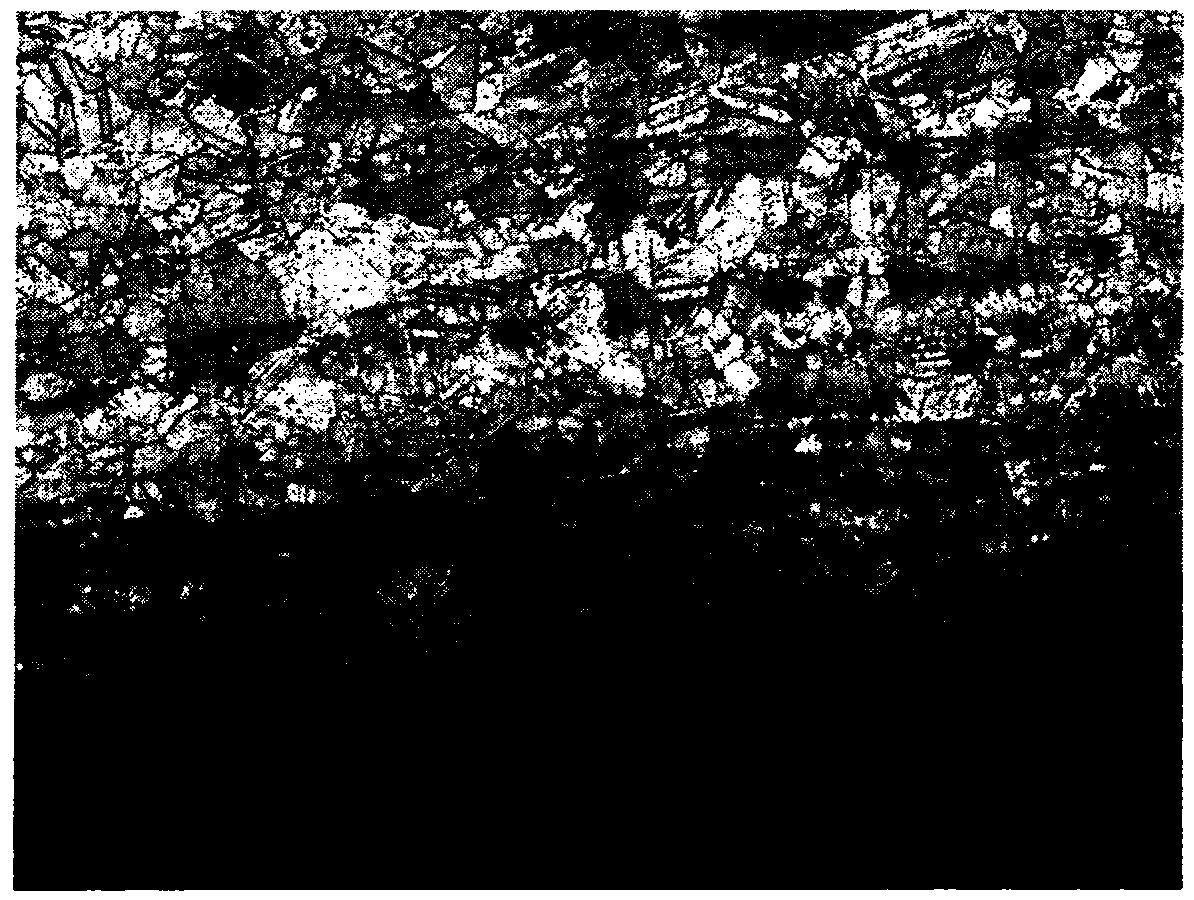

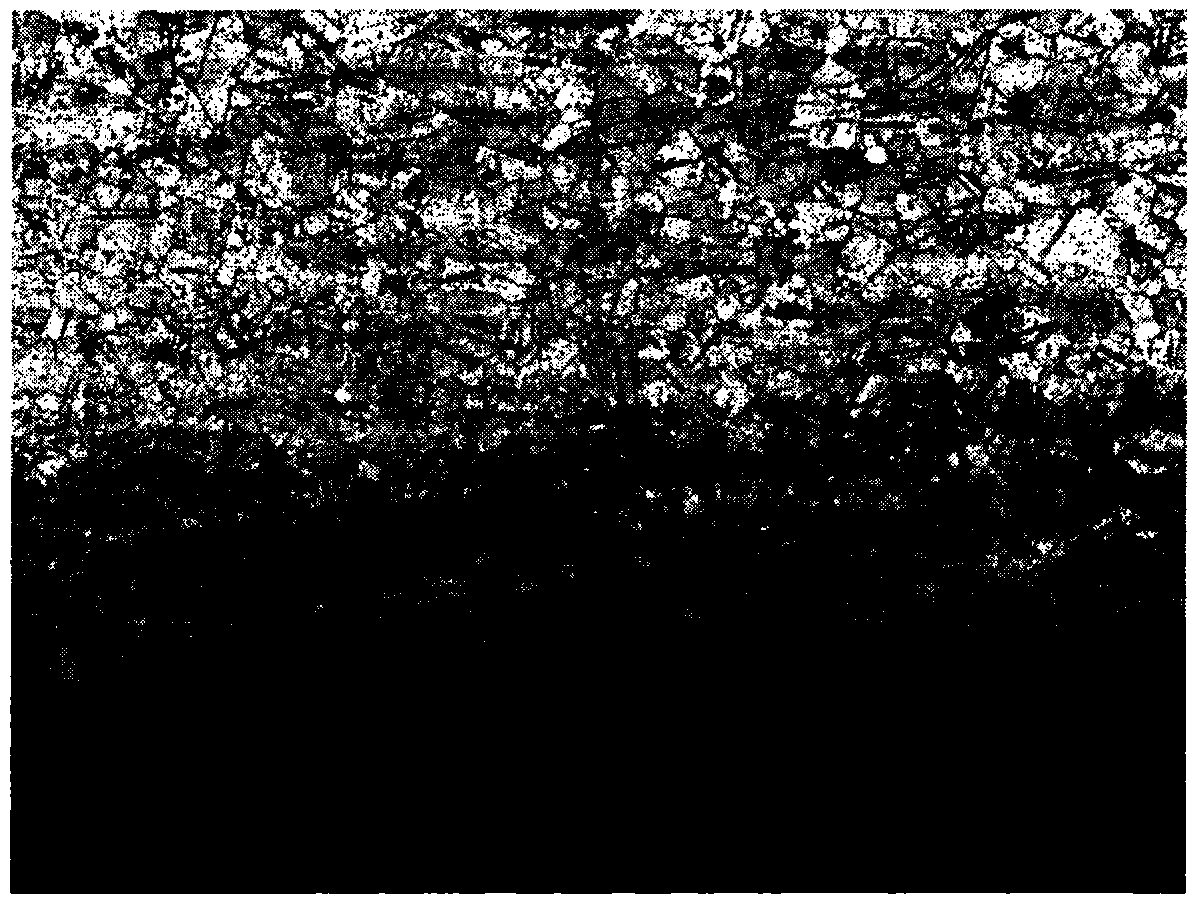

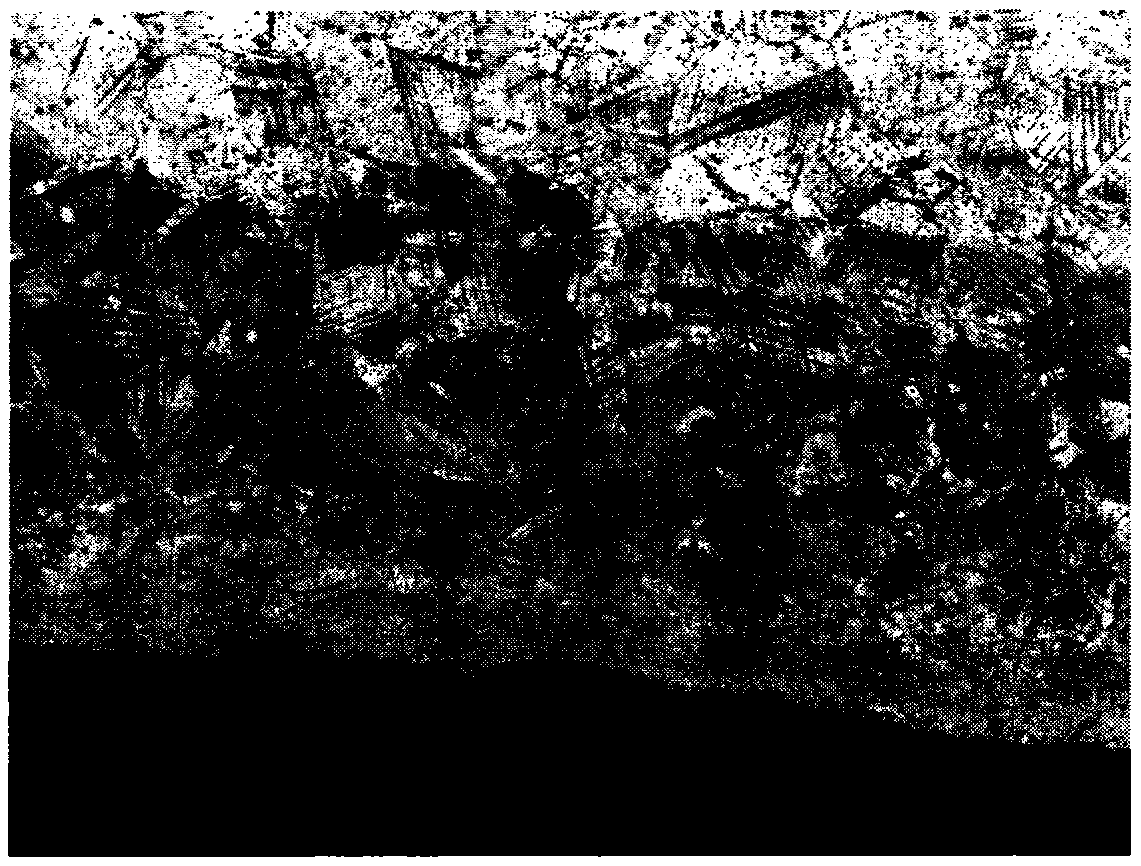

A corrosive agent showing the slip zone structure of the shot peening layer

A slip zone and corrosive agent technology, applied in the field of etchant, can solve the problems affecting the measurement of the depth of the slip zone, and cannot clearly show the slip zone of the shot peening layer, etc., and achieve a good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A corrosive agent showing the slip zone structure of the shot peening layer, the formula of which is shown in Table 2.

[0016] Table 2

[0017] h 2 o

FeCl 3 ·6H 2 o

CuCl 2 2H 2 o

Brogeramine

45mL

50mL

35g

5.5g

19mL

2mL

2 drops

[0018] Wherein, the mass concentration of hydrochloric acid is 38%, and the mass concentration of nitric acid is 68%.

[0019] The preparation method is as follows:

[0020] Add distilled water to the beaker first, then add FeCl in sequence 3 ·6H 2 O, CuCl 2 2H 2 O, fully stir the FeCl 3 ·6H 2 O and CuCl 2 2H 2 O until uniformly dissolved; then add hydrochloric acid, stir evenly, then add nitric acid and bromogeramine, and finally drop in hydrogen peroxide and mix evenly.

[0021] experiment method:

[0022] Process the TP347H stainless steel that has been shot-peened on the inner wall into a metallographic sam...

Embodiment 2-3

[0024] According to the same method as in Example 1, the formula in Table 2 was used to corrode the austenitic stainless steel pipe with shot peening on the inner wall. The corrosion effect of the shot peening layer was good, and the microstructure of the shot peening layer could be clearly displayed.

[0025] Formulation and corrosion effect of table 2 embodiment 1-3

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com