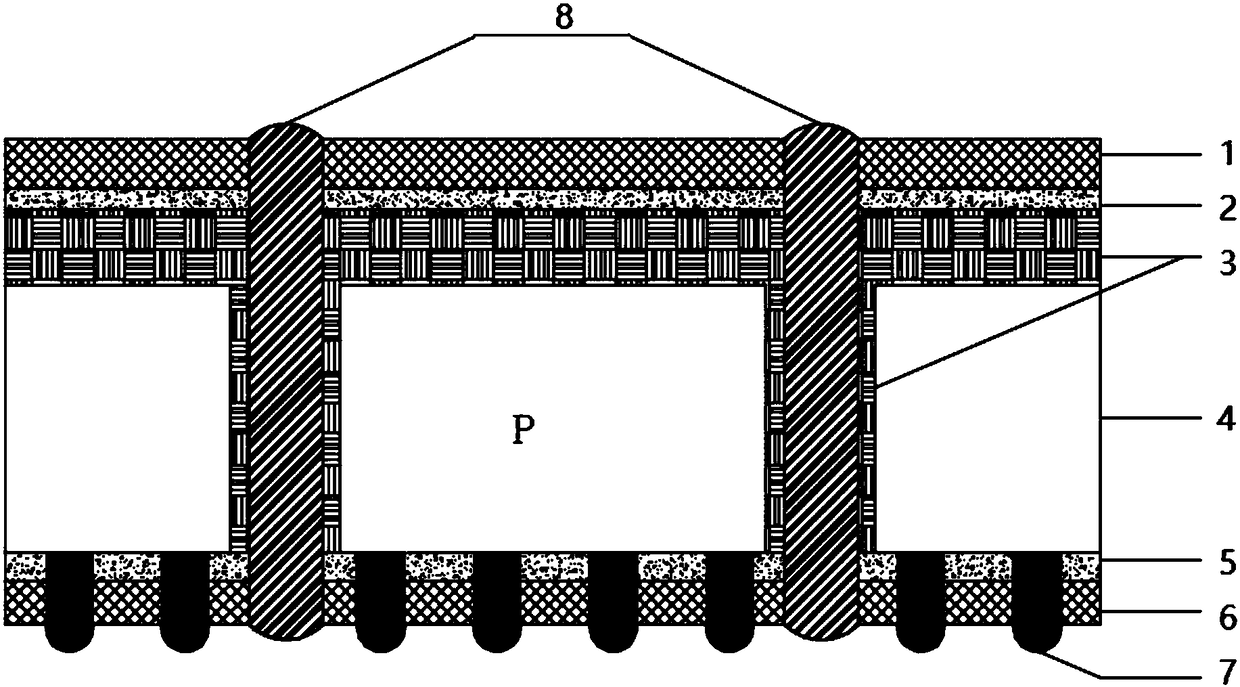

String connection structure, component and method of p-type crystalline silicon back-contact bifacial battery

A double-sided cell and connection structure technology, applied in the field of solar cells, can solve problems such as process requirements, high production costs, and poor compatibility, and achieve the effects of reducing light-shielding area, reducing production costs, and improving the front

