Method for preparing graphite-titanium low-valence oxide composite material

A technology of titanium low-valent oxides and composite materials, applied in the direction of titanium low-value oxides, titanium oxide/hydroxide, etc., can solve the problem of harsh reaction atmosphere, long reaction process time, and difficult control of physical and chemical properties of reaction products, etc. problems, to achieve the effect of low production equipment and production environment requirements, convenient large-scale industrial production, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of graphite-titanium subvalent oxide composite material comprises the following steps:

[0030] a. TiO 2 Mix with graphite powder at a weight ratio of 1:0.2 to 0.4, and shape to obtain a molding material;

[0031] b. Put the molding material into the crucible, then evenly cover the surface of the molding material with graphite powder, heat it to 1100-1300°C in an air atmosphere, reduce it for 5-40 minutes, then pour it into the graphite powder and cool it to room temperature to obtain the reduced product; Among them, the thickness of the graphite powder covering is ≥0.5cm; the function of covering the graphite powder is to prevent the oxidation of the sample during the reduction process; adding graphite powder for cooling is also to avoid the oxidation of the product during the cooling process.

[0032] c. Crushing the reduced product to obtain a composite material.

[0033] Among them, TiO 2 It can be replaced by metatitanic acid, and the mixi...

Embodiment 1

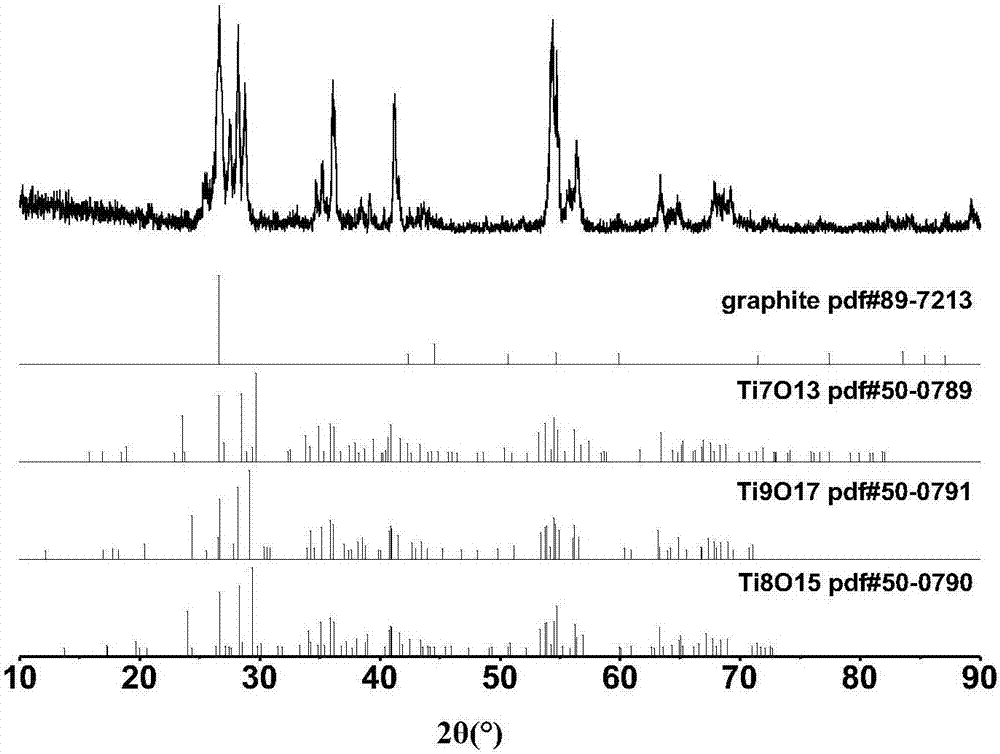

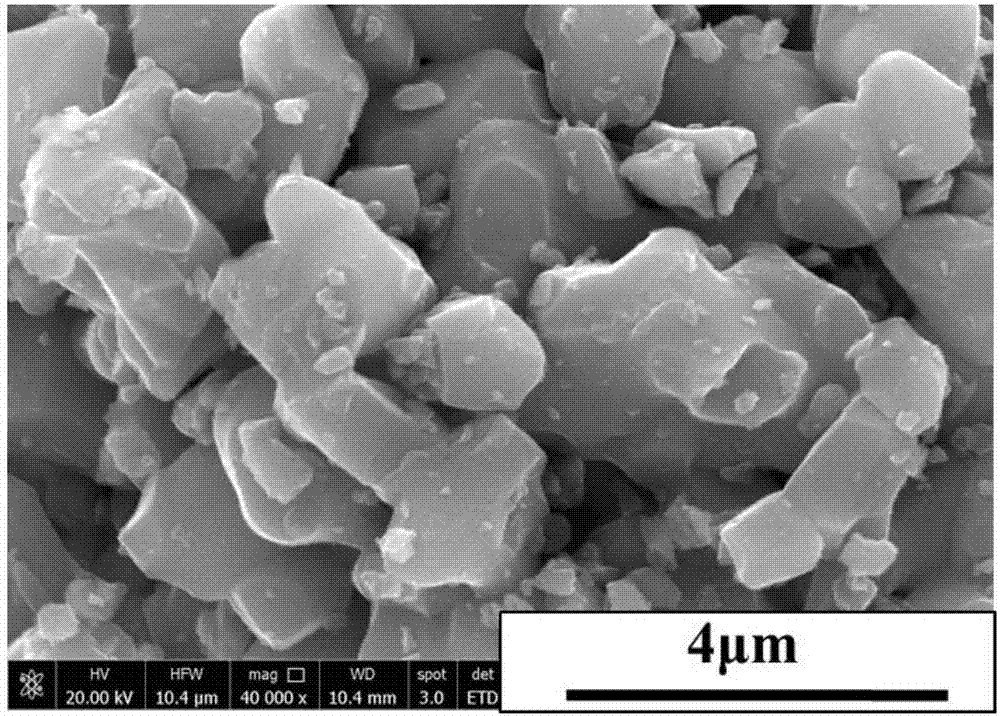

