Method for tail gas dust collection and discharging in production of titanium tetrachloride

A technology of titanium tetrachloride and exhaust gas, applied in the direction of titanium halide, etc., can solve the problems of blockage of the dust collection and feeding pipeline, easy jamming of the feeding valve, etc., and achieve the effect of ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

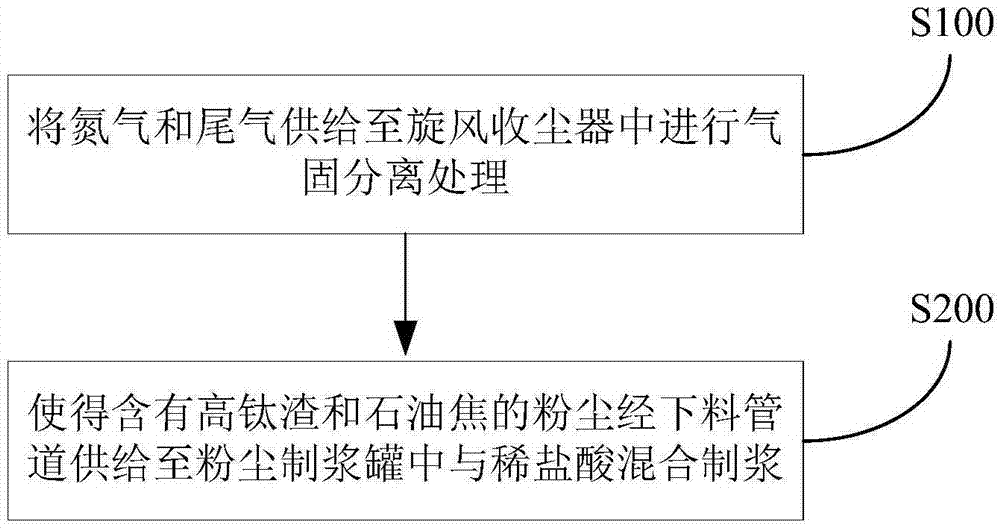

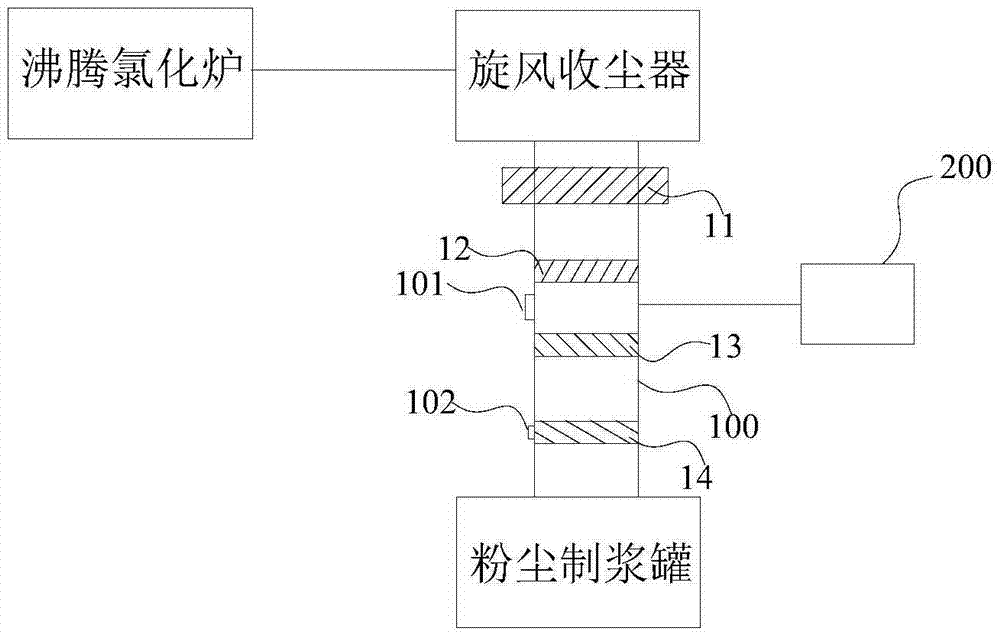

[0027] In one aspect of the present invention, the present invention provides a method for dust collection and blanking of tail gas in the production of titanium tetrachloride. According to an embodiment of the present invention, the tail gas contains at least one of gaseous titanium tetrachloride, high-titanium slag and petroleum coke. According to a specific embodiment of the present invention, the method includes: (1) supplying nitrogen and the tail gas to a cyclone dust collector for gas-solid separation, so as to separate and obtain gaseous titanium tetrachloride and high-titanium slag and petroleum coke (2) Turn on the electric heating element and the rotary feeding valve on the feeding pipeline, and open the pipeline on the feeding pipeline to seal the nitrogen inlet and the rotary valve to seal the nitrogen inlet, and open the No. The No. 1 valve opens the No. 2 valve for a predetermined time, so that the dust containing high-titanium slag and petroleum coke is supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com