Double-hole-shaped segmented rotary powder charging solid-liquid rocket engine thrust chamber

A solid-liquid rocket and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as low combustion efficiency, poor mixing degree of oxidant and fuel, and low burning rate of solid fuel grains, and achieves improved Combustion efficiency, improvement of combustion efficiency, and high loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

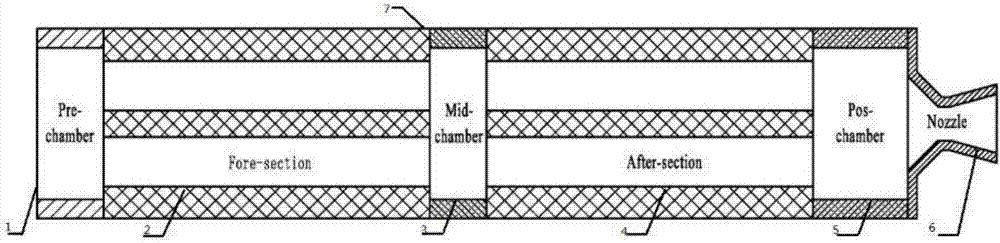

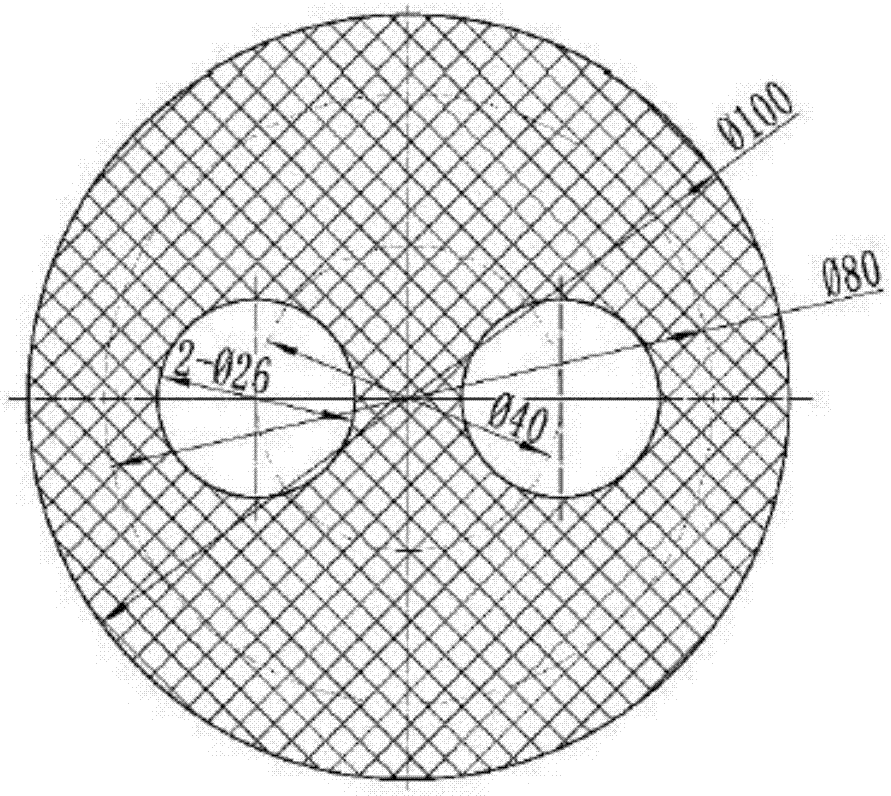

[0020] The present invention is a kind of thrust chamber of solid-liquid rocket engine of solid-liquid rocket engine of a kind of double-hole shape segmental rotation, such as figure 1 , figure 2 As shown, it includes a front combustion chamber assembly 1 , a front solid fuel grain column 2 , an intermediate cavity assembly 3 , a rear solid fuel grain column 4 , a rear combustion chamber assembly 5 , a nozzle assembly 6 , and a combustion chamber housing 7 .

[0021] The solid fuel grain is packed into the engine combustion chamber casing, and the outer wall surface of the intermediate cavity is bonded to the inner wall surface of the engine combustion chamber casing. The rear end of the engine nozzle assembly, the afterburner assembly and the combustion chamber shell is connected by long bolts, and an O-ring seal is used to ensure airtightness.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com