Holographic laser printing transfer film and production process for metal package

A metal packaging and production process technology, applied in printing, copying/marking methods, temperature recording methods, etc., can solve the problems that limit the application of laser holography technology, and achieve the effects of strong visual impact, high elongation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

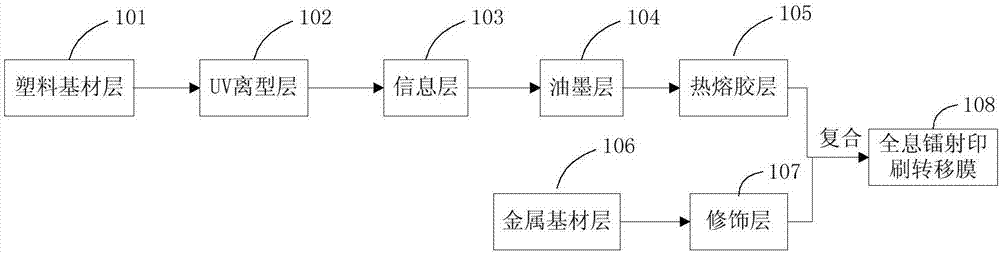

[0040] Such as figure 1 As shown, a holographic laser printing transfer film for metal packaging, including a plastic substrate layer 1, a UV release layer 2, an information layer 3, an ink layer 4, an aluminum reflective layer 5, and a hot melt adhesive layer stacked in sequence 6. Modification layer 7 and metal substrate layer 8; wherein, the plastic substrate layer 1 is PET film, PMMA film or BOPP film, and the thickness is generally 10-30 μm; the UV release layer 2 is mainly made of polyurethane acrylic It is composed of ester, silicone modified resin, reactive diluent and photoinitiator, and the coating dry weight of UV release layer 2 is 0.7-1.2g / m 2 .

[0041] The information layer 3 includes a resin and a solvent, wherein the resin is one or more of a thermosetting acrylic resin and an amino resin; the solvent is one or more of ethanol, butanone, methyl ethyl ketone, and n-butanol kind. The coating dry weight of information layer 3 is 0.9-1.3g / m 2 .

[0042] The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com