Connection pair for lock nut with memory alloy ring

A technology of memory alloy and locking nuts, which is applied in the direction of nuts, connecting components, locking fasteners, etc., can solve the problems of difficult disassembly, poor corrosion resistance, and large tightening torque, so as to avoid safety accidents or economic losses, excellent Effect of damping and corrosion resistance, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

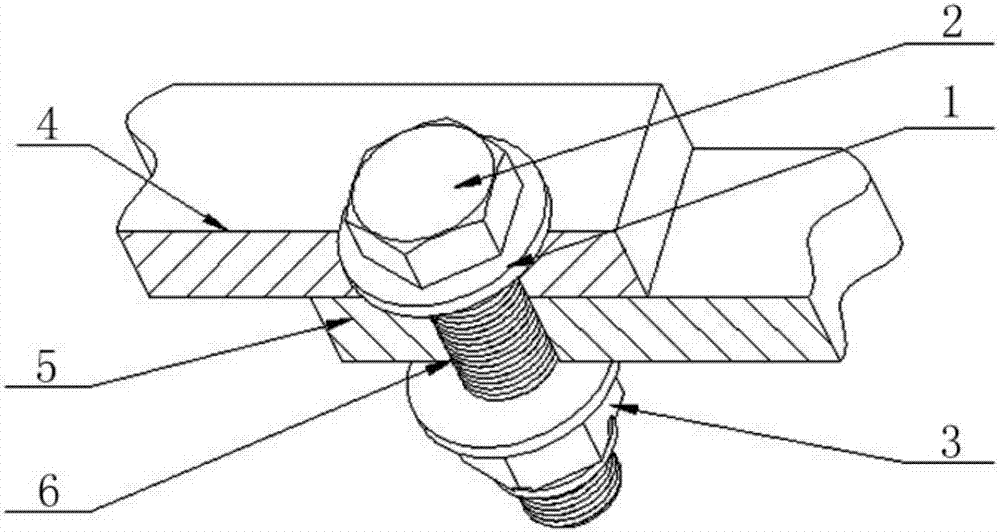

[0029] see figure 1 As shown, a connection pair with a lock nut with a memory alloy ring is used to lock the connected part, which includes a threaded locking part and a threaded locking part that is in contact with the surface of the connected part memory alloy spacer 1.

[0030] In this embodiment, the locking member includes a bolt 2 and a memory alloy lock nut 3 matched with the bolt 2 . The bolt 2 passes through the through hole 6 of the connected part 4 and the connected part 5, and the memory alloy lock nut 3 is screwed on the part where the bolt 2 protrudes from the connected part 4 and the connected part 5, and the bolt 2 and the connected part are screwed. A memory alloy gasket 1 is installed between the connecting parts 4 and between the memory alloy lock nut 3 and the connected part 5 .

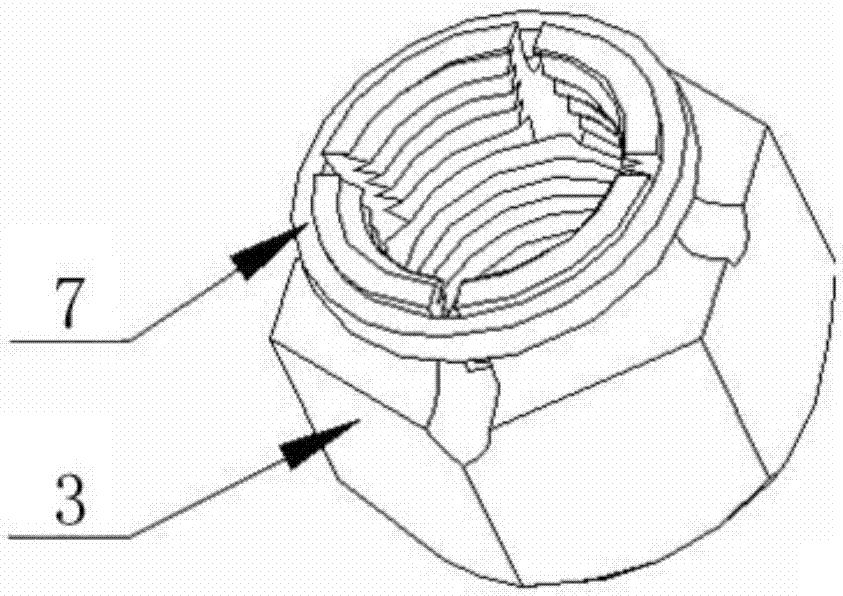

[0031] see figure 2 As shown, the memory alloy lock nut 3 is provided with a memory alloy ring 7. When the memory alloy lock nut 3 is tightened to the corresponding position o...

Embodiment 2

[0033] see image 3 As shown, a connection pair with a lock nut with a memory alloy ring is used to lock the connected part, which includes a threaded locking part and a threaded locking part that is in contact with the surface of the connected part memory alloy spacer 1.

[0034] In this embodiment, the locking member includes a stud 8 and a memory alloy lock nut 3 matched with the stud. The stud 8 passes through the through hole 6 of the connected part 4 and the connected part 5, and the memory alloy lock nut 3 is installed on the part where the stud 8 protrudes from the connected part 4 and the connected part 5, and the stud 8 A memory alloy gasket 1 is installed between the memory alloy gasket 1 and the connected part 4, and a buffer gasket 9 is installed between the memory alloy gasket 1 and the connected part 4. The buffer gasket is a common spring washer, a flat gasket, a metal winding Gaskets, embossed gaskets or toothed gaskets.

[0035] The memory alloy lock nut 3...

Embodiment 3

[0037] see Figure 4 As shown, a connection pair with a lock nut with a memory alloy ring is used to lock the connected part, which includes a threaded locking part and a threaded locking part that is in contact with the surface of the connected part memory alloy spacer 1.

[0038] In this embodiment, the locking member includes a bolt 2 . The bolt 2 passes through the through hole 6 of the connected part 4 and the connected part 5, and a memory alloy gasket 1 is installed between the bolt 2 and the connected part 4. The memory alloy gasket 1 provides lasting elastic force to ensure a firm connection lasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com