Method for passing hemicellulose through continuous flow microchannel reactor to prepare xylose

A technology of microchannel reactor and channel reactor, which is applied in the direction of sugar production, xylose production, application, etc., to achieve the effects of avoiding side reactions, improving reaction efficiency, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

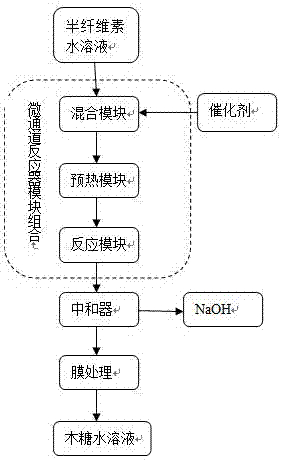

[0029] For the continuous flow microchannel reactor (straight channel functional module + "heart-shaped" structural functional module), the connection mode of the microchannel reactor is determined, and the number of mixed reaction modules is determined according to the flow rate and reaction residence time; the heating medium is heat transfer oil. Specific process reference figure 1 .

[0030] Firstly, the aqueous solution or 70-80% solid matter recovered from chemical fiber waste liquid with a hemicellulose content of 15-25% is made into the 12% mass concentration required for the reaction; then the configured hemicellulose aqueous solution and sulfuric acid are passed through After mixing in the mixing module, it is passed into the straight channel of the microchannel reactor for preheating. The set temperature is controlled by an external heat exchanger, and the heat exchange medium is heat transfer oil, and then the flow rate of the hemicellulose aqueous solution is chang...

Embodiment 2

[0037]First, the hemicellulose solution recovered from chemical fiber waste liquid with a content of 15-25wt% is configured to the mass concentration of 12wt% required for the reaction; the hemicellulose aqueous solution and hydrochloric acid required for the reaction are first passed into the mixing module for mixing After that, it is passed into the straight channel of the microchannel reactor for preheating. The set temperature is controlled by an external heat exchanger. The heat exchange medium is heat transfer oil, and then the flow rate of the hemicellulose aqueous solution is controlled by the flow rate of 20ml / min; the flow rate of the catalyst sulfuric acid is 0.3 mL / min;

[0038] After entering the mixing module synchronously through the respective metering pumps for mixing, the preheating module then enters the enhanced mass transfer module for mixing reaction, and the reaction temperature is controlled by an external heat exchanger. After mixing and hydrolysis rea...

Embodiment 3

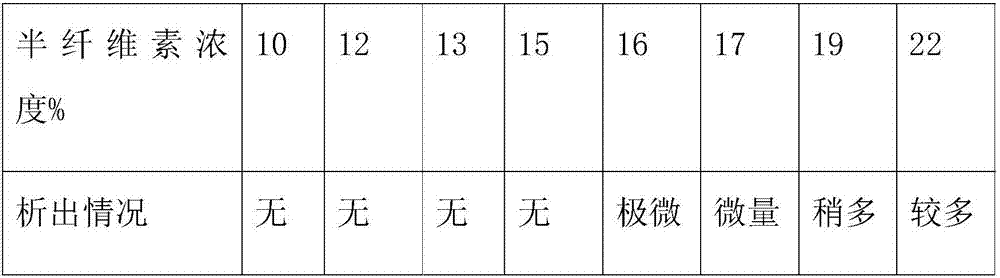

[0041] The steps and parameters of this example are consistent with those of Example 1, only the concentration of the hemicellulose solution when the raw materials are prepared is changed. In order to ensure that the reaction is carried out normally in the continuous flow microreactor, we did a precipitation test after mixing different hemicellulose concentrations with sulfuric acid, and the results are shown in the following table:

[0042]

[0043]

[0044] It is suitable to select hemicellulose concentration of 12wt% from the table above, and no solid matter will be precipitated during the reaction process, which can ensure the smooth progress of the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com