[0045] Take 100gTiO 2 , 30g graphite (TiO 2 and graphite particle size are all less than 15 μm, impurity content is all less than 1%), after mixing evenly, press into a block, the mixture block is placed in a crucible, and graphite powder is evenly covered on the material surface (graphite powder thickness 0.5cm), and then placed into a high-temperature furnace, under an air atmosphere, at a reduction temperature of 1250°C, and a reduction time of 20 minutes. After reaching the reduction time, the crucible is quickly taken out and the material is poured into graphite powder for protection. After cooling to room temperature, the reduction product is ball-milled to obtain a composite Material. The content of titanium in the composite material is 57.63wt%, the content of oxygen is 34.76%wt, and the content of carbon is 7.61%wt. Product XRD see figure 1 , proving that its phase composition is low-valent titanium oxide and graphite. Product SEM picture see figure 2 , it can b...

Embodiment 2

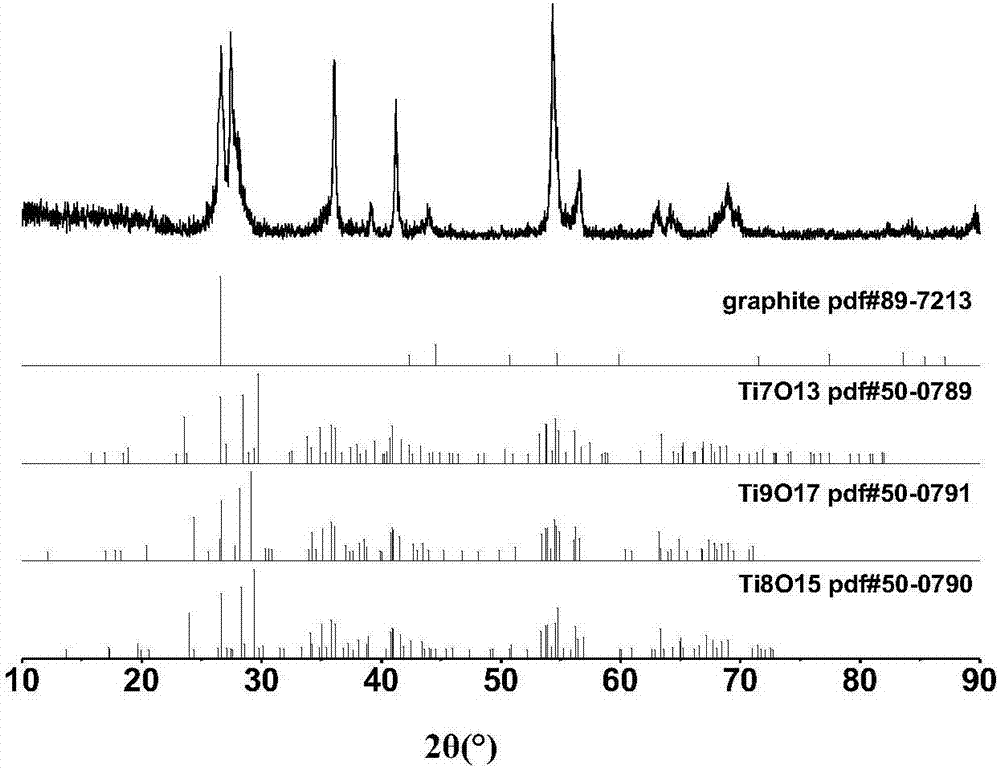

[0047] Take 100gTiO 2 , 20g graphite (TiO 2 and graphite particle size are all less than 15 μm, and impurity content is all less than 1wt%), after mixing evenly, press into a block, put the mixture block into a crucible, and evenly cover the surface of the material with graphite powder (graphite powder thickness 1cm), and then place In a high-temperature furnace, under an air atmosphere, the reduction temperature is 1250°C, and the reduction time is 10 minutes. After the reduction time is reached, the crucible is quickly taken out and the material is poured into graphite powder for protection. After cooling to room temperature, the reduction product is ball-milled to obtain a composite material . The content of titanium in the composite material is 59.68wt%, the content of oxygen is 35.54wt%, and the content of carbon is 4.78wt%. The particle size of the product is less than 10μm, XRD sees image 3 , proving that its phase composition is low-valent titanium oxide and graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com