Soap and preparation method thereof

A soap and soap-based technology, applied in the field of daily chemicals, can solve problems such as difficult industrial production, and achieve the effects of high quality, reduced processing costs, environmental pollution and disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: This embodiment provides a preparation method of soap. The main components of the soap prepared by this preparation method include soap base, glycerin and plant additives. The plant additives include coffee grounds, soybean meal, wine meal, grape seed or A type of sunflower seed. For ease of illustration, the plant additive in this embodiment is coffee grounds. In the soap in this embodiment, the proportion of the plant additives is 6-40% of the weight of the soap, and it is optimal when the proportion of the plant additives is 10-30%, because the moisturizing quality of the soap is optimal. .

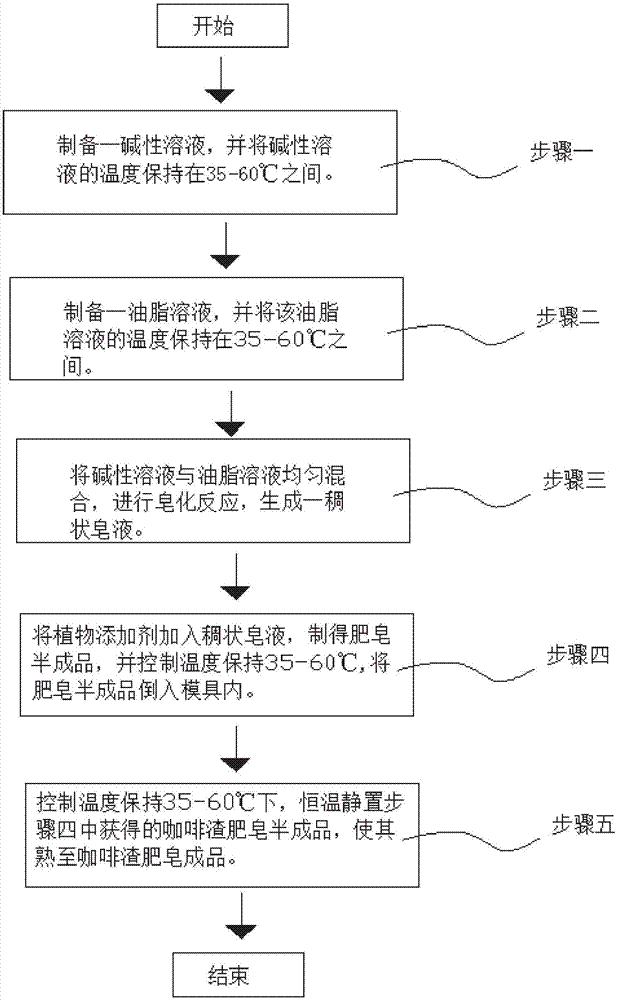

[0038] Please refer to figure 1 , the preparation method of soap provided in the present embodiment is a kind of method utilizing low-temperature wet method to manufacture soap, and it comprises the following steps:

[0039] Step 1: prepare alkaline solution;

[0040] Step 2: preparing a grease solution;

[0041] Step 3: uniformly mixing the alkaline solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com