A kind of carbon quantum dot fluorescent labeling material and preparation method thereof

A carbon quantum dot and fluorescent labeling technology is applied in the field of carbon quantum dot fluorescent labeling material and its preparation, which can solve the problems of difficult separation, complicated operation and high reaction temperature, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

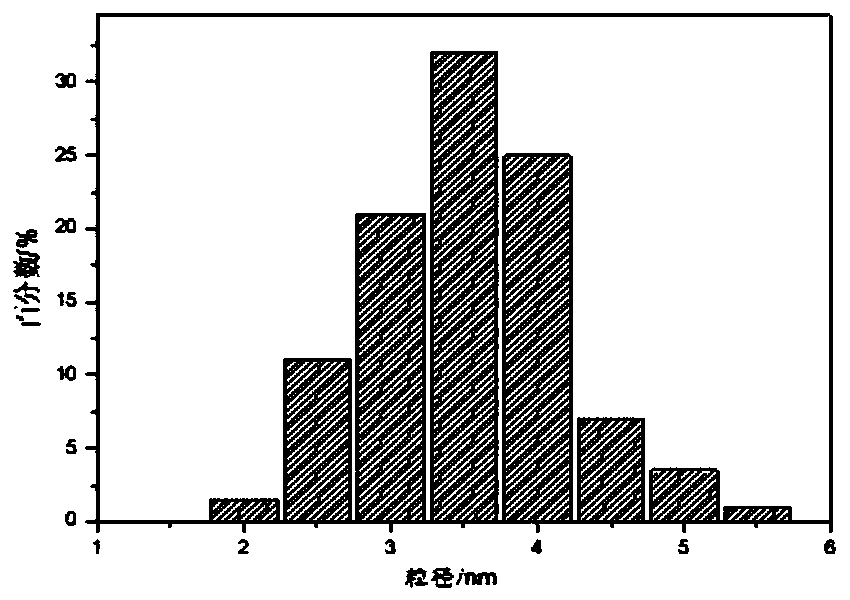

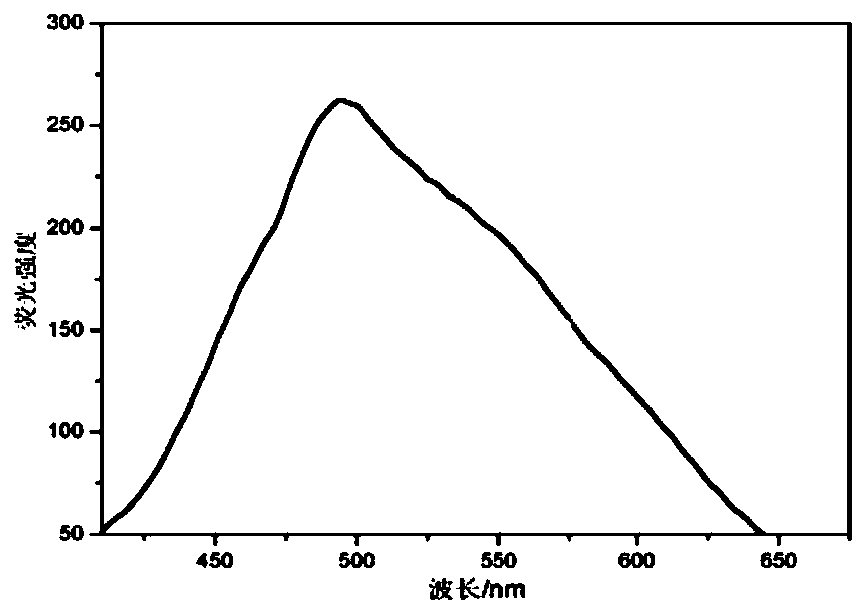

Image

Examples

Embodiment 1

[0034] A carbon quantum dot fluorescent labeling material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0035] (1) According to coal-based pyrolysis carbon: concentrated HNO 3 The mass ratio is 1: (10~16), the coal-based pyrolytic carbon is placed in the reactor first, and then the concentrated HNO 3 Add it into the reaction kettle, stir and reflux at 90-100°C for 4-5 hours, cool to room temperature, and take it out to obtain a black liquid.

[0036] (2) Filter the black liquid with a filter membrane with a pore size of 0.22 μm to obtain a filtrate; add NaOH solution to the filtrate to adjust the pH value to 5-6 to obtain a brown-black liquid.

[0037] (3) According to the brown-black liquid: the volume ratio of absolute ethanol is 1: (3~4), add absolute ethanol to the brown-black liquid, ultrasonically oscillate for 4~5 hours; centrifuge for 30 minutes, Obtain the supernatant and sink, remove the supernatant, the ...

Embodiment 2

[0040] A carbon quantum dot fluorescent labeling material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0041] (1) According to coal-based pyrolysis carbon: concentrated HNO 3The mass ratio is 1: (13~19), the coal-based pyrolytic carbon is placed in the reactor first, and then the concentrated HNO 3 Add it into the reaction kettle, stir and reflux at 95-105°C for 3-4 hours, cool to room temperature, and take it out to obtain a black liquid.

[0042] (2) Filtrate the black liquid with a filter membrane with a pore size of 0.22 μm to obtain a filtrate; add NaOH solution to the filtrate to adjust the pH value to 6-7 to obtain a brown-black liquid.

[0043] (3) According to the brown-black liquid: the volume ratio of absolute ethanol is 1: (3~4), add absolute ethanol to the brown-black liquid, ultrasonically oscillate for 4~5 hours; centrifuge for 30 minutes, Obtain the supernatant and sink, remove the supernatant, the...

Embodiment 3

[0046] A carbon quantum dot fluorescent labeling material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0047] (1) According to coal-based pyrolysis carbon: concentrated HNO 3 The mass ratio of the carbon is 1: (16-22), the coal-based pyrolytic carbon is placed in the reactor first, and then the concentrated HNO 3 Add it into the reaction kettle, stir and reflux at 100-110° C. for 3-4 hours, cool to room temperature, and take it out to obtain a black liquid.

[0048] (2) Filter the black liquid with a filter membrane with a pore size of 0.22 μm to obtain a filtrate; add NaOH solution to the filtrate to adjust the pH value to 7-8 to obtain a brown-black liquid.

[0049] (3) According to the brown-black liquid: the volume ratio of absolute ethanol is 1: (4~5), add absolute ethanol to the brown-black liquid, ultrasonically oscillate for 4~5 hours; centrifuge for 30 minutes in a centrifuge, Obtain the supernatant and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com