Strip steel hot galvanizing production process data high-speed acquisition method

A production process and data acquisition technology, applied in data processing applications, program control, program control systems, etc., can solve problems such as the impact of accurate quality analysis, speed mismatch, high-speed acquisition, etc., to achieve improved acquisition cycle, simple and reliable data acquisition methods , Feasibility and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

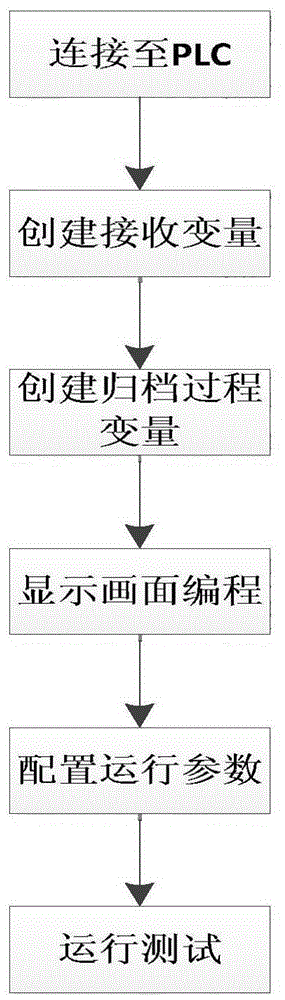

Embodiment 1

[0039] 1) Based on the relevant parameters of the hot-dip galvanizing air knife control, the pressure and angle of the air knife, the distance between the air knife nozzle and the strip steel, the distance between the air knife nozzle and the liquid surface of the zinc pot, the nozzle gap, the running speed of the strip steel, temperature, Plate thickness, plate width, plate shape and surface roughness, zinc pot temperature and chemical composition and other parameters are tracked and analyzed online, and feedback information from users against hot-dip galvanizing quality is collected, and these parameters are observed in the production process to affect the quality of hot-dip galvanizing The impact of the impact, you can first collect the two parameters of the length of the strip and the thickness of the zinc layer, and program them in PLC and WinCC respectively, and observe the change curve of the thickness of the zinc layer as the length of the strip changes. And reserve an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com