A method of adding surfactant-assisted ball milling to prepare β-tricalcium phosphate powder

A technology of surfactant and tricalcium phosphate powder, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of β-tricalcium phosphate multi-impurity phase, imbalance of calcium-phosphorus atomic ratio, wide range of particle size distribution, etc. problems, to achieve the effect of solving the imbalance of raw material ratio, sufficient solid phase reaction and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Measure 1% of surfactant KW-300 into ethanol and ultrasonically disperse for 10 minutes. The proportion of ethanol is 0.5% of the total weight of calcium and phosphorus raw materials. Take by weighing 49.58g calcium hydrogen phosphate (CaHPO 4 2H 2 O) and 14.42g calcium carbonate (CaCO 3 );

[0029] (2) Transfer the raw materials and ethanol containing surface activity into the ball milling tank together, and ball mill and mix them for 3 hours at a speed of 300 r / min on the planetary ball mill, and the powder raw materials after mixing will not stick to the tank and balls;

[0030] (3) place the mixed slurry in an oven to dry at a temperature of 50° C. to remove ethanol, and then pass through a 50-mesh sieve;

[0031] (4) Put the sieved powder into a muffle furnace for calcination at 850° C. for 5 hours to obtain β-tricalcium phosphate powder.

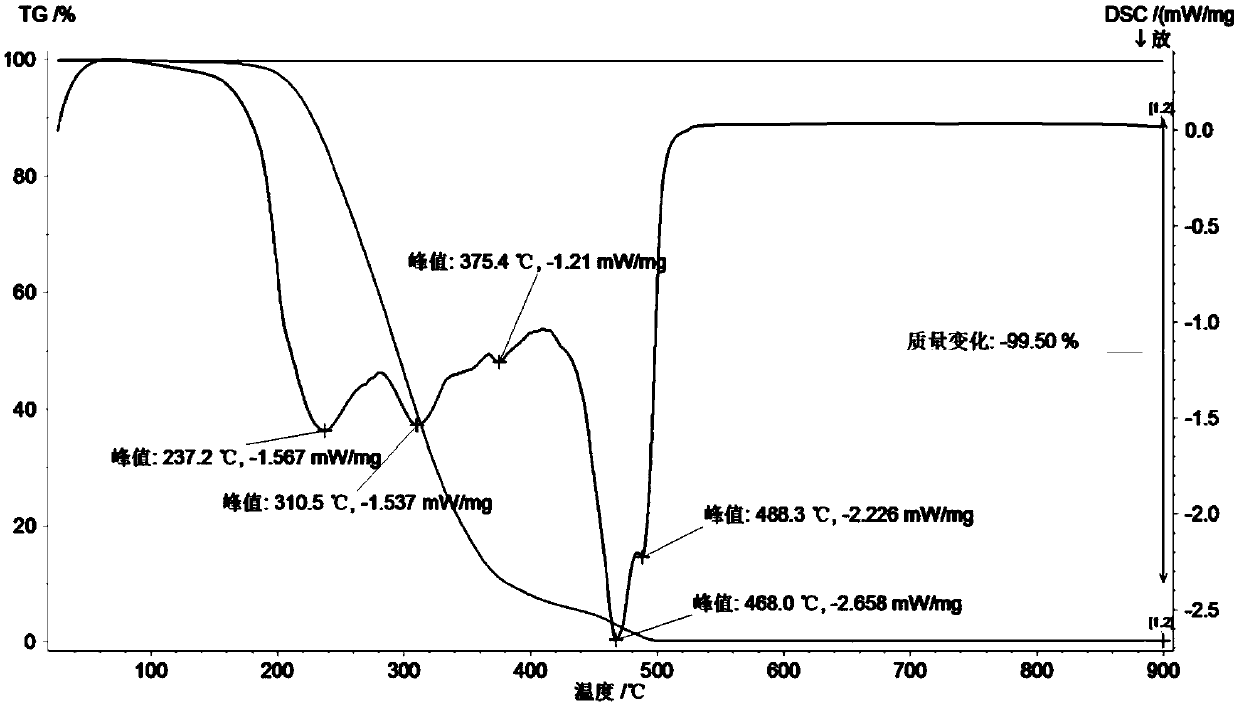

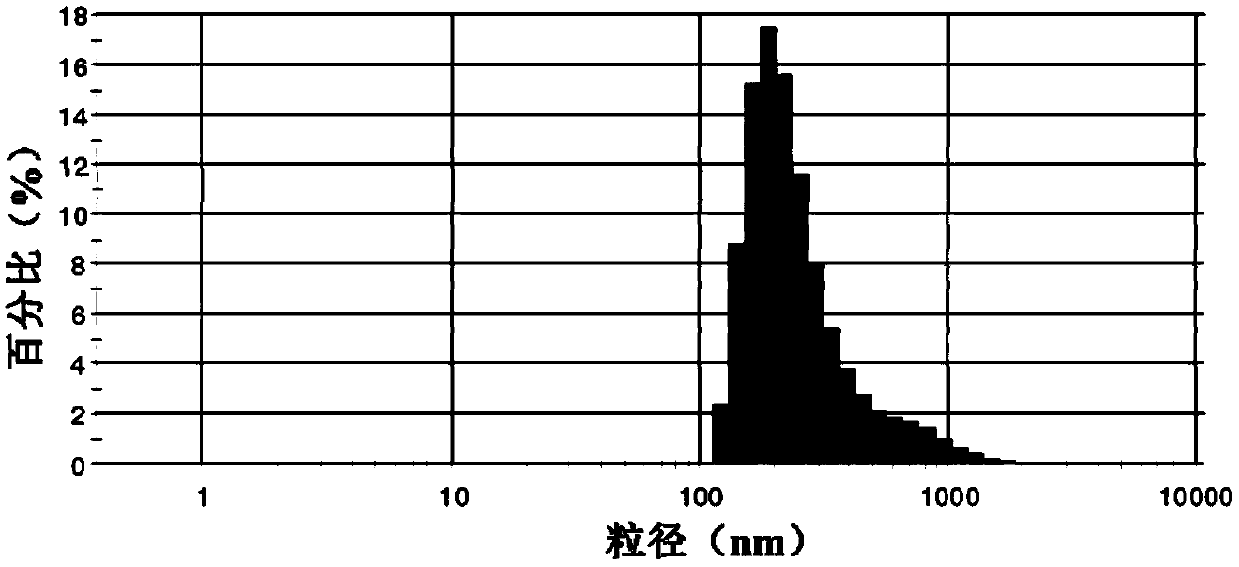

[0032] figure 1 For the TG-DSC curve of the surfactant KW-300 added in this embodiment, it can be seen from the figur...

Embodiment 2

[0035] (1) Measure 2.5% of surfactant KW-300 into ethanol and ultrasonically disperse for 30 minutes. The proportion of ethanol is 1.5% of the total weight of calcium and phosphorus raw materials. Take by weighing 49.58g calcium hydrogen phosphate (CaHPO 4 2H 2 O) and 14.42g calcium carbonate (CaCO 3 );

