Aspartic ester self-leveling coating and preparation method thereof

An aspartic acid ester and self-leveling technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor surface condition and inconvenient construction of aspartic acid ester resin, and achieve excellent surface condition and easy operation The effect of prolonging the use time and reducing the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

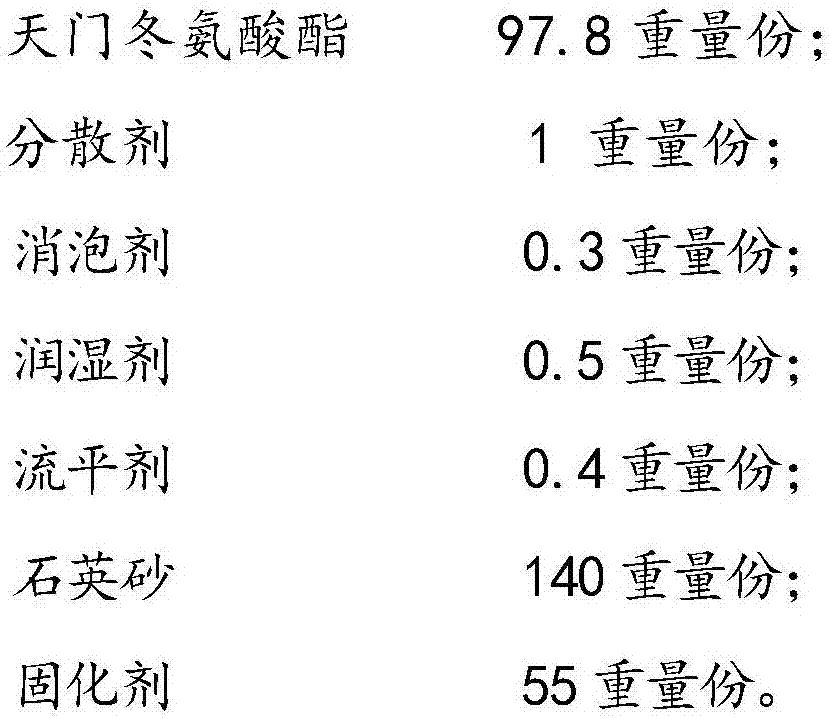

[0019] Embodiment 1 This embodiment discloses a kind of aspartic acid ester self-leveling coating, and described coating comprises following components:

[0020]

[0021] The preparation method of described aspartic acid ester, described method step is as follows:

[0022] Put 14g of 4,4'-diaminodicyclohexylmethane and 63.47g of 3,3'-dimethyl-4,4-diaminodicyclohexylmethane into a 250ml four-neck flask, add 22.27 g of diethyl maleate and 121.6 g of di-n-butyl maleate were added dropwise to the maleic acid ester at room temperature, and the temperature was controlled to be added dropwise below 50° C. under nitrogen protection. After the dropwise addition, the temperature was raised to 70° C., and the mixture was kept warm for 48 hours to discharge to obtain a new type of aspartic acid ester resin.

[0023] This embodiment discloses the preparation method of the coating described in embodiment 1, specifically:

[0024] Add corresponding weight parts of defoamer, leveling age...

experiment example

[0026] 1) Solvent-free and environmentally friendly products, with a solid content of more than 98%, and no heavy metals and plasticizers.

[0027] 2) Good construction and operation performance. At 23°C, the mixing viscosity is about 800cps, and the operation time is 30 minutes.

[0028] 3) Good anti-scratch and wear-resistant effect. Under the environment of 23 ℃, the surface hardness is 2H, the Shore D hardness is above 75, and the abrasion is 20mg.

[0029] 4) Good impact resistance. A 1kg iron ball will not crack when dropped 2m, the elongation of the paint film is 10%, and the tensile strength is about 20MPa.

[0030] 5) Good yellowing resistance. UV lamp 340nm, 0.71w / m2, 1000 hours cycle test △E<1.5. Gained coating properties are tested, and the test results are shown in Table 1:

[0031] Table 1

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com