Method for directly growing tungsten oxide film on conducting glass

A technology of conductive glass and tungsten oxide, which is applied in the field of materials, can solve the problems of complicated process, difficult to obtain target products, and long time, and achieve the effect of simple preparation process, low cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Dissolve 20mmol tungsten hexachloride in a mixed solution of 20ml absolute ethanol and 20ml tetrahydrofuran.

[0033] 2) Add 1ml of polyethylene glycol to the solution obtained in 1), then transfer it to a polytetrafluoroethylene reactor, and then put a piece of 2.5×5 cm in the reactor 2 The FTO conductive glass with its conductive side facing down was placed in an oven at 180 °C for 6 h, and then cooled to room temperature naturally.

[0034] 3) Take out the FTO conductive glass in 2) the reaction kettle, wash it with absolute ethanol, and put the obtained film in a muffle furnace at 400 °C for 1 h, and the film turns from blue to white, and the performance to be tested is obtained. Tungsten oxide film.

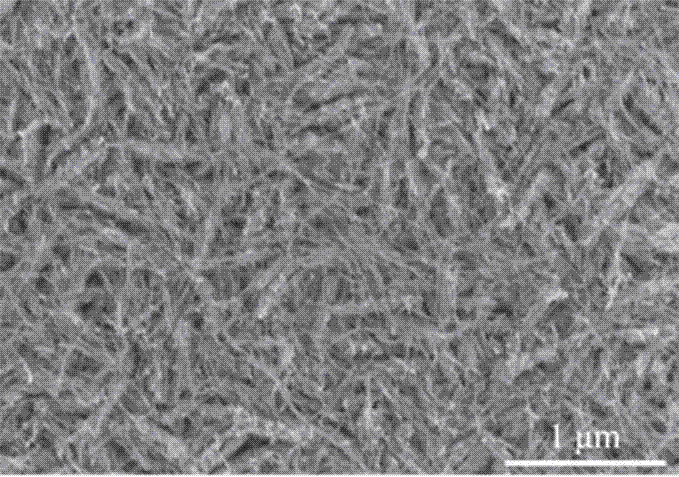

[0035] The SEM photo of the tungsten oxide film prepared in this embodiment is as follows figure 1 As shown, it is a nanocluster formed by some nanowires; this structure is relatively uniform, and the injection and extraction of ions are easier, and it is suitabl...

Embodiment 2

[0038] 1) Dissolve 20mmol tungsten hexachloride in a mixed solution of 30ml absolute ethanol and 10ml tetrahydrofuran.

[0039] 2) Add 1ml of polyethylene glycol to the solution obtained in 1), then transfer it to the core of the polytetrafluoroethylene reactor, and then put a piece of 2.5×5 cm in the core of the reactor 2 FTO conductive glass, with its conductive side facing down, was placed in an oven at 180°C for 6 hours, and cooled naturally to room temperature.

[0040] 2) Take out the FTO conductive glass in the reaction kettle, wash it with absolute ethanol, put the obtained film in a muffle furnace at 400 °C for 1 h, and the film turns from blue to white, and the tungsten oxide with the performance to be tested is obtained. film. figure 2 It is the SEM photograph of the tungsten oxide film prepared in Example 2, which is in the form of nanosheets. It is calculated that the coloring time of the tungsten oxide electrochromic device is about 23 s and the fading time is ...

Embodiment 3

[0042] 1) Dissolve 20mmol tungsten hexachloride in a mixed solution of 10ml absolute ethanol and 30ml tetrahydrofuran.

[0043] 2) Add 1ml of polyethylene glycol to the solution obtained in 1), then transfer it to the core of the polytetrafluoroethylene reactor, and then put a piece of 2.5×5 cm in the core of the reactor 2 FTO conductive glass, with its conductive side facing down, was placed in an oven at 180°C for 12 hours, and cooled naturally to room temperature.

[0044] 2) Take out the FTO conductive glass in the reaction kettle, wash it with absolute ethanol, put the obtained film in a muffle furnace at 400 °C for 1 h, and the film turns from blue to white, and the tungsten oxide with the performance to be tested is obtained. film. image 3 It is a SEM photo of the tungsten oxide thin film prepared in Example 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com