A kind of epoxy system for bio-based electrical insulation and preparation method thereof

An electrical insulation and epoxy system technology, applied in the field of bio-based electrical insulation epoxy system and its preparation, can solve the problems of high cost, long production cycle of tung oil, limited application scope of tung oil acid anhydride insulation material system, etc., and achieves low cost , The effect of low production cost and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

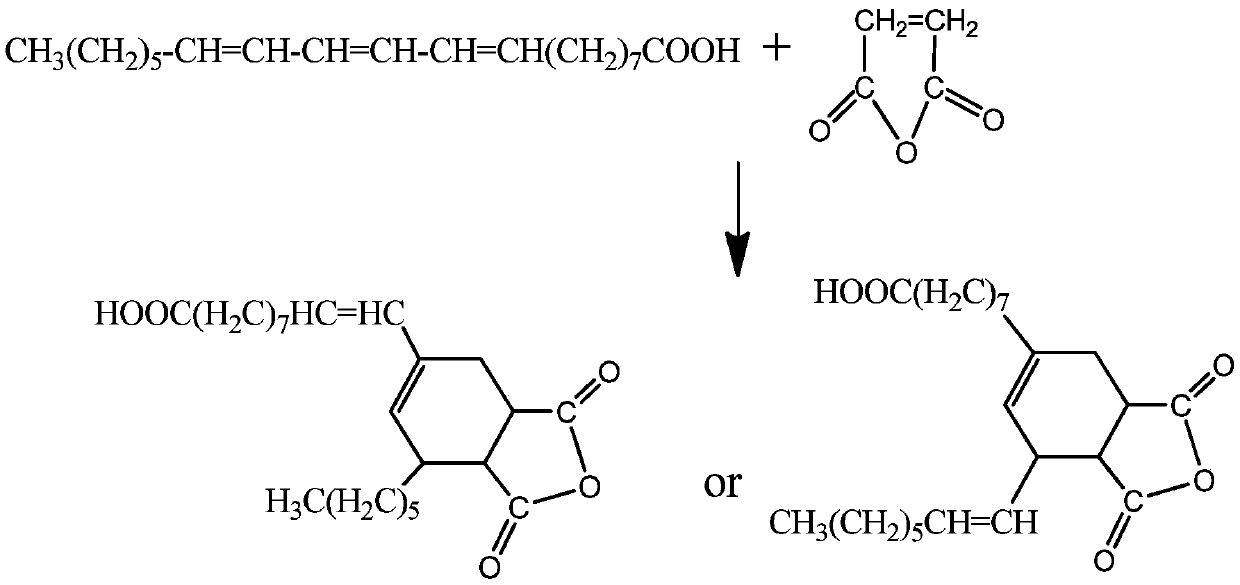

Method used

Image

Examples

Embodiment 1

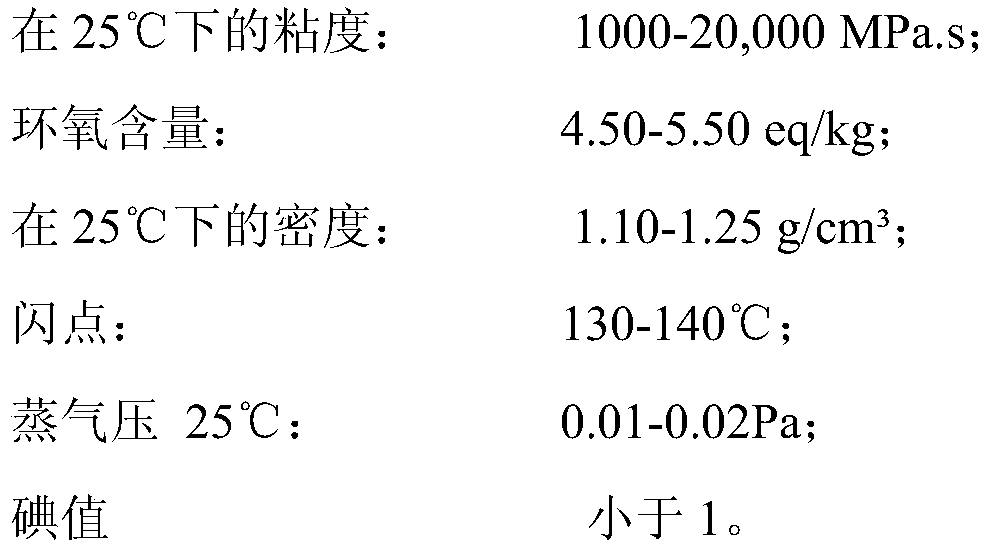

[0051] Mix 2 parts of benzoyl peroxide (BPO) and 98 parts of epoxy-based soybean oil, vacuumize, heat to 80°C in a nitrogen atmosphere, react for 2 hours, and cool to 40°C to prepare epoxy-based soybean oil Oligomers, wherein the resulting oligomers have an iodine value of less than 1;

[0052] 10g of castor oil was added to 89.8g of bisphenol epoxy resin DER331, and then 0.02g of 2-phenylimidazole solution (30%) was added. Then the temperature was raised to 140° C., and the reaction was carried out for 2 hours. Cool to 100 degree then, add above-mentioned weight 40g above-mentioned epoxy base soybean oil oligomers of above-mentioned preparation to adjust viscosity, cool to normal temperature stand-by.