[0036] (2) Transfer the raw materials and ethanol containing surface activity into a ball mill tank together, and ball mill and mix them for 9 hours at a speed of 400 r / min on a multi-dimensional swing nano ball mill, and the powder will not stick to the tank after mixing;

[0037] (3) place the mixed slurry in an oven to dry at a temperature of 60° C. to remove ethanol, and then pass through a 50-mesh sieve;

[0038] (4) Put the sieved powder into a muffle furnace and calcinate at 900° C. for 3 hours to obtain β-tricalcium phosphate powder.

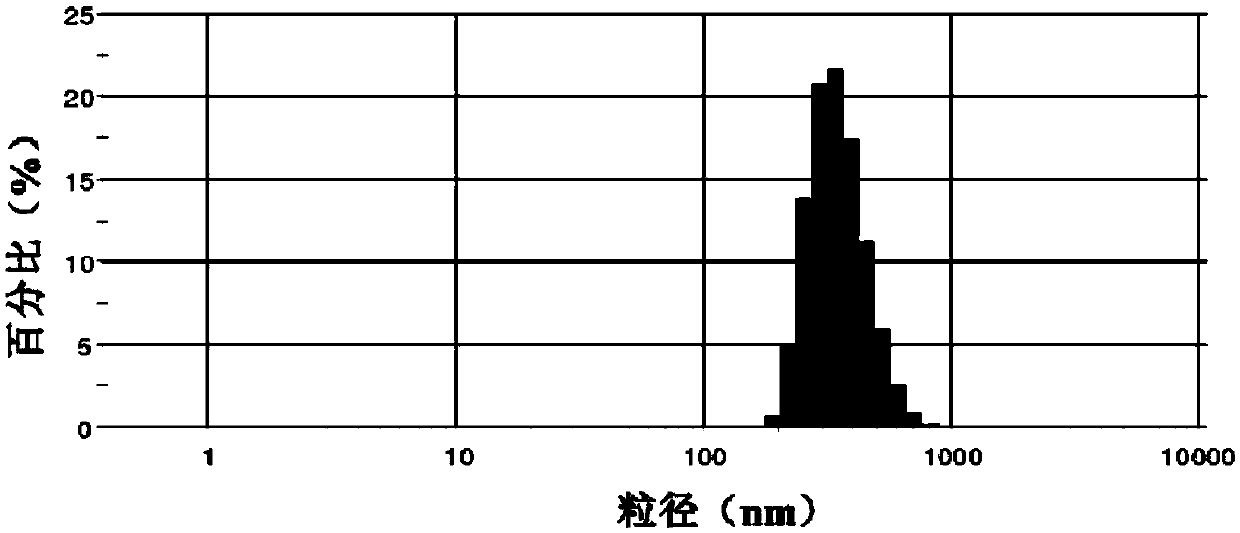

[0039] Figure 4 The XRD spectrum of the β-tricalcium phosphate powder prepared for this example was compared with the standard s...

Embodiment 3

[0041] (1) Measure 5% of surfactant KW-300 into ethanol and disperse it ultrasonically for 25 minutes. The ratio of ethanol is 3% of the total weight of calcium and phosphorus raw materials. Take by weighing 49.58g calcium hydrogen phosphate (CaHPO 4 2H 2 O) and 14.42g calcium carbonate (CaCO 3 );

[0042] (2) Transfer the raw materials and ethanol containing surface activity into a ball mill tank, and ball mill and mix them for 6 hours at a speed of 500 r / min on a planetary ball mill, and the powder will not stick to the tank after mixing;

[0043] (3) Place the mixed slurry in an oven to dry at a temperature of 70° C. to remove ethanol, and then pass through a 50-mesh sieve;

[0044] (4) The sieved powder was put into a muffle furnace and calcined at 950° C. for 3 hours to obtain β-tricalcium phosphate powder.

[0045] The test results of the β-tricalcium phosphate powder prepared in this example are similar to those in Example 1 and Example 2, and will not be repeated h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com