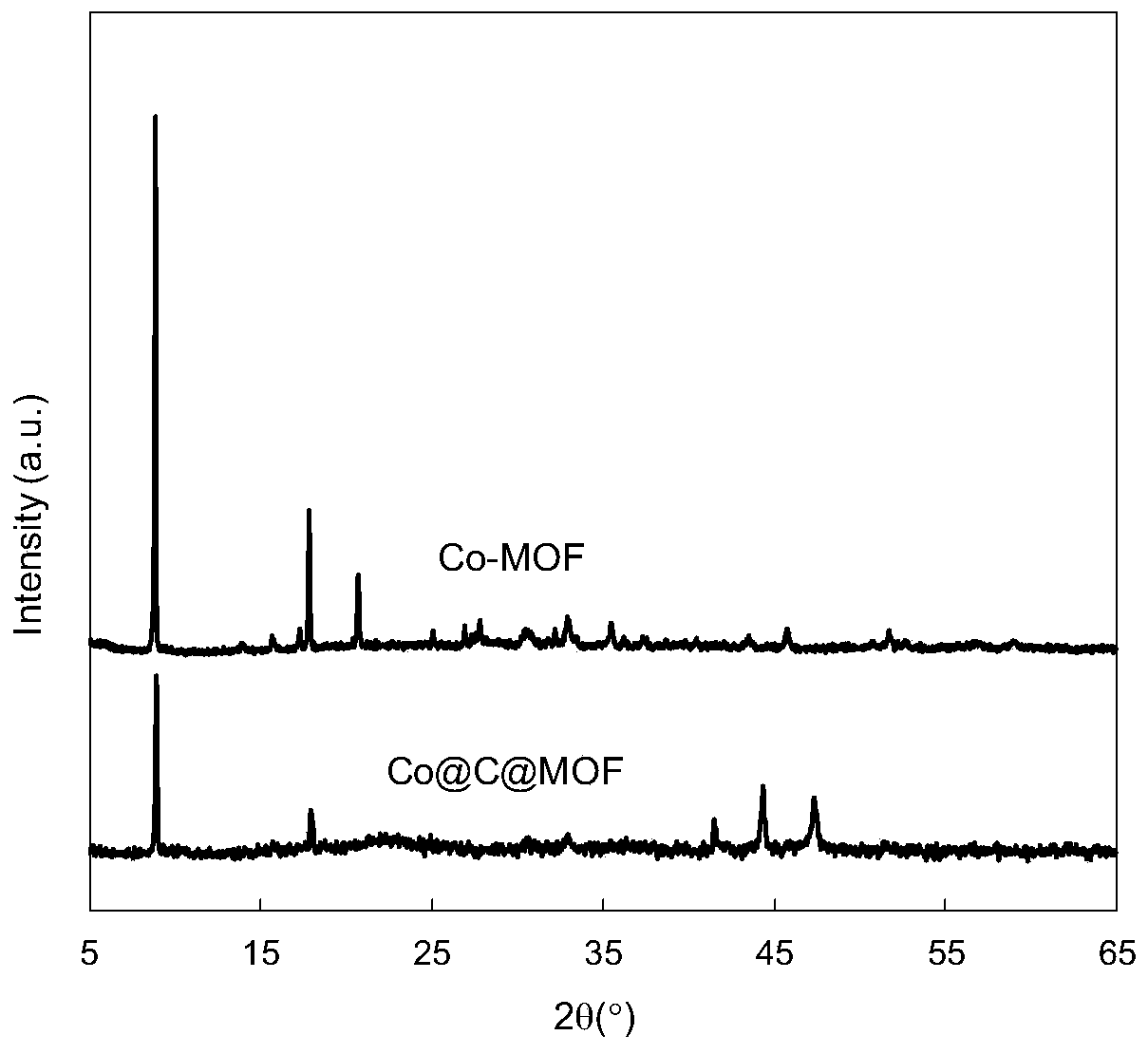

[0034] (1) The preparation method of Co@C@MOF magnetic catalyst, including the following steps:

[0035] Add 2.988g cobalt acetate, 0.3mL hydrofluoric acid (40% mass concentration), 2.0g terephthalic acid (cobalt acetate: hydrofluoric acid: terephthalic acid: water = 1:1:1:278), add Stir and mix in 60g of water, then add the closed reaction kettle, put the closed reaction kettle in an oven for static hydrothermal crystallization at 220°C for 24 hours, after the reaction, cool down to room temperature to obtain the reaction production liquid; take the reaction production liquid through the second One suction filtration treatment, the filter cake was first washed with 20mL of N,N'-dimethylformamide (DMF) at 60°C for one time, then suction filtered, and then washed with 40mL of absolute ethanol at 60°C 1 time, after the second suction filtration treatment and drying treatment, the Co-MOF metal organic framework material was obtained;

[0036] Put the metal-organic framework mate...

Embodiment 2~14

[0040] In Examples 2-14, according to the technical solution provided by the present invention, the ratio of raw materials is adjusted within the given range, and the performance of the obtained products is equivalent. The implementation process is the same as in Example 1 except for the following differences, and the relevant results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com