Method for preparing aqueous dispersion nano-cuprous oxide/graphene composite powder

A nano-cuprous oxide and graphene composite technology, applied in the oxidation water/sewage treatment, medical preparations containing active ingredients, light water/sewage treatment, etc., to achieve low production equipment requirements, excellent photocatalytic degradation of dyes, Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

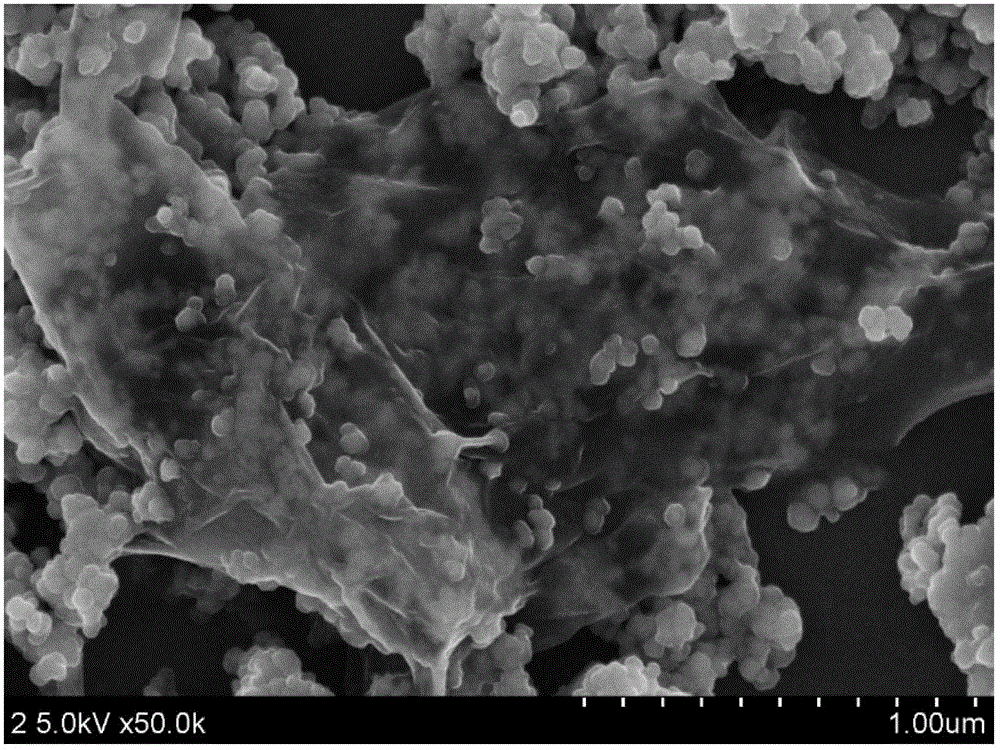

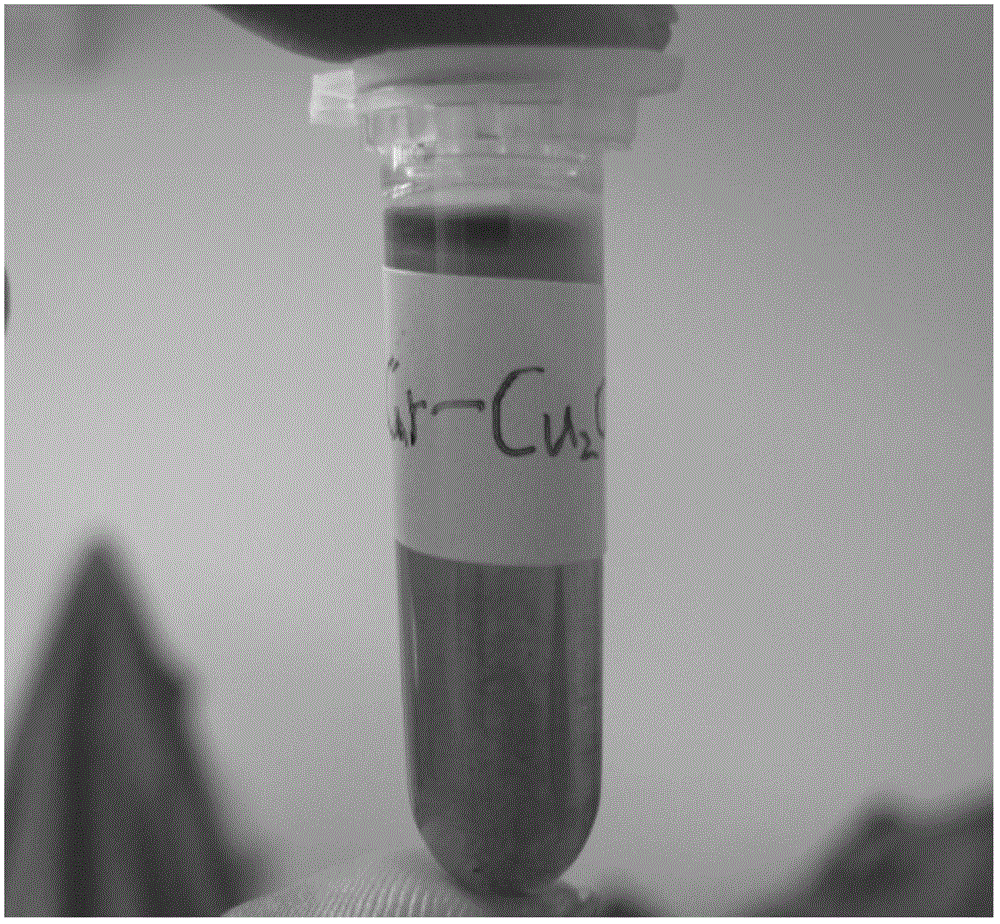

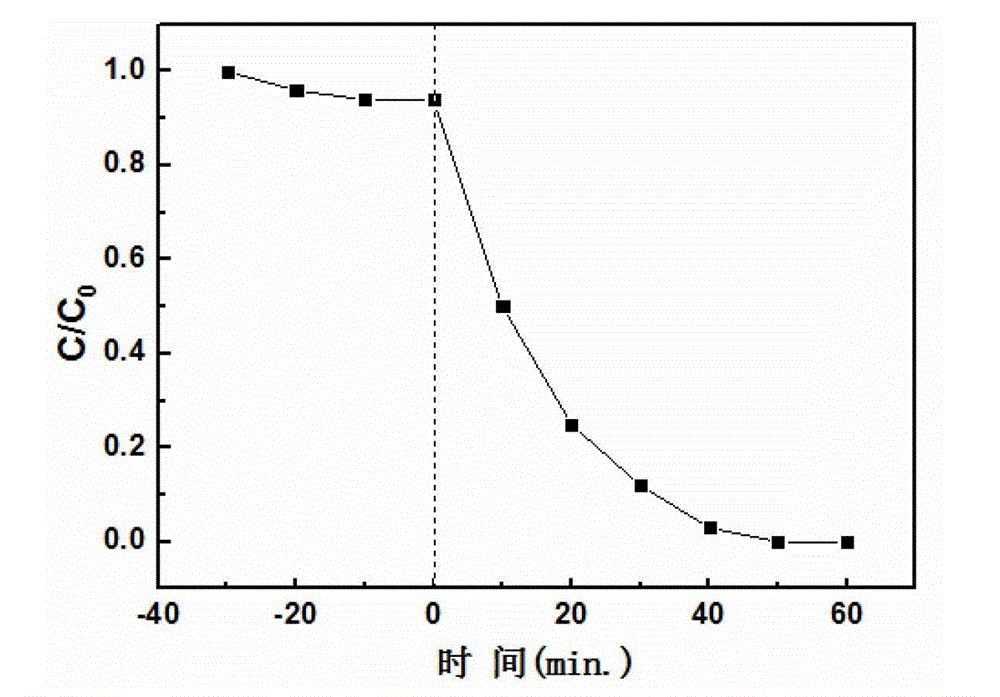

[0027] At room temperature, weigh 100 mg of graphite oxide, 1 g of sodium polystyrene sulfonate, and 1 g of anhydrous copper nitrate into a beaker, then add 100 mL of deionized water, and ultrasonically disperse at a power of 300 W for 45 minutes. After the dispersion is uniform, dropwise add 0.1 mL hydrazine hydrate solution (mass concentration 80%), then pour the above reaction solution into a three-necked flask, be warming up to 100°C, and react for 10h. After the reaction, the Cu was collected by suction filtration 2 The O / graphene composite powder was washed with deionized water, and then the product was dried at 60°C for 18h. figure 1 From the field emission scanning electron microscope photograph of the powder synthesized in this example, it can be seen that the cuprous oxide nanoparticles are uniformly attached to the graphene surface. figure 2 From the photo of the dispersion effect of the synthetic powder in this example in water, it can be seen that the powder has...

Embodiment 2

