A kind of technique of low-pressure oxo synthesis of acetic anhydride

An oxo synthesis and acetic anhydride technology, applied in the preparation of carboxylic anhydride, organic chemistry, etc., can solve the problems of many side reaction products, short production cycle, complicated side reactions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

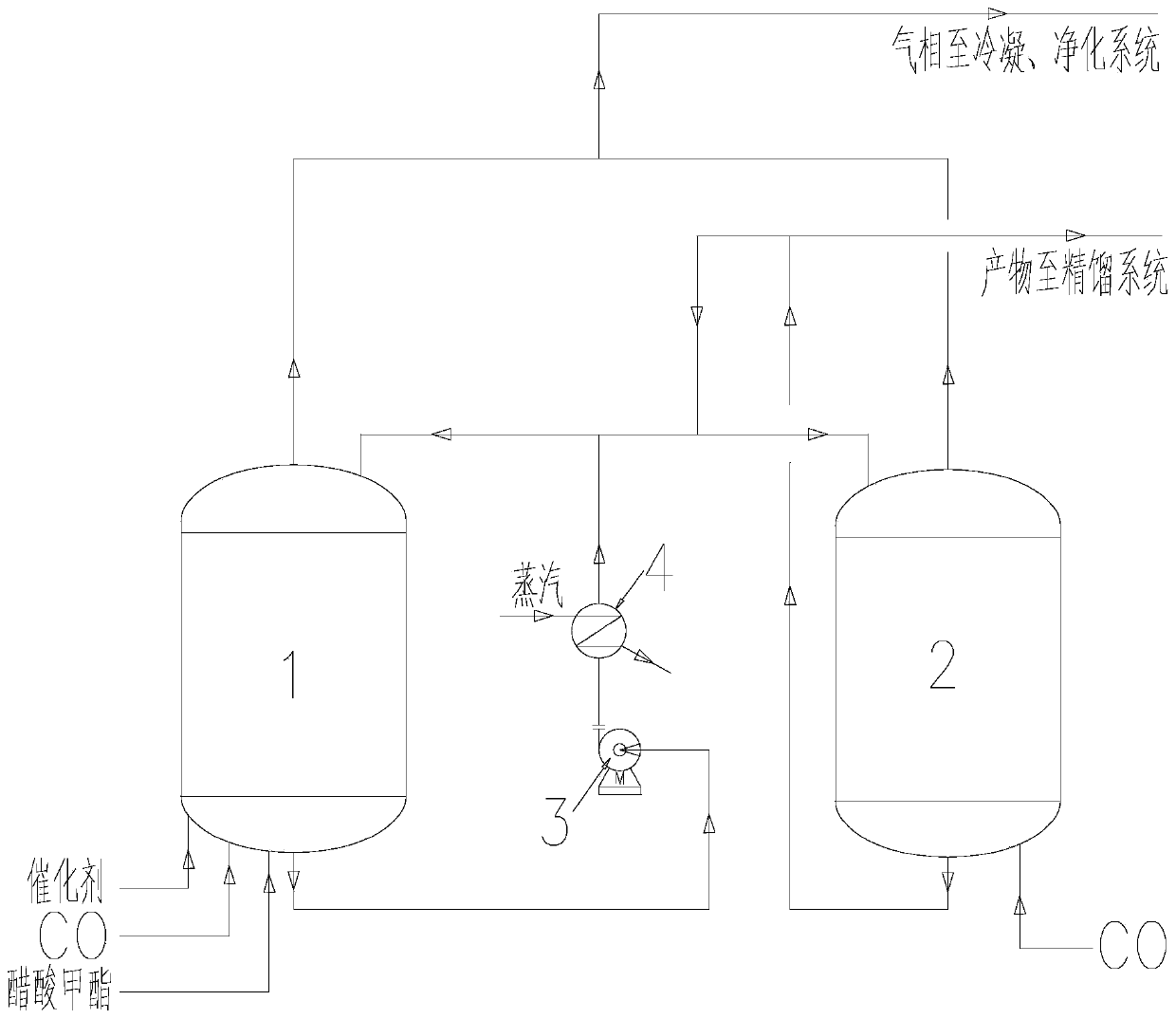

[0041] A system for low-pressure carbonylation of acetic anhydride, such as figure 1 As shown, the reactor group is included, and the reactor group is a series assembly of the first reactor 1 and the second reactor 2, and a pump 3 and a heat exchanger 4 are arranged between the first reactor 1 and the second reactor 2 , carbon monoxide, methyl acetate and catalyzer enter from the first reactor 1, the material at the bottom of the first reactor 1 is taken out by the pump 3 and enters the second reactor 2 through heat exchanger 4 heating, and the material in the second reactor 2 The product is passed into the rectification system, and the second reactor 2 is provided with a pipeline for feeding carbon monoxide.

[0042] Part of the material flowing out from the heat exchanger 4 is sent to the second reactor 2 , and the other part is sent to the first reactor 1 .

[0043] Both the tops of the first reactor 1 and the second reactor 2 are provided with exhaust lines. Each exhaust...

