Adaptive blade tip processing table fixture for aero-engine fan blade machining

A technology for aero-engine and fan blades, which is applied to manufacturing tools, workpiece clamping devices, metal processing equipment, etc., can solve problems such as poor practicability, and achieve good practicability and prevent loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

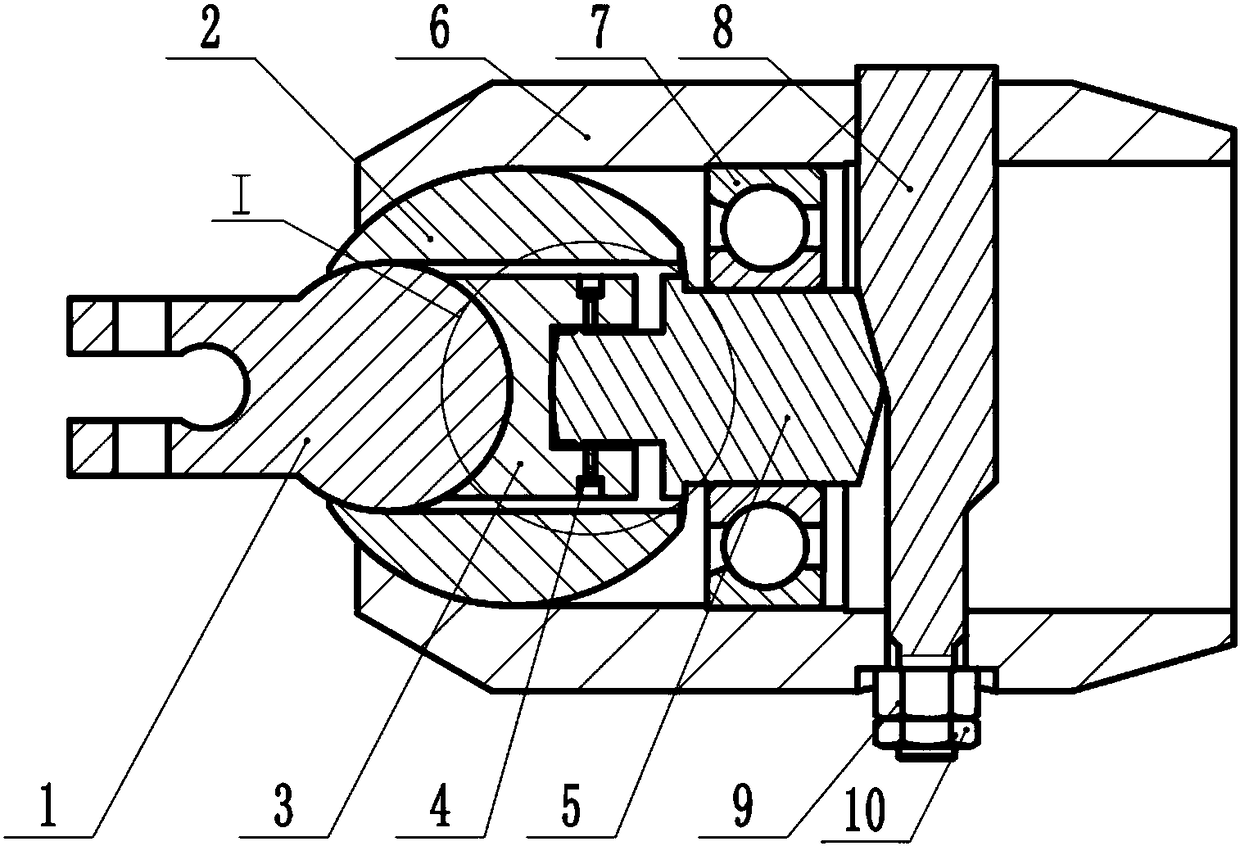

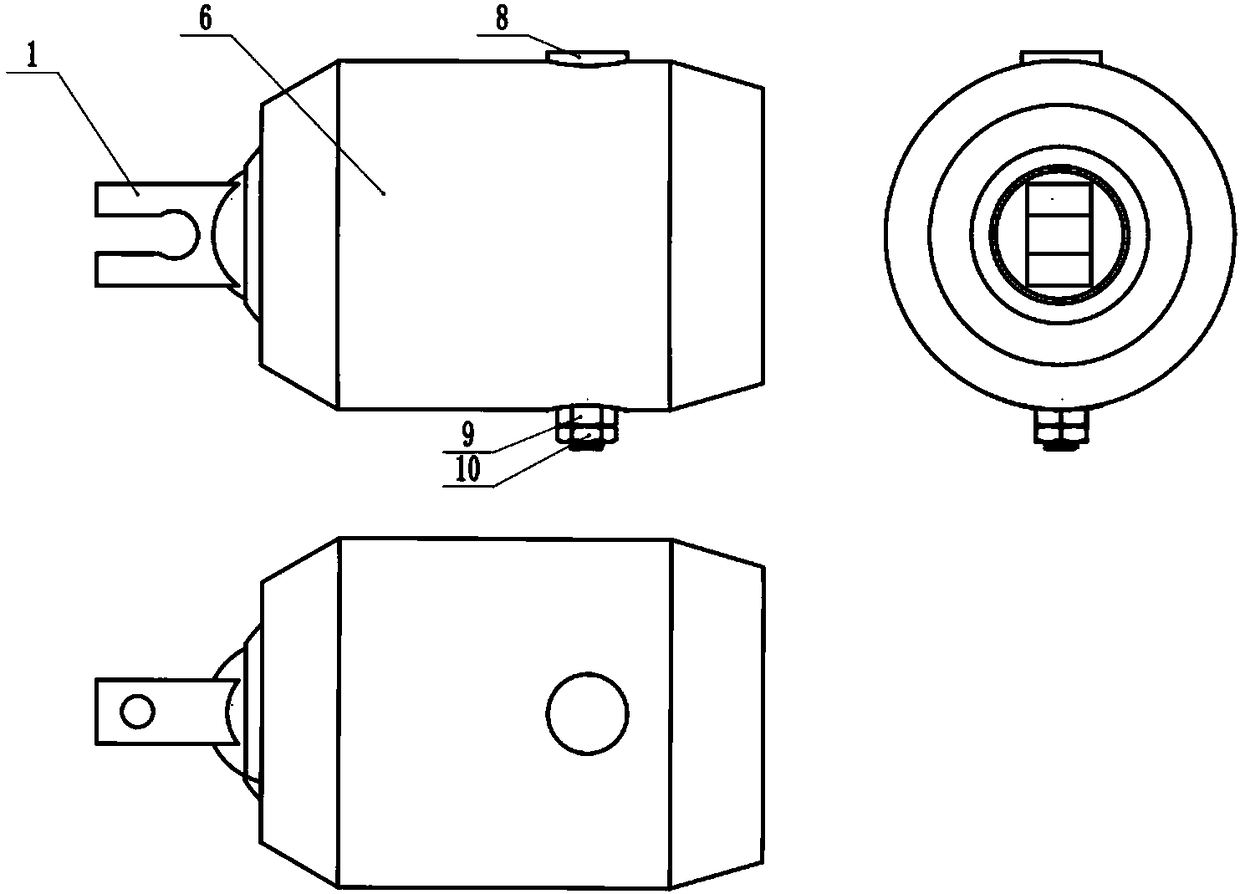

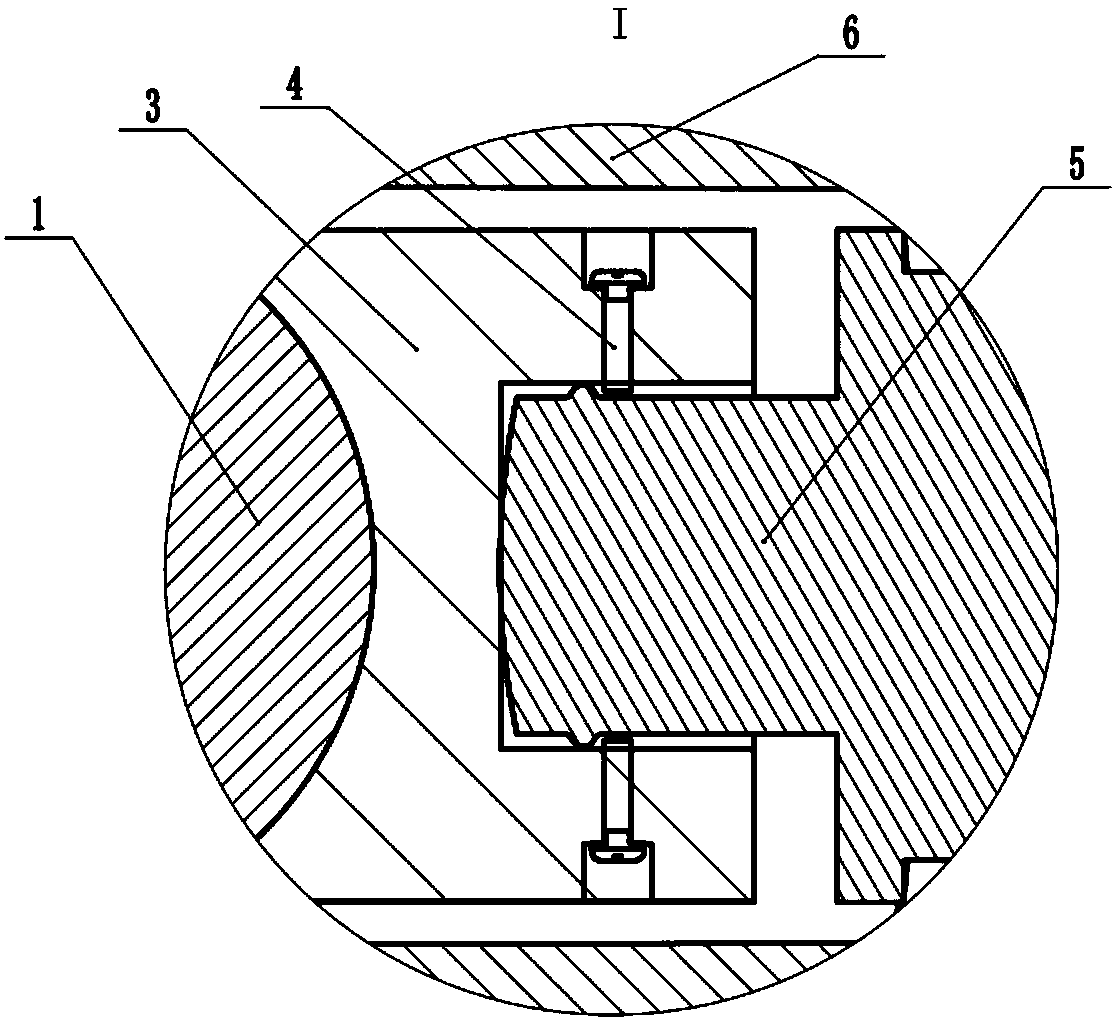

[0017] The following examples refer to Figure 1~4 .

[0018] The self-adaptive blade tip process fixture used in the processing of aeroengine fan blades in the present invention includes a chuck 1, a rolling body 2, a friction block 3, a screw 4, a push rod 5, a casing 6, a bearing 7, a push rod 8, and a hex nut 9 and snap nut 10.

[0019] The front end of the chuck 1 is provided with a bolt hole, and adopts a rigidity-weakened elastic design, and the rear part is designed as a sphere. The center line of the bolt hole is perpendicular to the center plane of the fixture, and the center of the spherical surface of the tail is located on the center plane of the fixture.

[0020] The outside of the rolling body 2 is designed as a sphere, the inner front end is designed as a spherical surface, and is matched with the rear spherical surface of the chuck 1, and the inner rear end is designed as a cylindrical surface.

[0021] The front end of the friction block 3 is designed as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com