Enhanced hydroacoustic cavitation treatment device

A technology of treatment device and water inlet pipe, which is applied in special compound water treatment, water/sewage treatment, water/sewage treatment equipment, etc. Ideal and other issues, to achieve the effect of favorable degradation, improved treatment effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

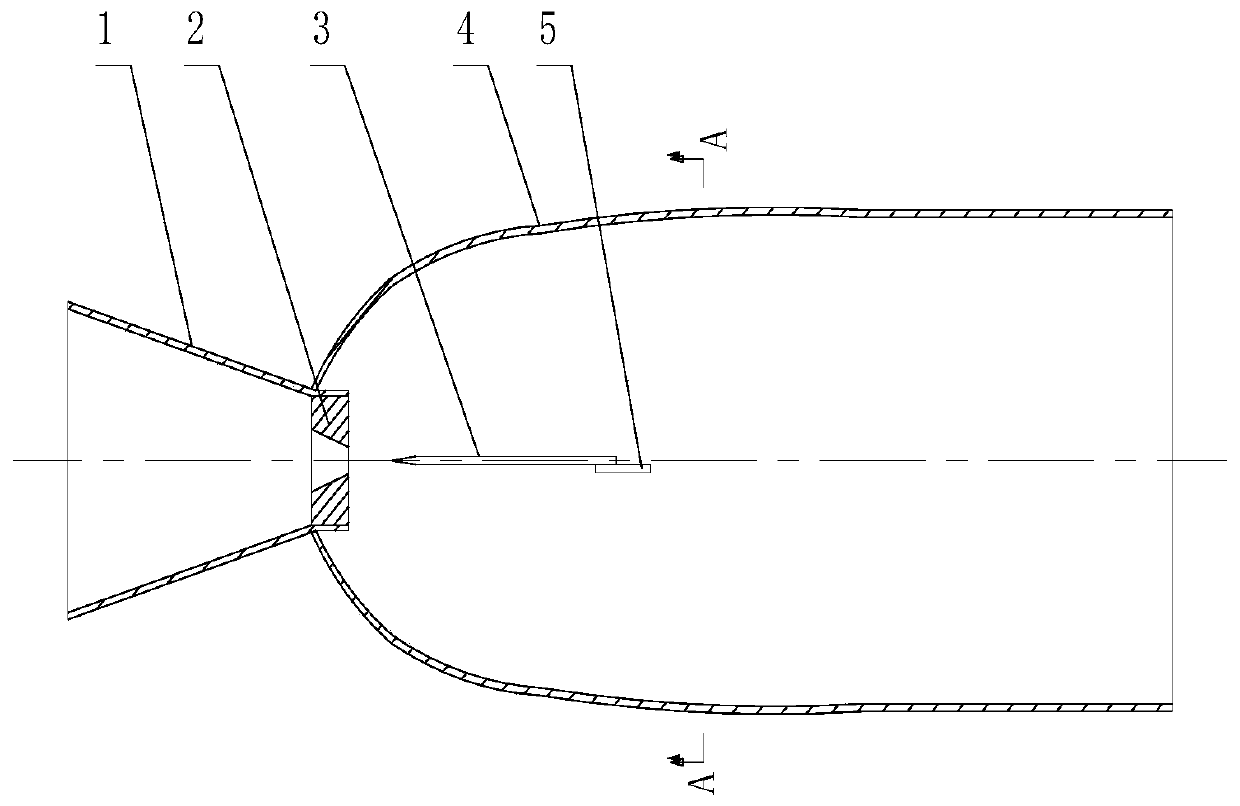

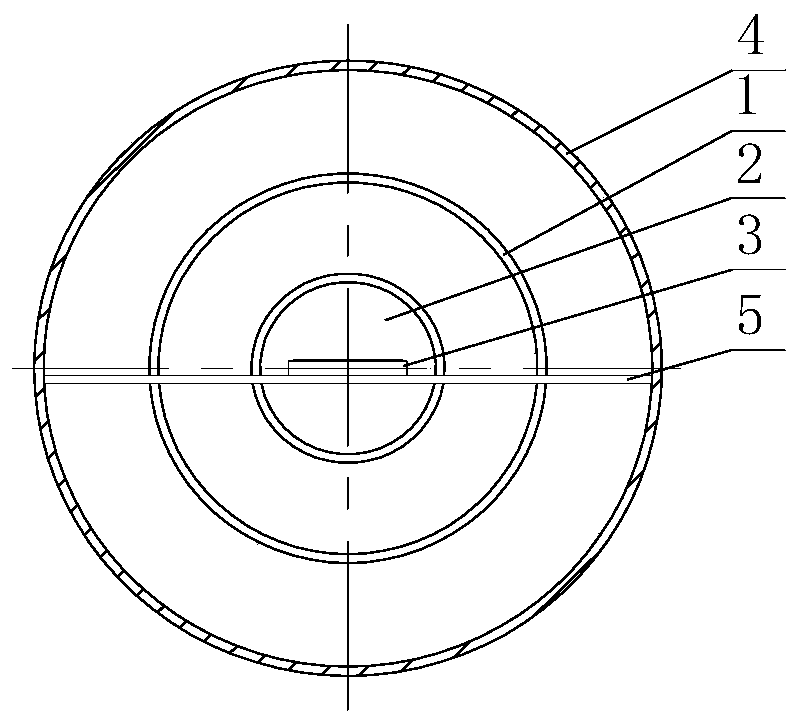

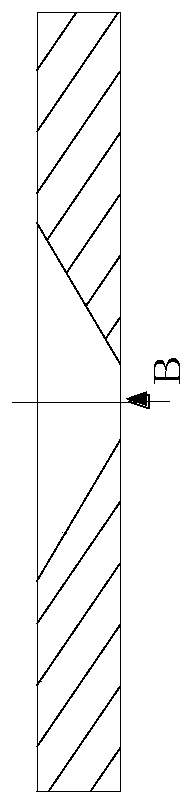

[0038] Depend on figure 1 and 2 It can be seen that the enhanced hydroacoustic cavitation treatment device of this embodiment includes a water inlet pipe 1 , a cavitation pipe 4 , a nozzle 2 , a reed 3 and a fixing plate 5 . Wherein, the inlet end of the water inlet pipe 1 communicates with the water inlet pump, the inner diameter of the inlet end is 60 mm, and the inner diameter of the outlet end is 48 mm. A nozzle 2 is set on the outlet end of the water inlet pipe 1, and the nozzle 2 extends to the inlet of the cavitation pipe 4, and a rectangular nozzle is processed on the outlet end surface of the nozzle 2, and the center line of the rectangular nozzle coincides with the central axis of the water inlet pipe 1, that is The rectangular spouts are distributed symmetrically on the center line of the water inlet pipe 1, the opening width h of the rectangular spouts is 1mm, and the length l is 24mm.

[0039] The water inlet pipe 1 and the cavitation pipe 4 are hermetically con...

Embodiment 2

[0048] Depend on Figure 6 and 7 It can be seen that the inner diameter of the inlet end of the water inlet pipe 1 of the present embodiment is 60mm, and the inner diameter of the outlet end is 48mm. A nozzle 2 is set on the outlet end of the water inlet pipe 1, and the