Preparation method of inner-fluorine outer-silicon car rubber tube

A technology of outer silicon and rubber tube, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of lack of oil and gas penetration resistance, low cost, etc., to achieve excellent high temperature resistance to oil and gas penetration performance, prevent aging damage, The effect of excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

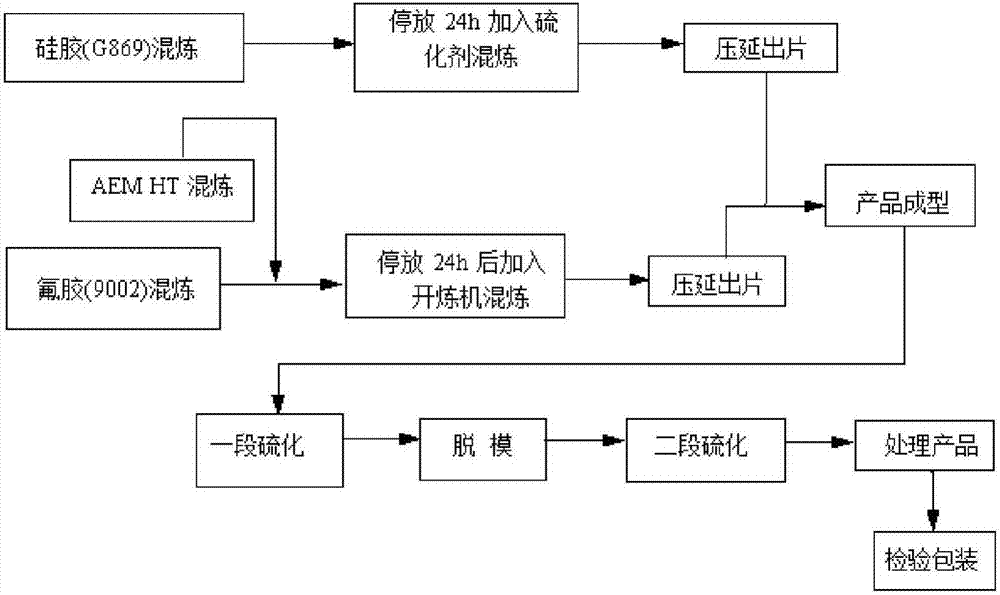

[0036] Embodiment 1: as figure 1 Shown, a kind of preparation method of inner fluorine outer silicon car rubber hose comprises the following steps;

[0037] Step 1. Select raw material steps:

[0038] 1. Raw materials for silica gel mixing:

[0039] Silicone rubber (brand: G869), defrosting agent (F-10), special adhesive (oligomer of amino-containing alkoxysilane and vinyl-containing alkoxysilane), iron red (as a physical Endothermic agent), vulcanizing agent (DBPH), a small amount of meteorological silica;

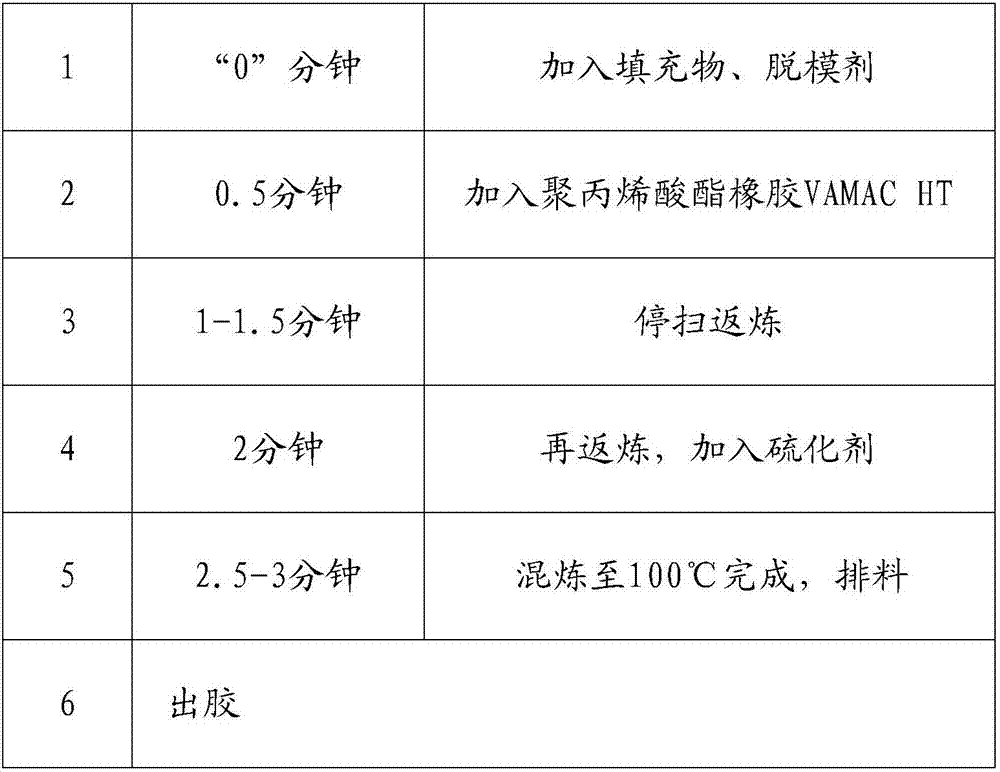

[0040] 2. Raw materials for polyacrylate rubber VAMAC mixing:

[0041] Polyacrylate rubber VAMAC (HT), carbon black (N550), light MgO, release agent, titanium dioxide, Ca(OH) 2 , polyethylene wax, stearic acid, sodium stearate, potassium stearate, cytidine triphosphate CTP;

[0042] 3. Raw materials for fluororubber FKM mixing:

[0043] Fluorine rubber FKM (9002), carbon black (N990), light MgO, stearic acid, vulcanizing agent (DBPH);

[0044] 4. Materials for the bl...

Embodiment 2

[0070] A preparation method for a car rubber hose with inner fluorine and outer silicon, a turbocharger-intercooler air inlet and outlet hose, the lining material is made of AEM-fluororubber FKM blended modified material instead of pure fluororubber FKM material, to achieve improved Performance, while reducing the dual requirements of cost.

[0071] The invention adopts the method of blending modification to carry out blending modification of AEM rubber and fluorine rubber FKM rubber to obtain a new material with high performance and low cost.

[0072] The invention realizes co-vulcanization of AEM and fluororubber FKM, and achieves certain mechanical strength, weather resistance and good process performance, thereby making up for the shortcomings of simply using AEM and fluororubber FKM.

[0073] The invention solves the bonding problem of the inner liner layer of the mixed rubber and the silicone rubber layer. Due to the different properties of the interface, the bonding of ...

Embodiment 3

[0084] Embodiment 3: as figure 1 as shown,

[0085] A method for preparing a car rubber hose with inner fluorine and outer silicon, comprising the following steps;

[0086] The silica gel mixing process steps are as follows:

[0087] The speed ratio of the rollers of the double-roll mill is 1.2 to 1.4, and the fast roller is behind. The higher speed ratio leads to faster mixing, and the lower speed ratio can make the film smooth.

[0088] The roller must have cooling water, and the mixing temperature should be below 40°C to prevent scorching or volatilization loss of vulcanizing agent.

[0089] When mixing, the roller distance is small (1-5mm) at the beginning, and then gradually enlarged.

[0090] Step 1. Add the materials weighed according to the formula ratio at one time, the feeding and operation sequence: raw rubber (covering roll) → defrosting agent → heat-resistant additive (colorant) → thin pass 5 times → blanking, re-milling → vulcanizing agent → thin pass → park ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com