Screening method of total lead content in textile

A screening method and lead content technology, applied in the preparation of test samples, measuring devices, material analysis through observation of the impact on chemical indicators, etc., can solve problems such as few reports, achieve short detection time and save costs , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

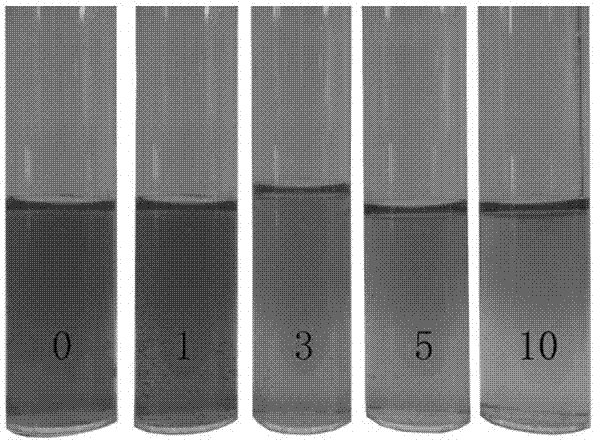

[0052] Comparative example 1——color development object of lead solution

[0053] Weigh 5 parts of 0.5g coating, cut into pieces; add 5ml concentrated nitric acid and 1ml hydrogen peroxide to each coating, then add 0μL, 10μL, 30μL, 50μL, 100μL lead standard solution (1000ppm ), after wet digestion at 160°C for 50min, cool to room temperature; filter to remove the digested residue in the solution, then add 3mL concentrated sodium hydroxide solution to the filtrate; adjust the pH value of the filtrate with dilute nitric acid and sodium hydroxide solution is about 3.0-4.5, then add 0.5mL ascorbic acid solution, 1mL potassium iodide solution and 0.4mL malachite green solution to the filtrate, set the volume to 10mL, and mix well to prepare the color-developed object of the lead solution (see figure 1 shown).

[0054] By Example 1 and figure 1 It can be seen that the corresponding textiles to which 0 μL, 10 μL, 30 μL, 50 μL and 100 μL of lead standard solution are added respective...

Embodiment 2

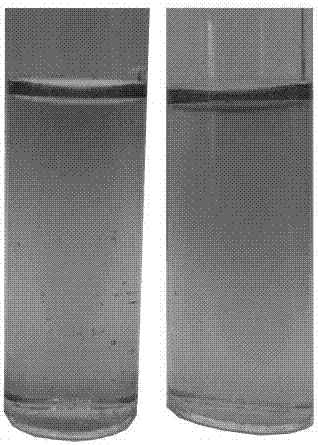

[0056] Weigh 2 parts of 0.5g of coatings with lead content not exceeding the standard and 2 parts of 0.5g of coatings with lead content exceeding the standard, and number them respectively as 1#, 2#, 3# and 4#, and cut each sample into pieces; Add 5mL concentrated nitric acid and 1mL hydrogen peroxide to each sample, after 160°C wet digestion for 50min, cool to room temperature; where:

[0057] Filter 1# and 3#, dilute to 50mL with deionized water, and then use inductively coupled plasma-atomic emission spectrometry to determine the total lead content in textiles;

[0058] Filter 2# and 4# to remove the digested residue in the solution, then add 3mL of concentrated sodium hydroxide solution to the filtrate, adjust the pH value of the filtrate to about 3.0-4.5 with dilute nitric acid and sodium hydroxide solution, and then add to the filtrate Add 0.5mL of ascorbic acid solution, 1mL of potassium iodide solution and 0.4mL of malachite green solution to the solution, and set the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com