nozzle 2 extends to the inlet of the cavitation pipe 4, and a rectangular nozzle is processed on the outlet end surface of the nozzle 2, and the center line of the rectangular nozzle coincides with the central axis of the water inlet pipe 1, that is The rectangular spouts are distributed symmetrically on the center line of the water inlet pipe 1, the opening width h of the rectangular spouts is 1mm, and the length l is 24mm.

[0049] The water inlet pipe 1 and the cavitation pipe 4 are hermetically connected, that is, the joint is filled with a sealing material to realize the hermetic connection.

[0050] Establish a coordinate system on the plane where the longitudinal section of the cavitation pipe 4 is loc...

Embodiment 3

[0061] Depend on Figure 8 and 9 It can be seen that the inlet end of the water inlet pipe 1 in this embodiment communicates with the water inlet pump, the inner diameter of the inlet end is 60mm, and the inner diameter of the outlet end is 48mm. A nozzle 2 is set on the outlet end of the water inlet pipe 1, and the nozzle 2 extends to the inlet of the cavitation pipe 4, and a rectangular nozzle is processed on the outlet end surface of the nozzle 2, and the center line of the rectangular nozzle coincides with the central axis of the water inlet pipe 1, that is The rectangular spouts are distributed symmetrically on the center line of the water inlet pipe 1, the opening width h of the rectangular spouts is 1mm, and the length l is 24mm.

[0062] The water inlet pipe 1 and the cavitation pipe 4 are hermetically connected, that is, the joint is filled with a sealing material to realize the hermetic connection.

[0063] Establish a coordinate system on the plane where the longi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com