[0029] At room temperature, weigh 80 mg of graphite oxide, 400 mg of sodium dodecyl benzene sulfonate, and 400 mg of anhydrous copper nitrate into a beaker, then add 160 mL of deionized water, and ultrasonically disperse at a power of 200 W for 60 min. Add 128 μL of hydrazine hydrate solution (mass concentration 50%), pour the above reaction solution into a three-necked flask, heat up to 90 ° C, and react for 12 h. After the reaction, the Cu was collected by suction filtration 2 O / graphene composite powder was washed with deionized water, and then the product was dried at 40°C for 24h. The cuprous oxide in the product is well combined with graphene; it has good dispersibility in water; it has good visible light catalytic degradation of cationic dyes and anti-tumor cell effects.

Embodiment 3

[0031] At room temperature, weigh 150 mg of graphite oxide, 1.2 g of sodium dodecyl sulfate, and 300 mg of anhydrous copper nitrate into a beaker, then add 100 mL of deionized water, and ultrasonically disperse at a power of 400 W for 30 minutes. After the dispersion is uniform, dropwise add 0.05mL hydrazine hydrate solution (mass concentration 30%), then pour the above reaction solution into the three-necked flask, be warming up to 110°C, and react for 8h. After the reaction, the Cu was collected by suction filtration 2 O / graphene composite powder was washed with deionized water, and then the product was dried at 80°C for 12h. The cuprous oxide in the product is well combined with graphene; it has good dispersibility in water; it has good visible light catalytic degradation of cationic dyes and anti-tumor cell effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com