Nail type middle rapid energy-saving conductive contact

A technology of conductive joints and conductive heads, which is applied in the direction of conductive connections, circuits, connections, etc., can solve the problems of difficult to disassemble wires, complicated installation, easy breakage, etc., and achieve the effects of reducing power loss, simple and reasonable structure, and improving conductive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

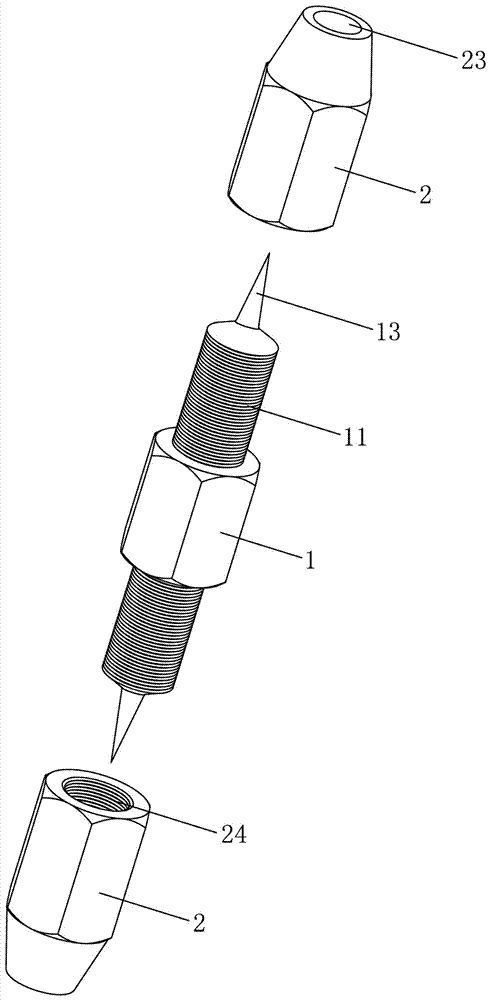

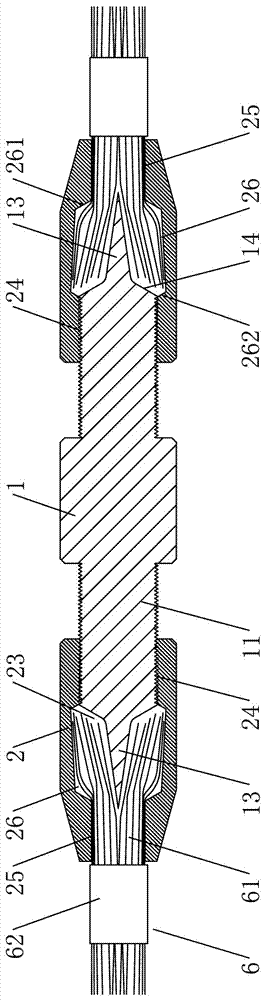

[0023] see figure 1 and figure 2 As shown, a nail-type intermediate fast energy-saving conductive joint includes an intermediate conductive head 1, and the intermediate conductive head 1 is provided with two externally threaded ends 11, and the end surface of the externally threaded end 11 is provided with a splitting pointed nail 13, The outer threaded end 11 is externally threaded with an outer lock nut 2, and the outer lock nut 2 is provided with a sleeve hole 23 passing through both ends thereof, and the diameter of the outer port of the sleeve hole 23 is smaller than the diameter of the middle section and the rear end.

[0024] The end surface of the external thread end 11 is provided with a branching pointed nail 13, the branching pointed nail 13 is positioned at the center of the external thread terminal 11 end faces, the branching pointed nail 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com