Electrode for electrochemical reduction of carbon dioxide, preparation method and application thereof

A CO2, Electrochemical Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

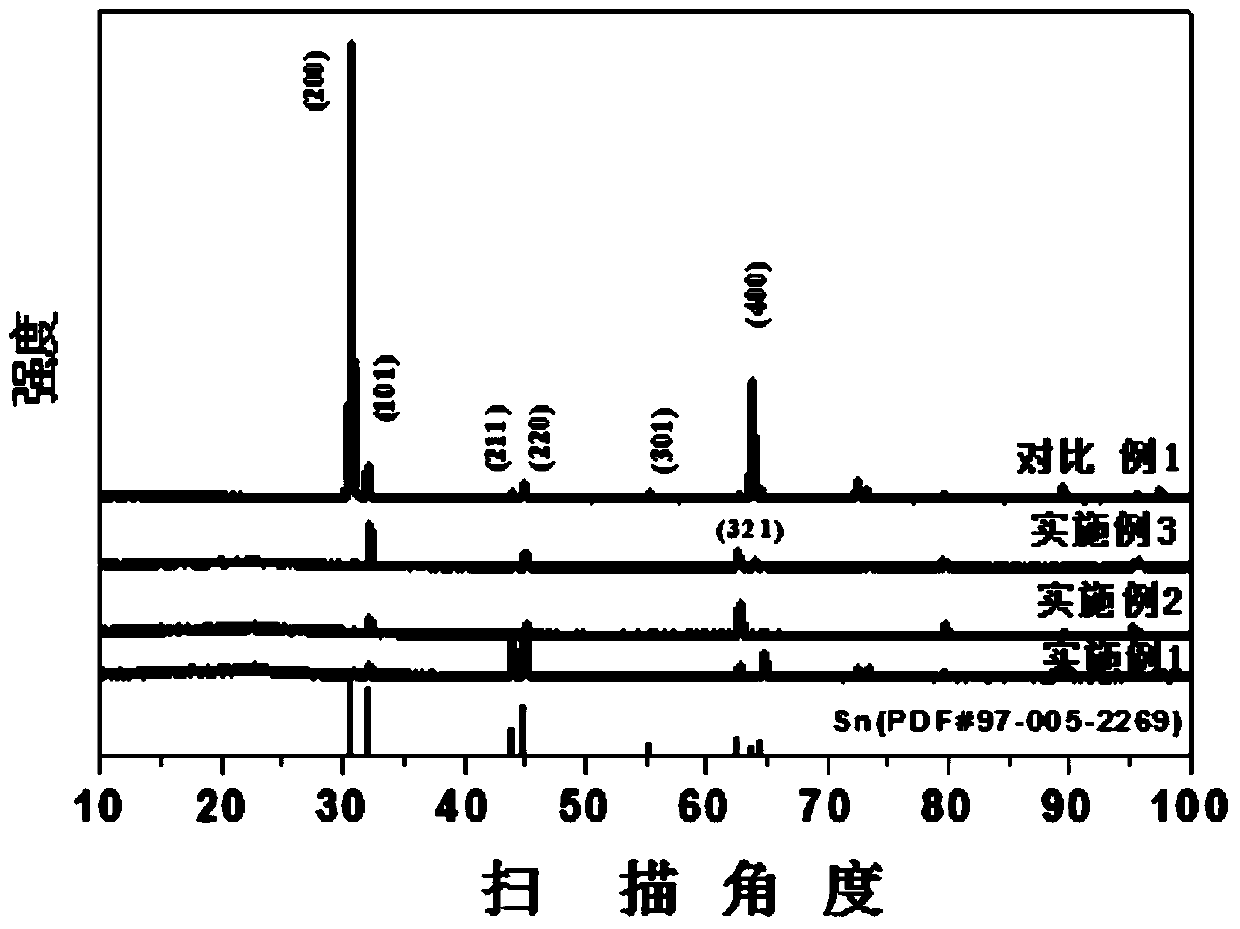

Embodiment 1

[0038] The carbon paper was treated in the air at 550°C, and then degreased and cleaned in ethanol and acetone as the substrate; the concentration was 0.25M SnSO 4 solution, with 0.7M H 2 SO 4 And the Trix100 of 0.06M, mix and obtain mixture solution as electrolyte solution; In electrolyte solution, in N 2 Constant current density-60mA cm was carried out under the protection of atmosphere -2 Constant potential deposition for 2000s; 0.5M NaHCO in post-treatment electrolyte 3 The electrolytic solution was reduced with -1.2V for 900s; the Sn nanorod catalyst was prepared after washing and drying. from Figure 5 It shows that compared with Comparative Example 1, the performance of the electrode in Example 1 is significantly improved.

Embodiment 2

[0040] The carbon paper was treated in the air at 550°C, and then degreased and cleaned in ethanol and acetone as the substrate; the concentration was 0.25M SnSO 4 solution, with 0.8M H 2 SO 4 and 0.06 2M OP, mix well to obtain a mixture solution as an electrolyte solution; in the electrolyte solution, in N 2 Constant current density-60mA cm was carried out under the protection of atmosphere -2 Constant potential deposition for 2000s; 0.5M NaHCO in post-treatment electrolyte 3 The electrolytic solution was reduced with -1.2V for 900s; the Sn nanorod catalyst was prepared after washing and drying.

Embodiment 3

[0042] The carbon paper was treated in the air at 550°C, and then degreased and cleaned in ethanol and acetone as the substrate; the concentration was 0.25M SnSO 4 solution, with 0.8M H 2 SO 4 And the gelatin of 0.06M, mix to obtain mixture solution as electrolyte solution; In electrolyte solution, in N 2 Constant current density-60mA cm was carried out under the protection of atmosphere -2 Constant potential deposition for 2000s; 0.5M NaHCO in post-treatment electrolyte 3 The electrolytic solution was reduced with -1.2V for 900s; the Sn nanorod catalyst was prepared after washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com