Thermal field structure for supersized silicon ingot

A super-sized silicon ingot technology, applied in the field of polysilicon production equipment, can solve problems such as the inability to effectively reduce crystal dislocations and impurities, unfavorable growth of super-large silicon ingots, and unsatisfactory temperature gradients, so as to improve process flexibility and save The effect of using cost and expanding the internal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

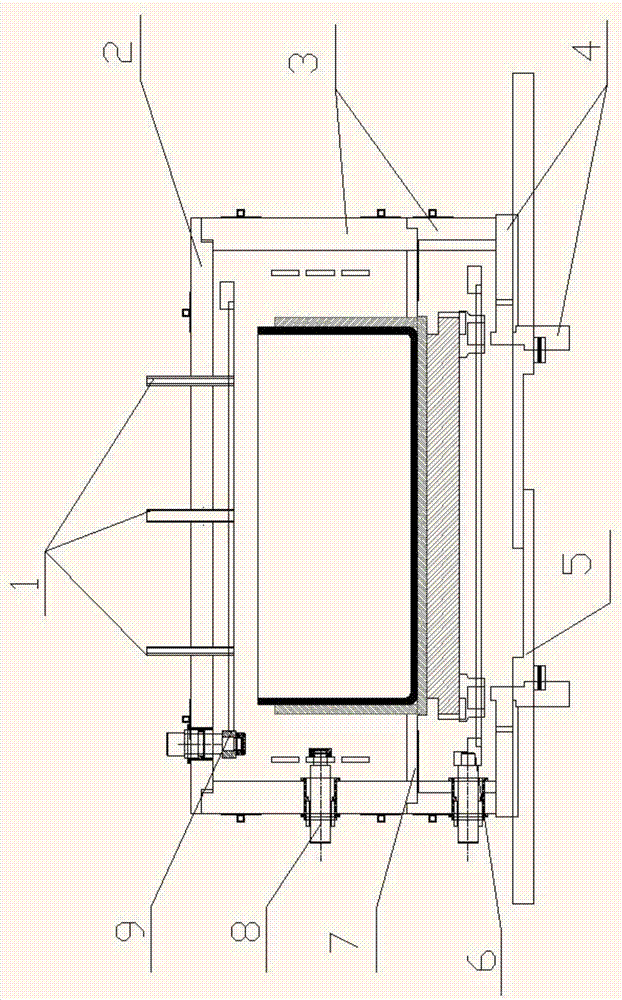

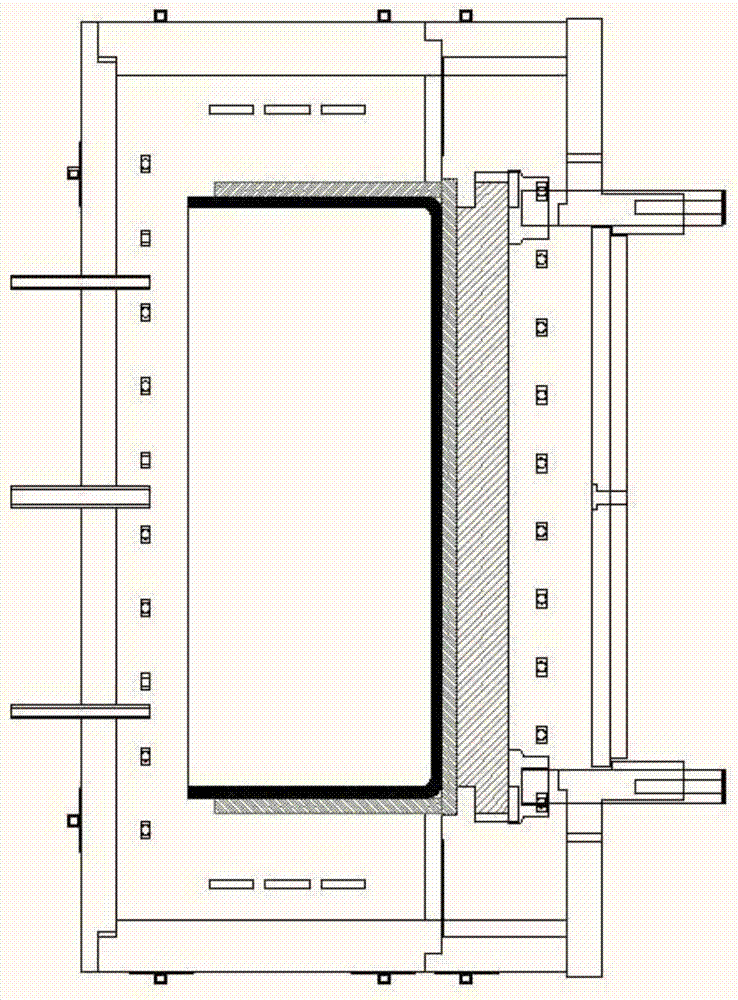

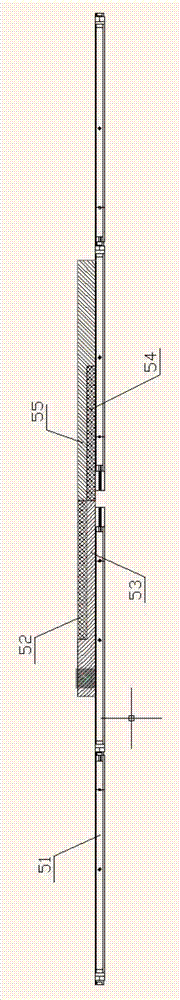

[0028] refer to figure 1 and figure 2 , a thermal field structure for super-sized silicon ingots, including a heat insulation cage surrounded by a top heat preservation component 2, a side heat preservation component 3 and a bottom heat preservation component 4. The size of the heat insulation cage is designed according to the size of the crucible. A heat exchange control device 5 is provided at the bottom of the heat-insulation cage, and a directional solidified block for placing a graphite crucible is arranged in the heat-insulated cage above the heat-exchange control device 5. The directional solidified block is used to support the crucible and is used for crystallization simultaneously. Heat exchange, can assist heat cond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap