Tissue chip making system based on image recognition and positioning and chip making method thereof

A technology of image recognition and tissue chip, which is applied in the field of finger core system and core making, tissue chip core making system and core making with core making system, which can solve the problem of difficulty in ensuring accuracy, reducing chip preparation efficiency and yield, and difficult to guarantee Accuracy and other issues to achieve the effect of reducing errors and work intensity, convenient query and use, and improving core-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the technical solution of the present invention clearer, the CCD-based positioning tissue chip core-making system and method of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to explain the present invention. It is not used to limit the protection scope of the claims of the present invention.

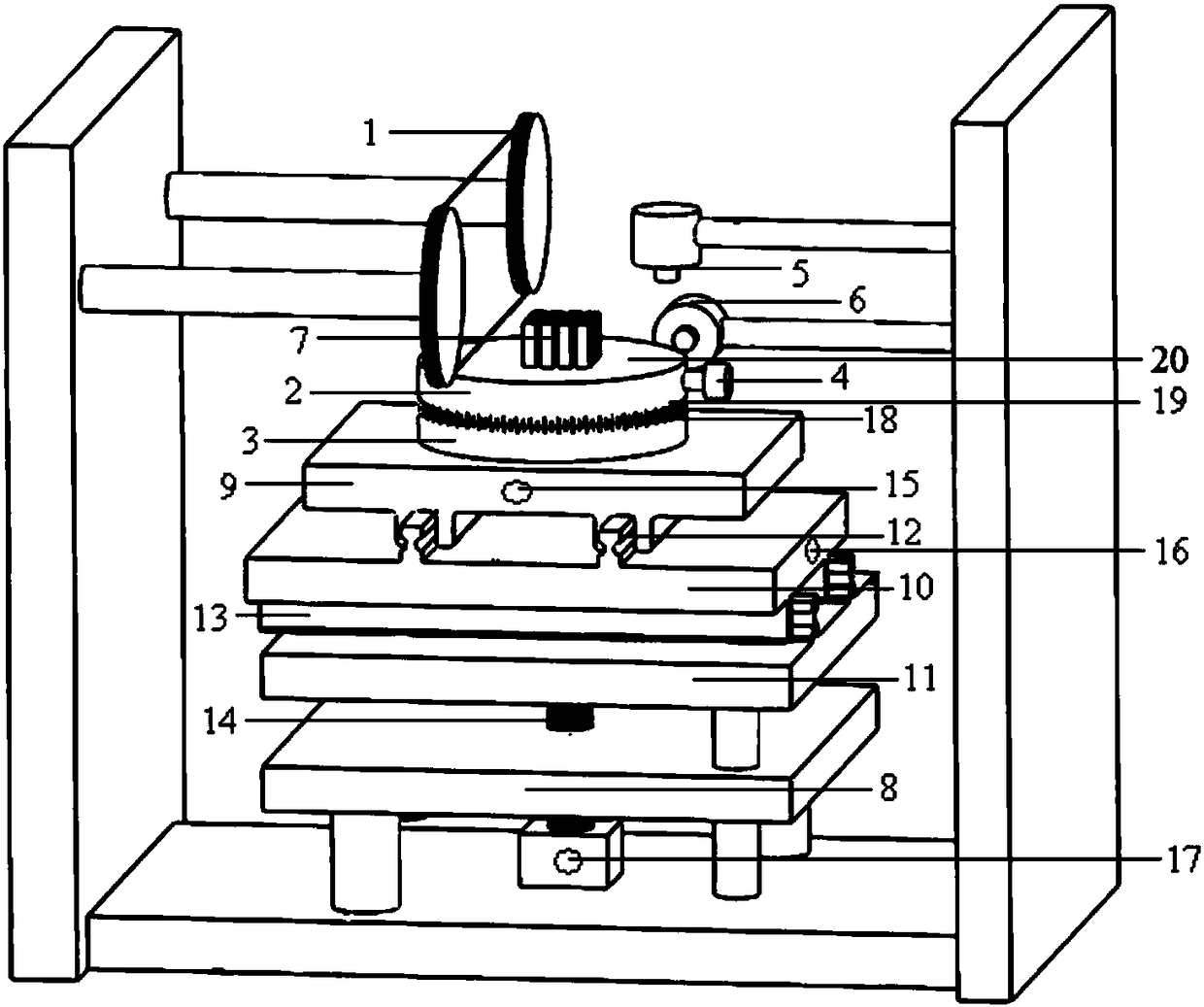

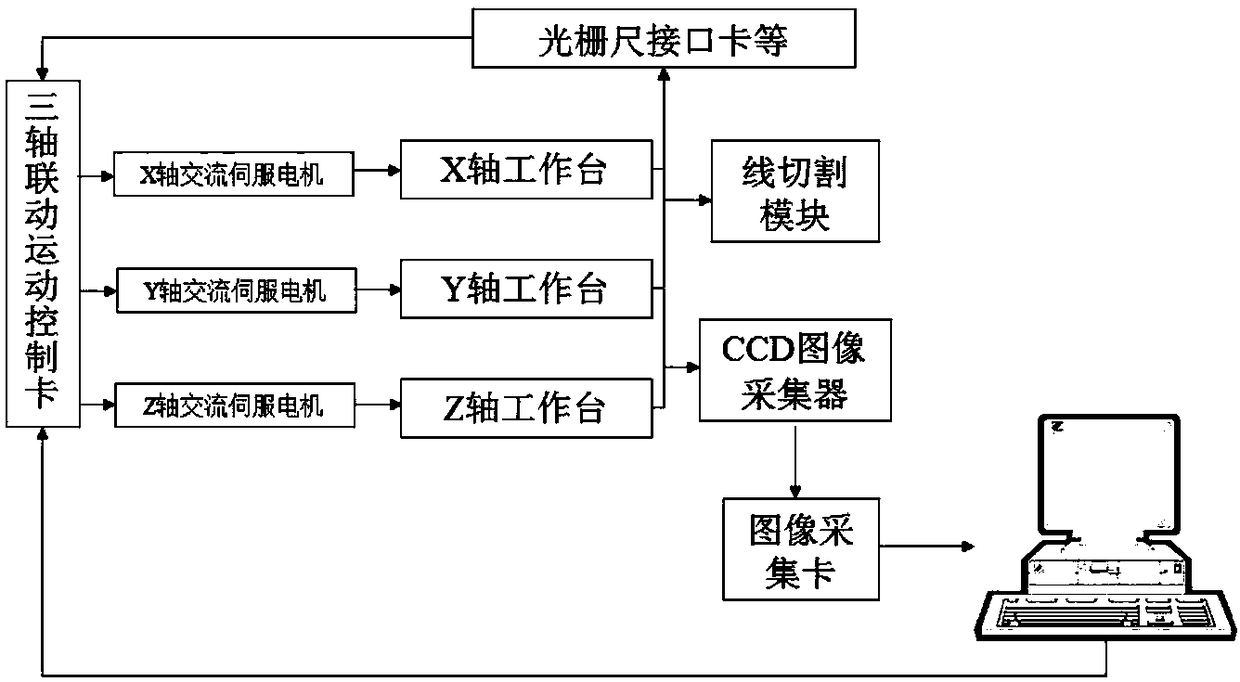

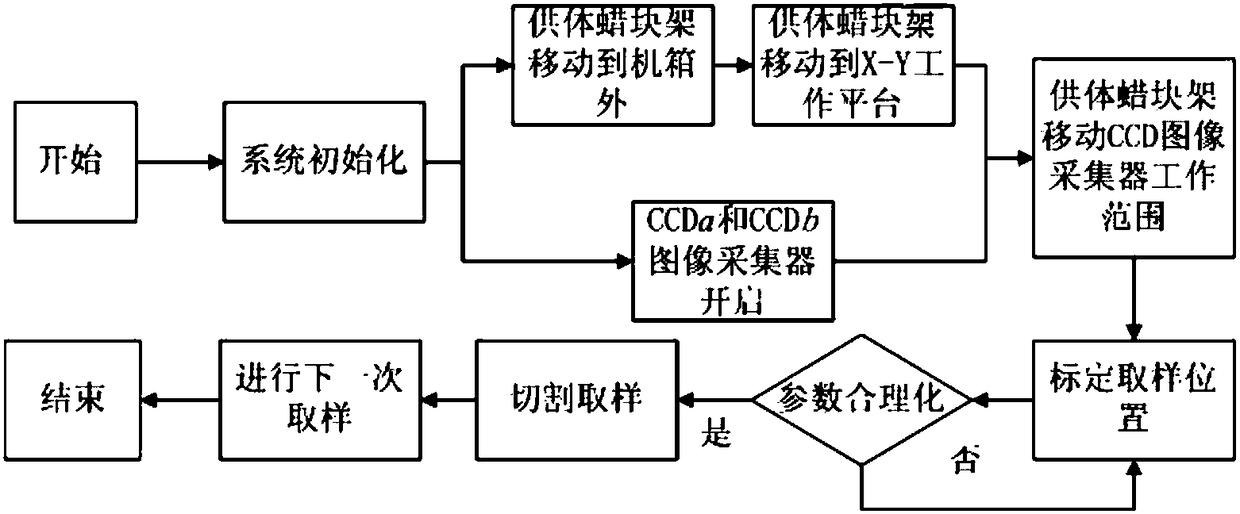

[0063] The main components of the core system involved in the present invention include a cutting system and a computer control system; the cutting system is as figure 1 shown. The cutting system includes a numerical control cutting machine, an XYZ axis translation workbench, a 360-degree rotating turntable, a recipient wax block rack 7, a freezing table 20 and an image recognition positioning module; the numerical control cutting machine includes a cutting machine workbench 8 and Cutter 1, an XYZ-axis translation workbench is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com