Fixation rosin ink

A technology of rosin and ink, applied in ink, household utensils, applications, etc., can solve the problem of poor color fixation of ink, achieve good color fixation effect, and help ink retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

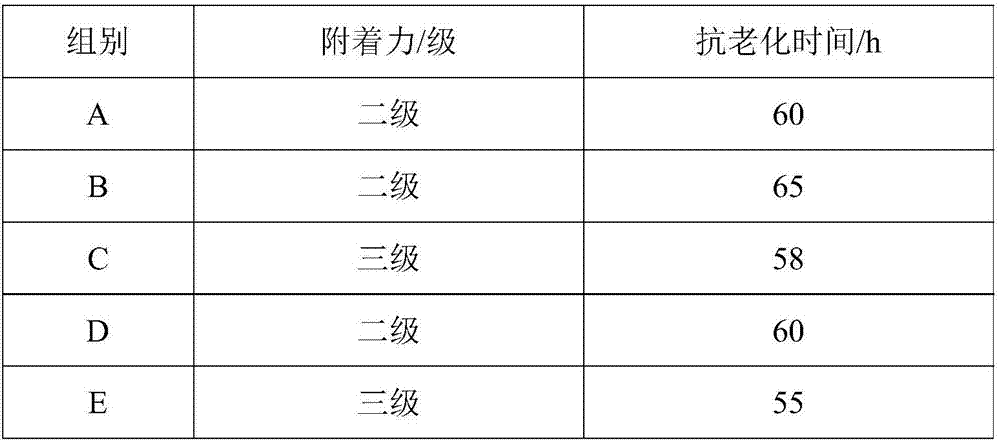

Examples

Embodiment 1

[0025] A color-fixing rosin ink, which is composed of the following components in parts by weight: 40 parts of epoxy resin, 30 parts of polymerized rosin, 15 parts of polyethylene glycol, 9 parts of Cuban gum, 1 part of sodium polyacrylic acid, dicyandiamide 3 parts of amine-formaldehyde polycondensate, 0.5 parts of black pigment.

[0026] The preparation method of described polymerized rosin is:

[0027] S1: Put 200g of industrial rosin in a three-necked flask, then add 1000mL of toluene, stir and heat to 75°C in an oil bath until the rosin is completely dissolved;

[0028] S2: Add 200g of concentrated sulfuric acid into the mixed solution obtained in step S1, heat for 40min, then add 20g of magnesium chloride and 10g of zinc chloride, heat to 120°C, and stir for 8h;

[0029] S3: filter the mixture obtained in step S2, wash the filtrate with deionized water at 85°C, and detect no chloride ions with silver chloride solution acidified with nitric acid;

[0030] S4: Take the f...

Embodiment 2

[0033] A color-fixing rosin ink, in parts by weight, consists of the following components: 115 parts of epoxy resin, 80 parts of polymerized rosin, 60 parts of polyethylene glycol, 22 parts of Cuban gum, 9 parts of polyvinyl alcohol, polydiene 15 parts of propyl dimethyl ammonium chloride, 2 parts of red pigment.

[0034] The preparation method of described polymerized rosin is:

[0035] S1: Put 200g of industrial rosin in a three-necked flask, then add 1000mL of toluene, stir and heat to 75°C in an oil bath until the rosin is completely dissolved;

[0036] S2: Add 200g of concentrated sulfuric acid into the mixed solution obtained in step S1, heat for 40min, then add 20g of magnesium chloride and 10g of zinc chloride, heat to 120°C, and stir for 8h;

[0037] S3: filter the mixture obtained in step S2, wash the filtrate with deionized water at 85°C, and detect no chloride ions with silver chloride solution acidified with nitric acid;

[0038] S4: Take the filtrate obtained i...

Embodiment 3

[0041] A color-fixing rosin ink, in parts by weight, consists of the following components: 45 parts of epoxy resin, 40 parts of polymerized rosin, 20 parts of polyethylene glycol, 11 parts of Cuban glue, 2 parts of polyacrylamide, dicyandiamide 5 parts of amine-formaldehyde polycondensate, 0.7 parts of pigment.

[0042] The preparation method of described polymerized rosin is:

[0043] S1: Put 200g of industrial rosin in a three-necked flask, then add 1000mL of toluene, stir and heat to 75°C in an oil bath until the rosin is completely dissolved;

[0044] S2: Add 200g of concentrated sulfuric acid into the mixed solution obtained in step S1, heat for 40min, then add 20g of magnesium chloride and 10g of zinc chloride, heat to 120°C, and stir for 8h;

[0045] S3: filter the mixture obtained in step S2, wash the filtrate with deionized water at 85°C, and detect no chloride ions with silver chloride solution acidified with nitric acid;

[0046] S4: Take the filtrate obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com