Preparation method for carbon nanotube-based conductive cotton fabric

A carbon nanotube and conductive cotton technology, which is applied in the field of preparation of conductive cotton fabrics, can solve the problems of low efficiency, cumbersome operation, low carbon nanotube loading, etc., and achieves the effects of simplified process, good conductivity and soft quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

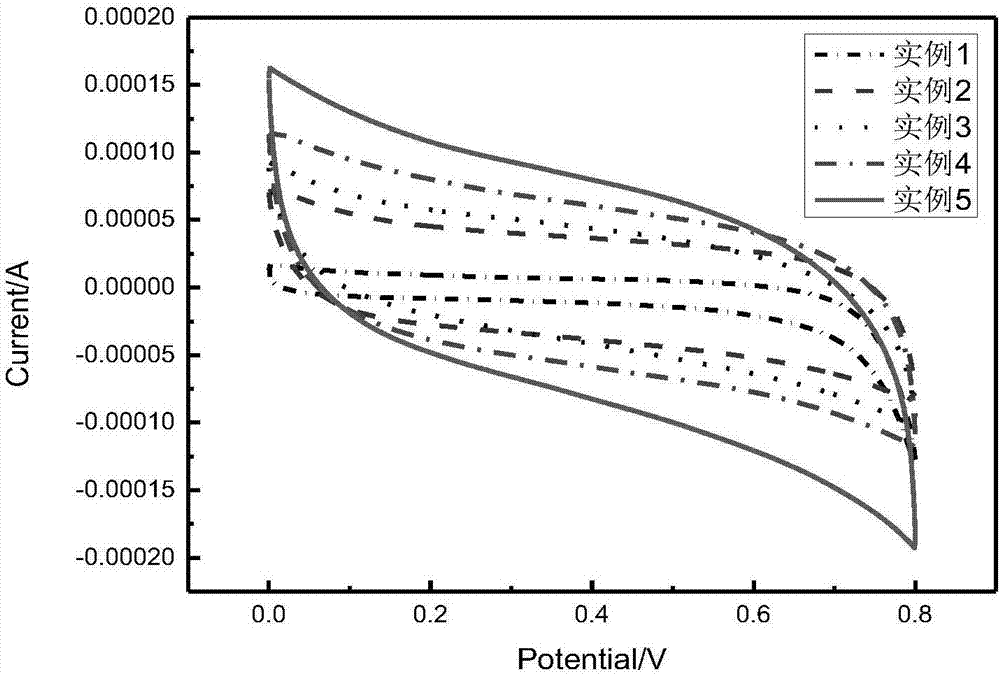

Embodiment 1

[0020] (1) Preparation of carbon nanotube solution:

[0021] Carboxylated carbon nanotubes and aminated carbon nanotubes were mixed, added to 35ml deionized water, then sodium dodecylbenzenesulfonate was added (the total mass ratio of carbon nanotubes was 1:1), stirred, and then used A homogenizer is used to disperse to obtain a carbon nanotube dispersion.

[0022] (2) Preparation of conductive cotton fabric:

[0023] Put the cotton fabric and the above-mentioned carbon nanotube dispersion in an infrared proofer for treatment. The treatment condition is to raise the temperature from 5°C / min to 135°C for 70 minutes; then take it out and dry it in an oven at 100°C; finally wash it with water and dry it at room temperature Dry; wherein, the mass ratio of cotton fabric, carboxylated carbon nanotubes and aminated carbon nanotubes is 1:0.3:0.03.

Embodiment 2

[0025] (1) Preparation of carbon nanotube solution:

[0026] Carboxylated carbon nanotubes and aminated carbon nanotubes were mixed, added to 35ml deionized water, then sodium dodecylbenzenesulfonate was added (the total mass ratio of carbon nanotubes was 1:1), stirred, and then used A homogenizer is used to disperse to obtain a carbon nanotube dispersion.

[0027] (2) Preparation of conductive cotton fabric:

[0028] Put the cotton fabric and the above-mentioned carbon nanotube dispersion in an infrared proofer for treatment. The treatment condition is to raise the temperature from 5°C / min to 135°C for 70 minutes; then take it out and dry it in an oven at 100°C; finally wash it with water and dry it at room temperature Dry; wherein, the mass ratio of cotton fabric, carboxylated carbon nanotubes and aminated carbon nanotubes is 1:0.3:0.06.

Embodiment 3

[0030] (1) Preparation of carbon nanotube solution:

[0031] Carboxylated carbon nanotubes and aminated carbon nanotubes were mixed, added to 35ml deionized water, then sodium dodecylbenzenesulfonate was added (the total mass ratio of carbon nanotubes was 1:1), stirred, and then used A homogenizer is used to disperse to obtain a carbon nanotube dispersion.

[0032] (2) Preparation of conductive cotton fabric:

[0033] Put the cotton fabric and the above-mentioned carbon nanotube dispersion in an infrared proofer for treatment. The treatment condition is to raise the temperature from 5°C / min to 135°C for 70 minutes; then take it out and dry it in an oven at 100°C; finally wash it with water and dry it at room temperature Dry; wherein, the mass ratio of cotton fabric, carboxylated carbon nanotubes and aminated carbon nanotubes is 1:0.3:0.09.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com