Embodiment 2

[0053] This embodiment is the same as Embodiment 1, the difference is:

[0054] The pressure of the first reactor 1 is 3.8MPa, the temperature is 175°C, and the catalyst concentration is 150ppm;

[0055] The second reactor 2 has a pressure of 3.5 MPa, a temperature of 175° C., and a catalyst concentration of 150 ppm.

Embodiment 3

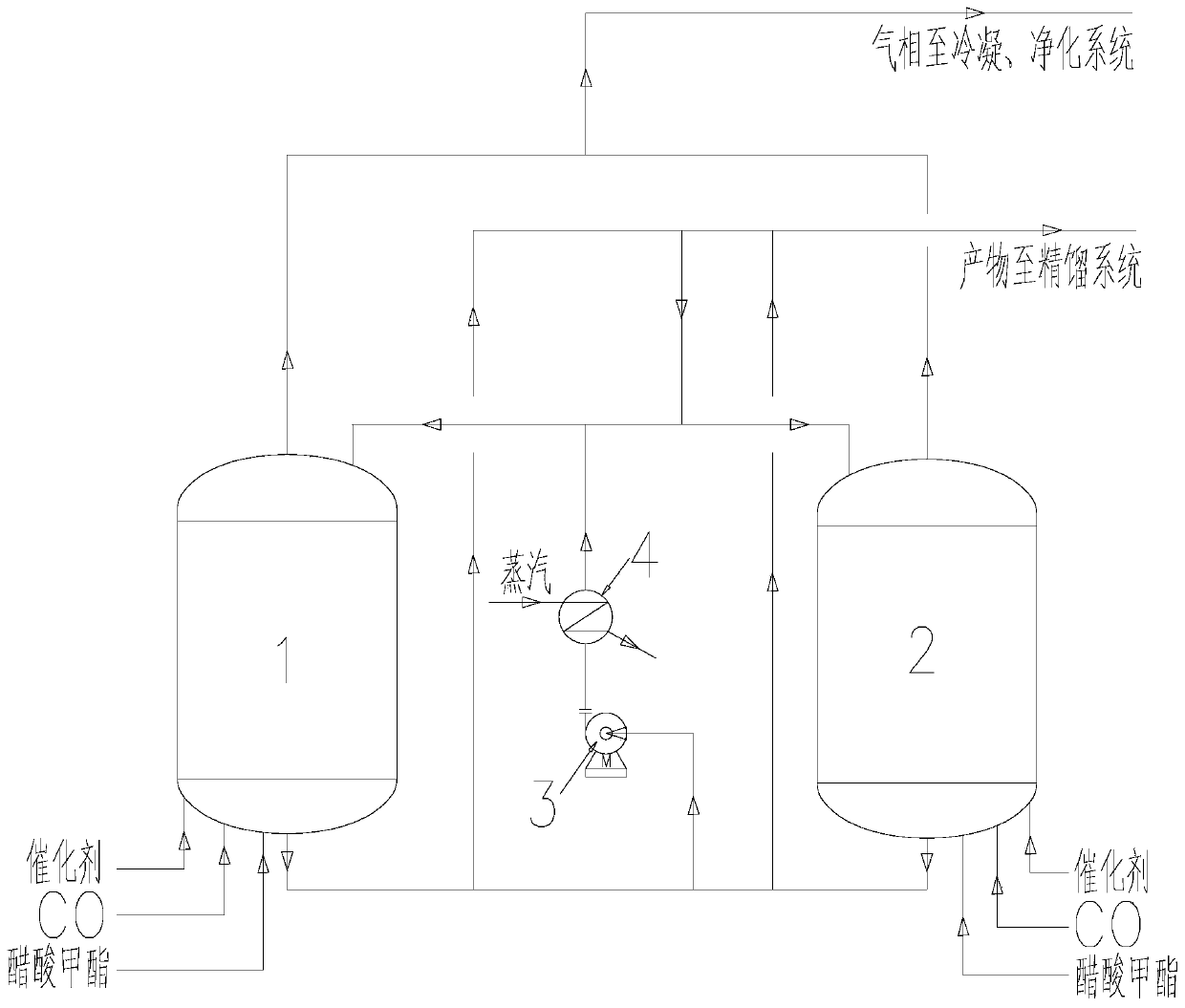

[0057]A system for low-pressure carbonylation of acetic anhydride, such as figure 2 As shown, it includes a reactor group, a pump and a heat exchanger. The reactor group is a parallel assembly of the first reactor 1 and the second reactor 2, and carbon monoxide, methyl acetate and catalyst enter the first reactor 1 and the second reactor. In the second reactor 2, the material at the bottom of each reactor is pumped out by the pump 3 and then heated by the heat exchanger 4 and returned to the first reactor 1 and the second reactor 2. The first reactor 1 and the second reactor The product in kettle 2 is passed to the rectification system.

[0058] Both the tops of the first reactor 1 and the second reactor 2 are provided with exhaust lines.

[0059] Each exhaust line is connected to a condenser.

[0060] A kind of technology of low-pressure carbonylation acetic anhydride, as follows:

[0061] Carbon monoxide, methyl acetate, and the catalyst enter the first reactor 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com