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

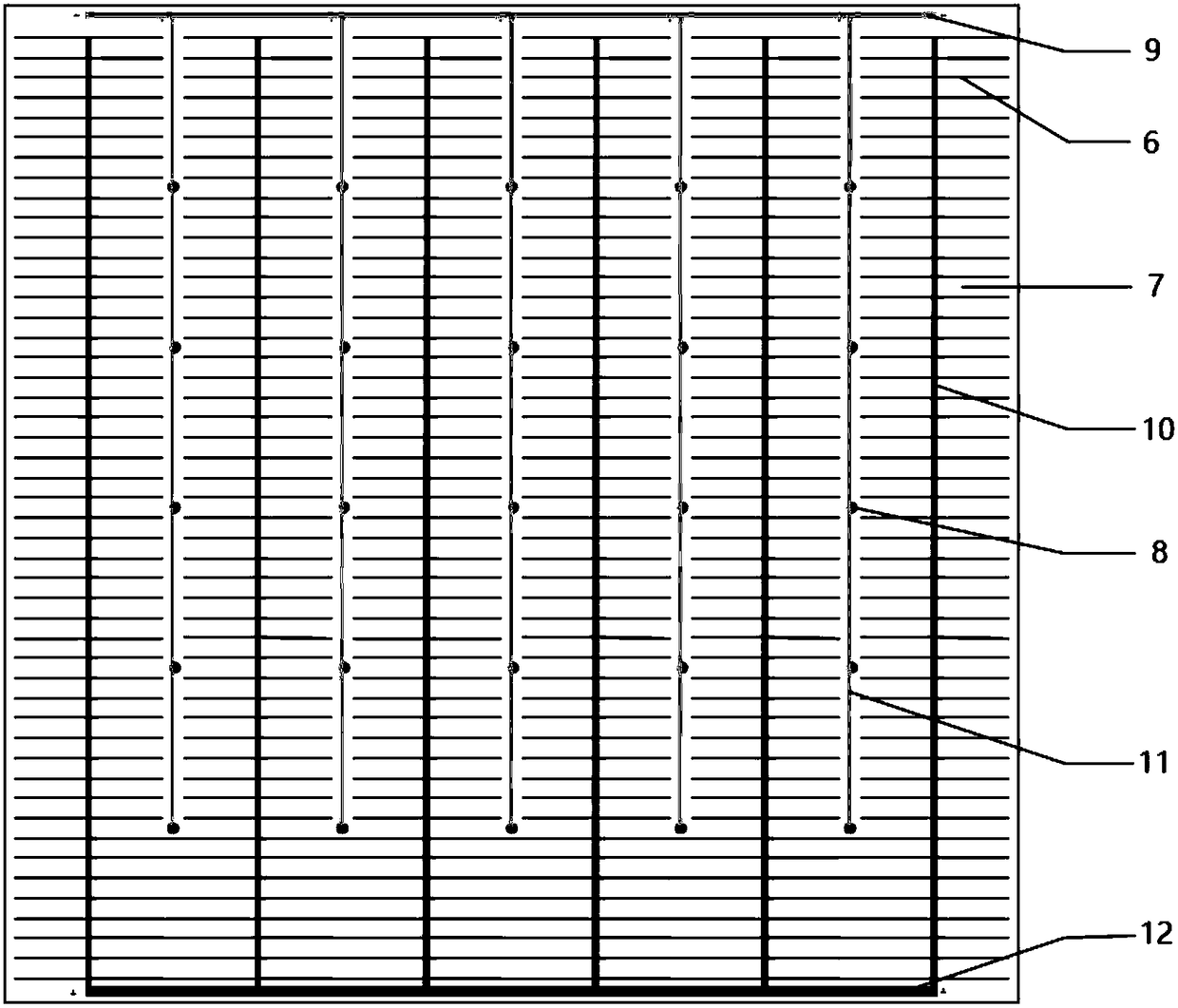

Embodiment 1

[0051] (1) Make a positive electrode reflective ribbon with a width of 1.5mm on the positive silver busbar on the back of the entire P-type monocrystalline silicon back-contact double-sided battery; make a negative electrode with a width of 1.5mm on each row of via-hole silver electrodes Reflective ribbon. The positive and negative reflective ribbons of adjacent battery slices are connected to connect the battery slices into a battery string.

[0052] (2) Laminate in the order of ultra-clear tempered glass, EVA, battery string, EVA, and ultra-clear tempered glass.

[0053] (3) Laminate the stack formed in step (2) in a laminator to cross-link the EVA, and combine the battery string and the ultra-clear tempered glass on the front and back as a whole.

[0054] (4) After processing such as trimming, framing, and junction box installation, a photovoltaic module that can be used for double-sided power generation is formed.

