Waste rock and cementing layered wedge bonding filling mining technology and structure thereof

A backfill mining and cemented backfill technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of low labor productivity, ore block production capacity, unreasonable application of waste rock, troublesome surface storage, etc., so as to reduce the surface Storage and transportation costs, improving the utilization rate of waste rock, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

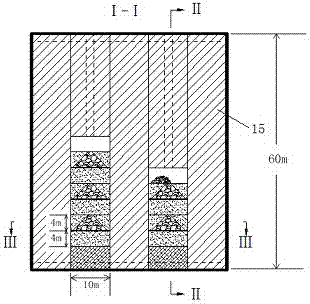

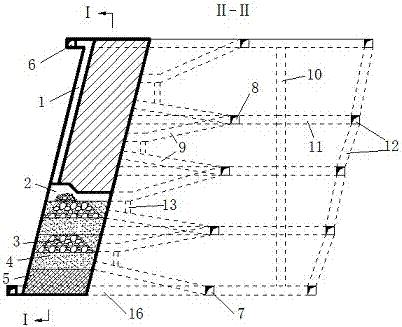

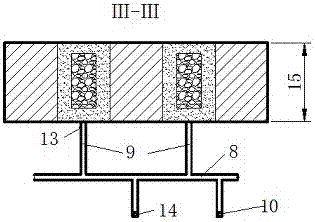

[0025] The specific use case of the mining scheme proposed by the present invention is: for the mining of the above-mentioned types of ore bodies, the stage height is 40-60m, and the length of the ore block is generally 50-60m, which can be reduced to 30-60m when the ore body is broken and the ground pressure is large. 40m. First pass through the middle section of the ore body floor and the ramp to excavate the mining area contact road, subsection entry, subsection exit entry, and slip shaft, and then excavate the return air filling shaft close to the ore body floor to communicate with the upper and middle section of the prospecting entry . Before mining, excavate the cutting horizontal roadway at the bottom of the ore block, excavate the cutting roadway along the ore body, and use the cutting horizontal roadway as the free surface to pull the bottom along the cutting roadway. The plastic bellows of the holes are connected to the small well for filling and drainage, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com