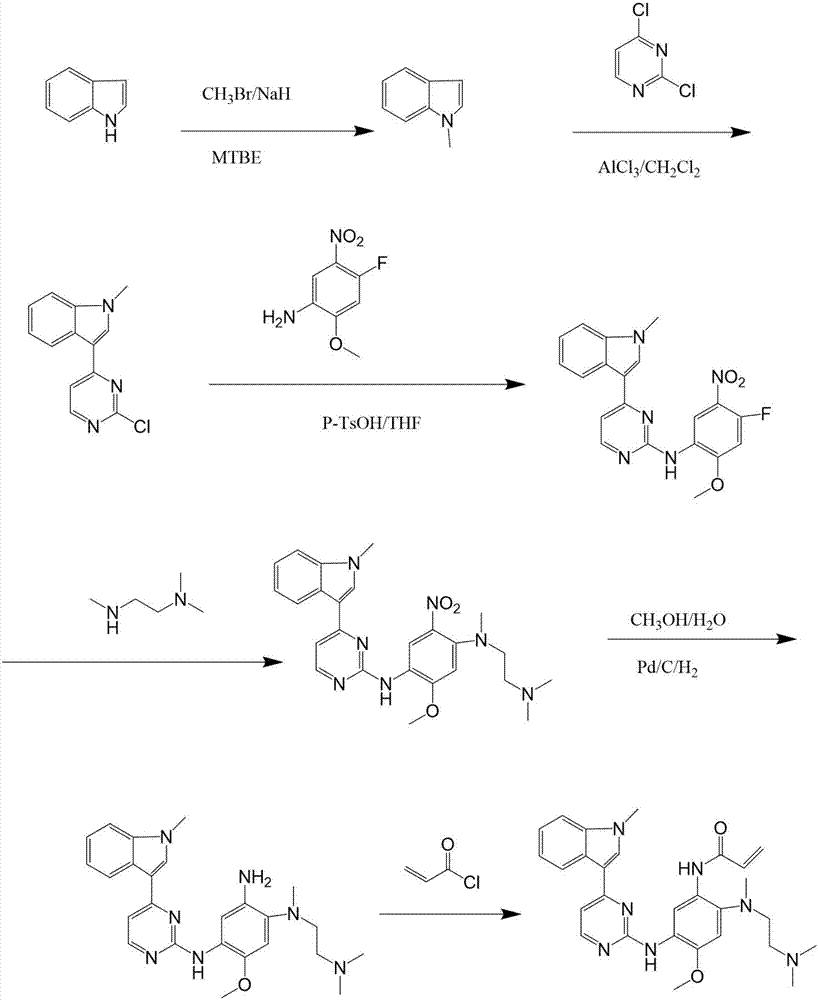

Preparation method of osimertinib

An intermediate, nitroanisole technology, applied in the field of organic synthesis technology medicinal chemistry, can solve problems such as being unsuitable for scale-up production, high equipment requirements, very low temperature, etc., and achieves mild reaction conditions, safe operation, and easy post-processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Intermediate 1

[0022] Weigh 50g of 5-fluoro-2-nitroanisole into a three-necked flask equipped with a thermometer, add 300ml of DMF, raise the temperature to 85°C, stir for 10min, add dropwise N,N,N'-trimethylethylenediamine 31.4 g. Stir for 4h. After the reaction was complete, 600ml of water was added dropwise. After stirring for 3 h, intermediate 1 was obtained as a yellow solid by filtration, with a yield of 90%.

[0023] Preparation of intermediate 2

[0024] Weigh 50g of intermediate 1, weigh 1.0g of Pd / C, add 250ml of methanol into a three-necked flask, and inject H 2 Keep 0.02MPa and react at 35°C for 5h. After the reaction was completed, Pd / C was filtered out, and the feed solution was concentrated to obtain a white solid with a yield of 85%.

[0025] Preparation of intermediate 3

[0026] Weigh 50g of intermediate 2, put it in a three-neck flask with 250ml of methanol, stir evenly, cool down to -10°C, add HNO dropwise 3 The amount was 14...

Embodiment 2

[0036]Preparation of Intermediate 1

[0037] Weigh 50g of 5-fluoro-2-nitroanisole into a three-necked flask equipped with a thermometer, add 300ml of DMF, raise the temperature to 85°C, stir for 20min, add dropwise N,N,N'-trimethylethylenediamine 32.8 g. Stir for 5h. After the reaction was complete, 600ml of water was added dropwise. After stirring for 3 h, the intermediate 1 was obtained as a yellow solid by filtration, with a yield of 95%.

[0038] Preparation of Intermediate 2

[0039] Weigh 50g of intermediate 1, weigh 0.5g~1.0g of RancyNi, add 250ml of methanol into a three-necked flask, and pour in H 2 Keep 0.02MPa and react at 35°C for 5h. After the reaction was completed, RancyNi was filtered out, and the feed liquid was concentrated to obtain a white solid with a yield of 70%.

[0040] Preparation of Intermediate 3

[0041] Weigh intermediate 2 as 50g, place 250mlH 2 SO 4 In a three-neck flask, stir evenly, cool down to -10°C, add HNO dropwise 3 The amount w...

Embodiment 3

[0051] Preparation of Intermediate 1

[0052] Weigh 50g of 5-fluoro-2-nitroanisole into a three-necked flask equipped with a thermometer, add 250ml of DMF, raise the temperature to 85°C, stir for 20min, add dropwise N,N,N'-trimethylethylenediamine 32.8 g. Stir for 5h. After the reaction was complete, 600ml of water was added dropwise. After stirring for 3 h, the intermediate 1 was obtained as a yellow solid by filtration, with a yield of 95%.

[0053] Preparation of Intermediate 2

[0054] Weigh 50g of intermediate 1, add 250ml of methanol and 100ml of water into a three-neck flask, stir, and add 25g of NH 4 Cl was reacted at 80°C for 6h. Fe powder was filtered out after the reaction was completed, and the feed solution was concentrated to obtain a white solid with a yield of 70%.

[0055] Preparation of Intermediate 3

[0056] Weigh intermediate 2 as 50g, place 250mlH 2 SO 4 In a three-neck flask, stir evenly, cool down to -10°C, weigh KNO 3 The amount is 26.0g, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com