Single-slip large diameter bridge plug and setting method thereof

A large-diameter, single-slip technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well parts, etc., can solve the problems of difficult and time-consuming drilling and grinding, and achieve large internal diameter and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the drawings and embodiments.

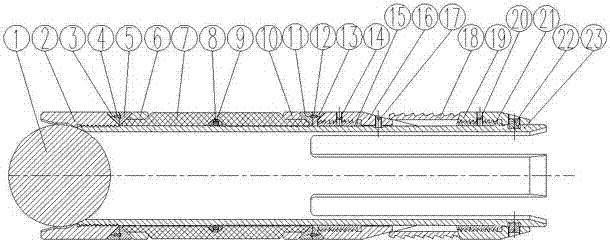

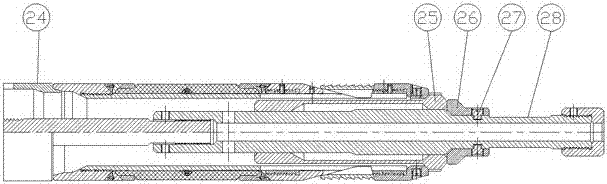

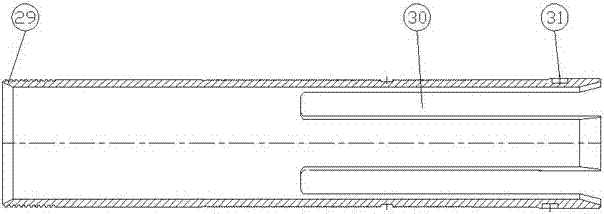

[0033] This embodiment provides a single slip large diameter bridge plug, such as Figure 1~Figure 2 As shown, it includes the upper joint 2, the one-way tooth integral slip 18, the central tube 23, the rubber tube 7, the cone 16 and the guide shoe 19. The central tube 23 is an axial hollow structure, and the rubber tube 7 is sleeved on the central tube 23 On the outer wall, the bottom section of the cone 16 is tapered, wedged into the gap between the one-way tooth integral slip 18 and the central tube 23. The upper cavity of the central tube 23 has a variable diameter cavity for placing the soluble ball 1 29, such as image 3 As shown, the inner diameter of the reducing cavity 29 is reduced from top to bottom. The cross-section of the reducing cavity 29 is a conical surface with a taper of 15°-30°. The inner diameter of the center tube 23 is not less than 71mm at the sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com