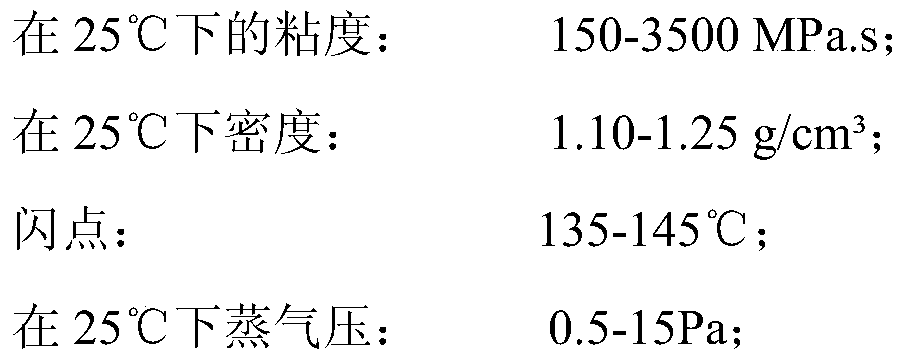

[0053] At 140°C, react 15 parts by mass of castor oil with 25 parts by mass of tetrahydrophthalic anhydride for two hours, cool to 100°C and add 50% by mass of methyltetrahydrophthalic anhydride relative to the reaction product to adjust the viscosity, and add the relative re...

Embodiment 2

[0056] Mix 1 part of azobisisobutyronitrile and 99 parts of epoxy-based castor oil, vacuumize, heat to 95°C in a nitrogen atmosphere, react for 2 hours, and cool to 40°C to prepare epoxy-based castor oil oligomerization Object, wherein, the iodine number of obtained oligomer is lower than 1;

[0057] Add 15g of castor oil to 85g of bisphenol epoxy resin DER331, then add 0.05g of sodium methylate methanol solution (50%), react at 160°C for 3 hours, then cool to 120°C, add 30g of the above epoxidized castor oil to adjust the viscosity , cooled to room temperature for later use.

[0058] At a temperature of 150°C, mix 20 parts by mass of cardanol and 80 parts by mass of phthalic anhydride, and react until the acid value of the system reaches 3 mg KOH / g. After cooling to room temperature, add 1 mass % of N-methylimidazole relative to the reaction product , stirred for 30 minutes, cooled to room temperature for later use. Then mix the above bio-based epoxy resin and anhydride cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com