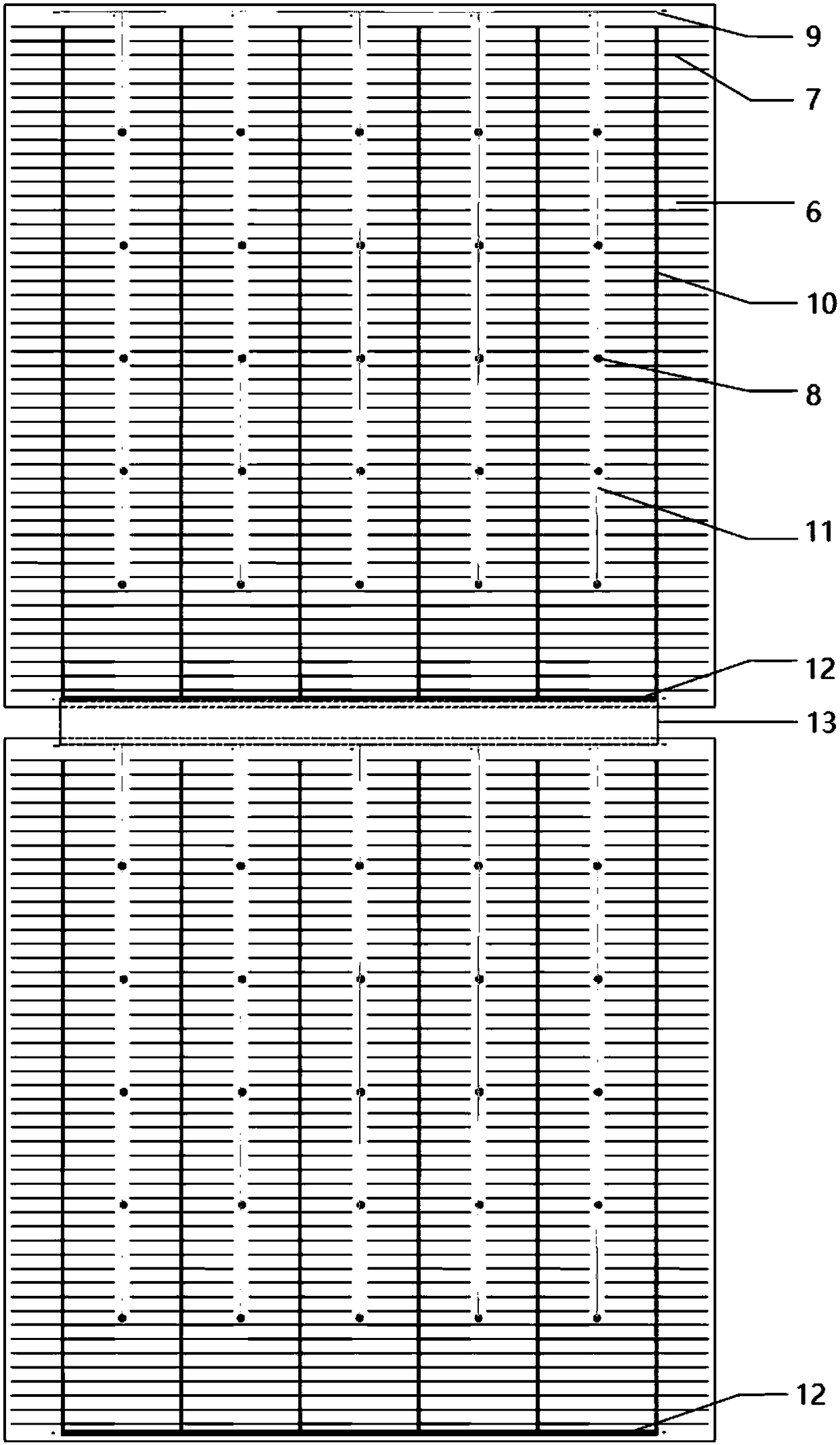

Embodiment 2

[0056] (1) During the electrode manufacturing process of the battery sheet, a 2mm-wide positive extension structure is provided for the positive busbar on the back side. The hole electrodes are connected by silver grid lines, and form a negative electrode extension structure with a width of 2 mm on the other side of the edge of the silicon wafer, and the extension structure vertically intersects with the silver grid lines on the via hole electrodes. The positive and negative electrode extension structures are oppositely arranged on the back of the battery.

[0057] (2) Coating solder paste on the positive and negative extension structures of the battery, and combining the positive and negative extension structures of adjacent batteries through a 3mm wide copper strip to form a battery string.

[0058] (3) Laminate in the order of ultra-clear tempered glass, PVB, battery string, PVB, and ultra-clear tempered glass.

[0059] (4) Laminate the stack formed in step (2) in a lamina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com