Magnesium oxysulfate-based inorganic composite gelling material with high flexural strength

A technology of cementitious material and inorganic composite, which is applied in the field of high flexural magnesium oxysulfoxide-based inorganic composite cementitious materials, can solve limited problems, and achieves improved flexural strength and compressive strength, improved water resistance, and improved compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

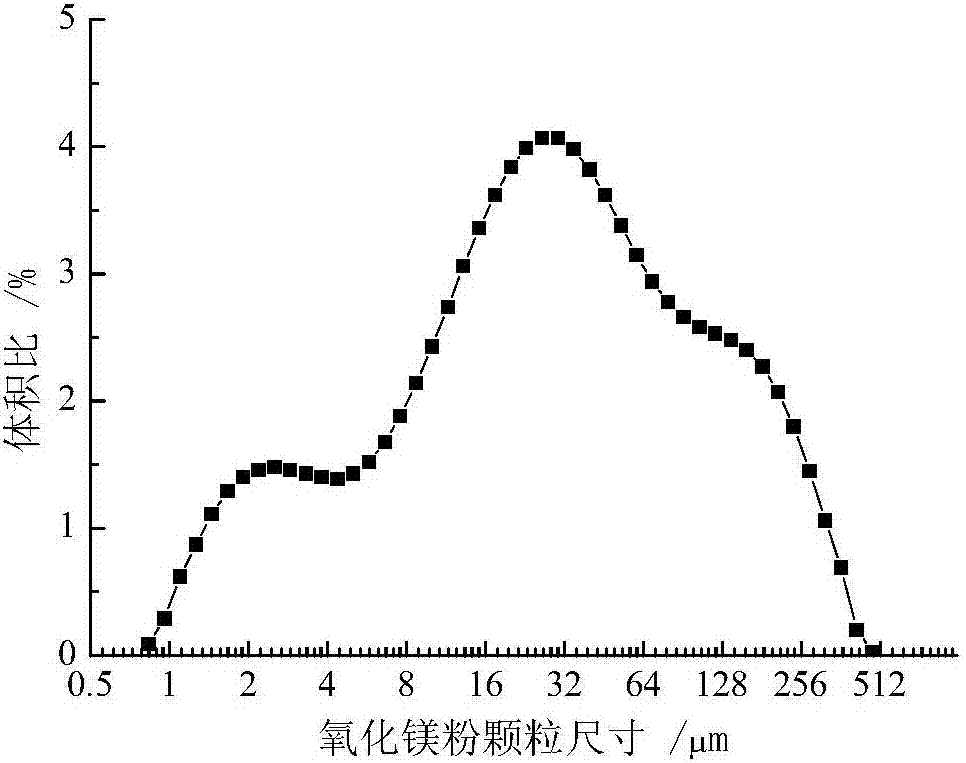

[0029] The high anti-folding magnesium oxysulfide-based inorganic composite gelling material of embodiment 1, by weight, the composition of the gelling material is: 352 parts of lightly burned magnesium oxide powder, 154 parts of magnesium sulfate heptahydrate, 1.9 parts of citric acid And 19 parts of silica fume.

Embodiment 2

[0030] The high anti-folding magnesium oxysulfide-based inorganic composite gelling material of embodiment 2, by weight, the composition of the gelling material is: 334 parts of lightly burned magnesium oxide powder, 146 parts of magnesium sulfate heptahydrate, 1.9 parts of citric acid And 37 parts of silica fume.

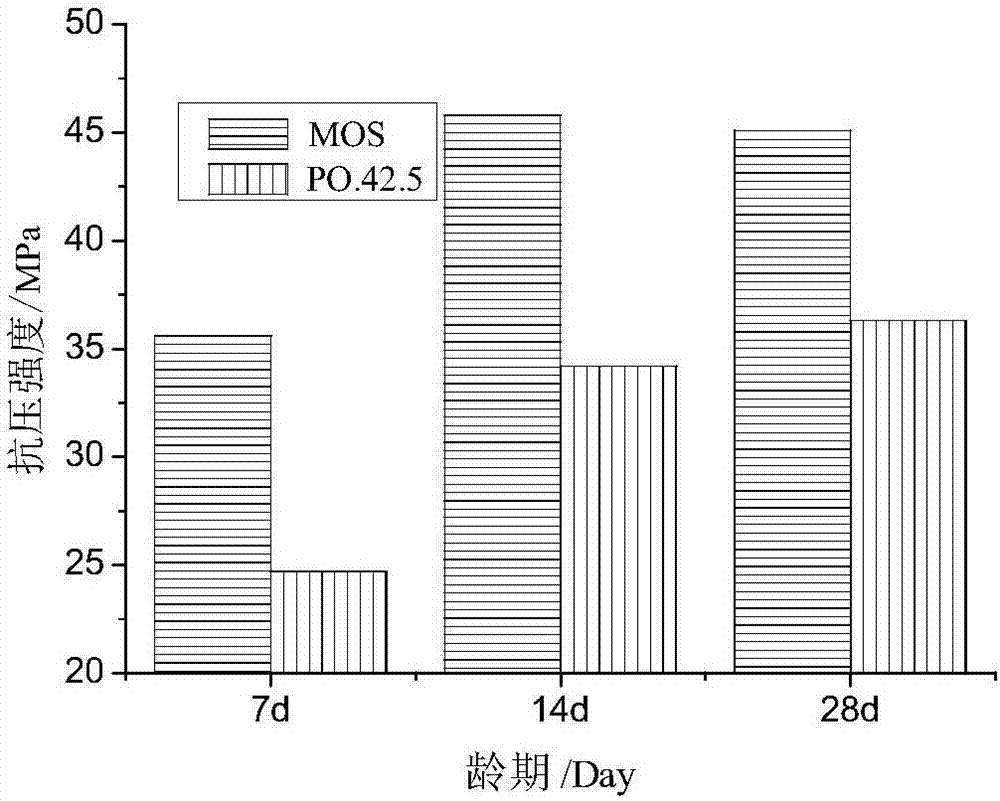

[0031] According to the national standard GB175-2007 "Universal Portland Cement" and GB17671-1999 "Cement Mortar Strength Test Method", cement, standard sand and water are formulated into mortar according to the specified ratio (1:3:0.5), and made The 40mm×40mm×160mm specimens were removed from the mold and cured to a certain age (3d and 28d) under standard curing conditions to measure their compressive strength and flexural strength. The determination of compressive strength and flexural strength was compared with ordinary Portland cement. Due to MgSO 4 ·7H 2 O contains water, so it is necessary to adjust the quality of light-burned magnesia powder, magnesium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com