Anti-radiation composite cable based on magnesium aluminate spinel insulation

A magnesium-aluminum spinel and composite cable technology, which is applied in the direction of power cables, inorganic insulators, cables, etc., can solve the problems of insulated cables that are easy to absorb moisture and reduce insulation performance, and achieve the effect of solving the decline in insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

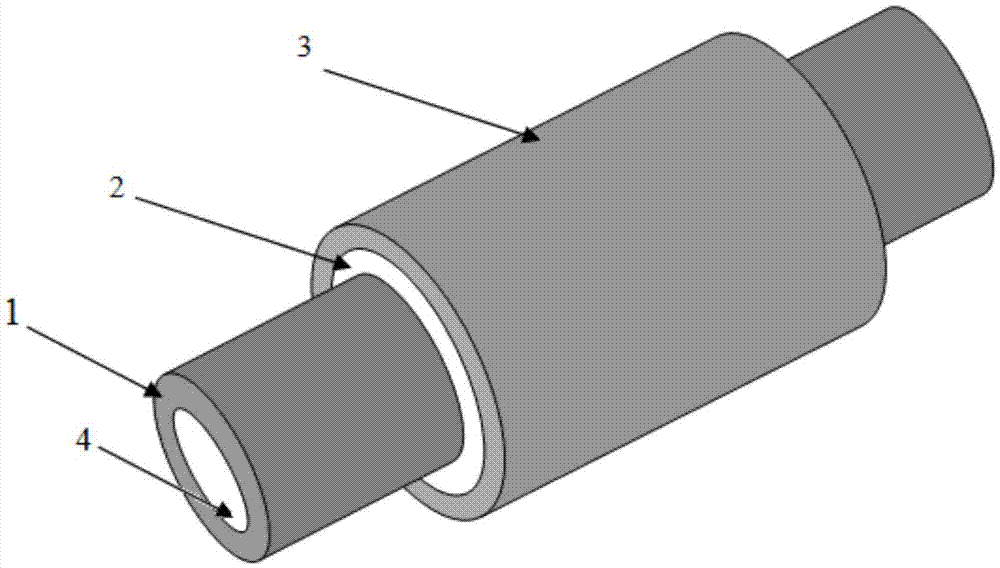

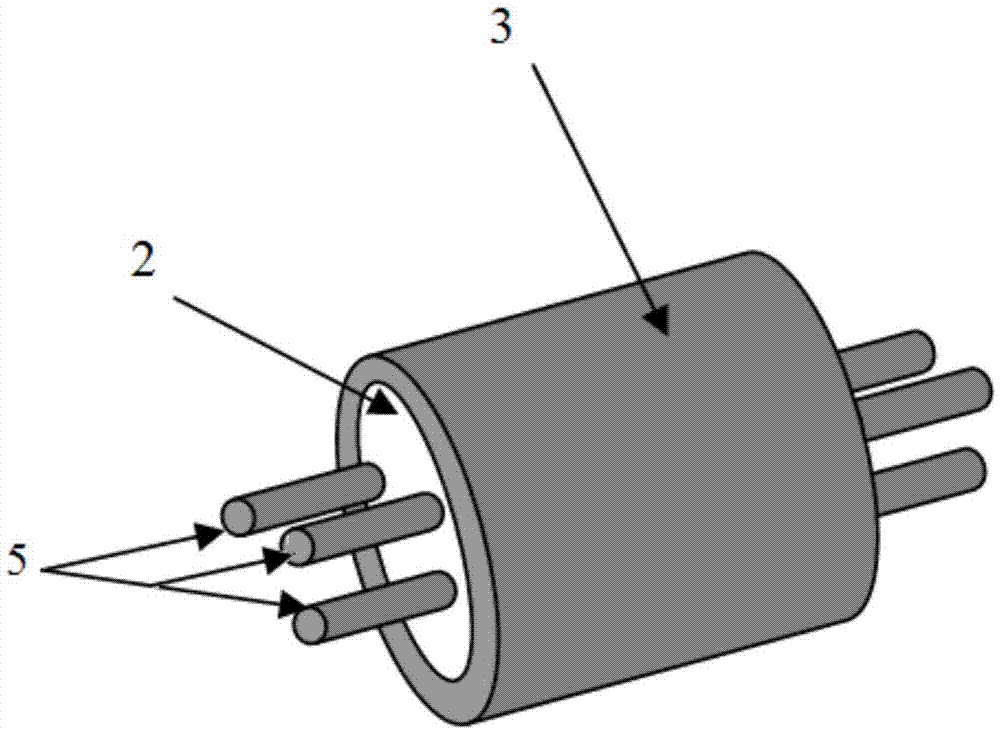

[0019] Such as figure 1 As shown, in the first embodiment, the radiation-resistant composite cable based on magnesium-aluminum spinel insulation provided by the present invention includes a metal conduit 1 , a magnesium-aluminum spinel insulation layer 2 , and a metal armor 3 from the inside to the outside. The exterior of Metal Armor 3 is a vacuum environment. The hollow part of the metal conduit 1 is a cooling channel 4 . The cooling channel 4 is filled with coolant to actively cool the metal conduit 1 .

[0020] Coolant can choose water, CO2, helium. The metal armor 3 can be selected from austenitic stainless steel, martensitic stainless steel, nickel-based alloy; the metal conductor 1 can be selected from oxygen-free copper, zirconium chromium copper, and stainless steel. The main compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com