Weather-resistant wood and forming method thereof

A molding method and finished product technology, applied in the pretreatment of molding materials, other household appliances, wood processing appliances, etc., can solve the problems of limited service life, limited physical properties, and susceptibility to climate and environmental influences, so as to avoid consumption , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

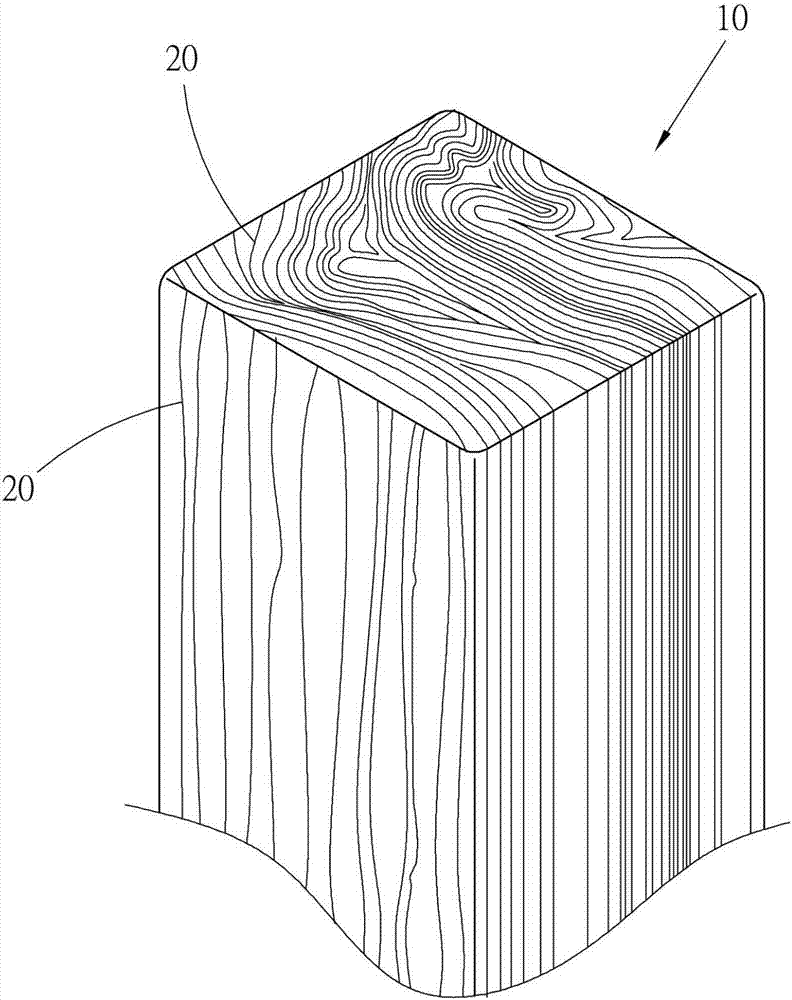

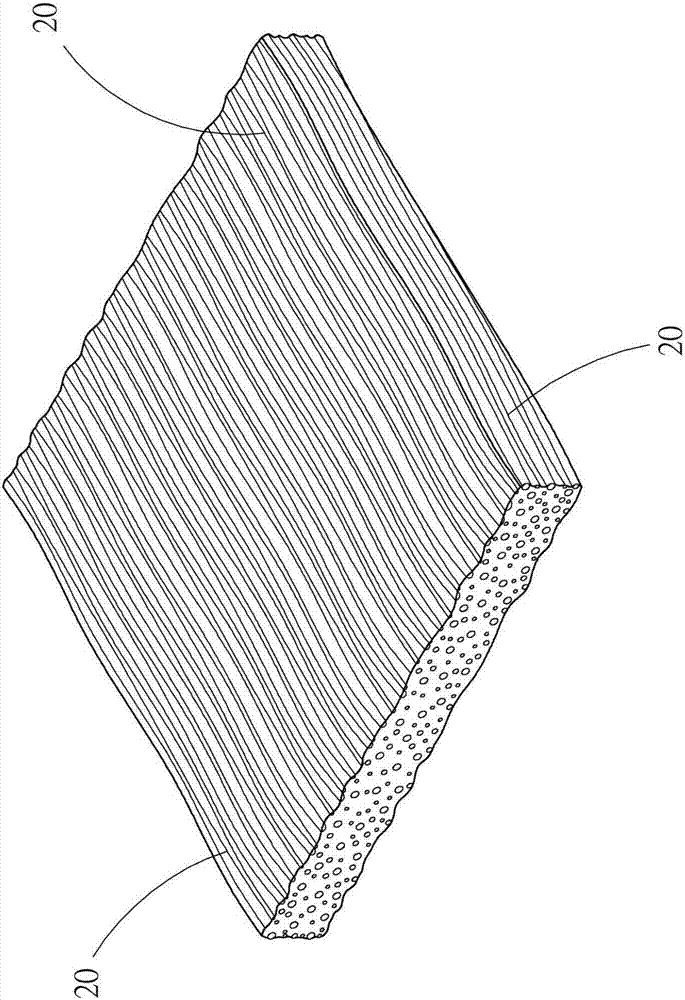

[0025] The invention provides a Zhou Bo wood and a forming method thereof. The method provided by the present invention makes natural plant fibers or synthetic fibers by the cyclic polymerization technology figure 1 As shown in the cycle wood 10, the cycle wood 10 has excellent physical properties, including: high hardness, insect resistance, water resistance, fire resistance and other characteristics. The cycles mentioned are electromagnetic waves. Since the electromagnetic wave is a cycle, the applicant refers to the wood made by the technology of the present invention as a cycle wood. The following describes the Zhoubomu 10 of the present invention and its molding method.

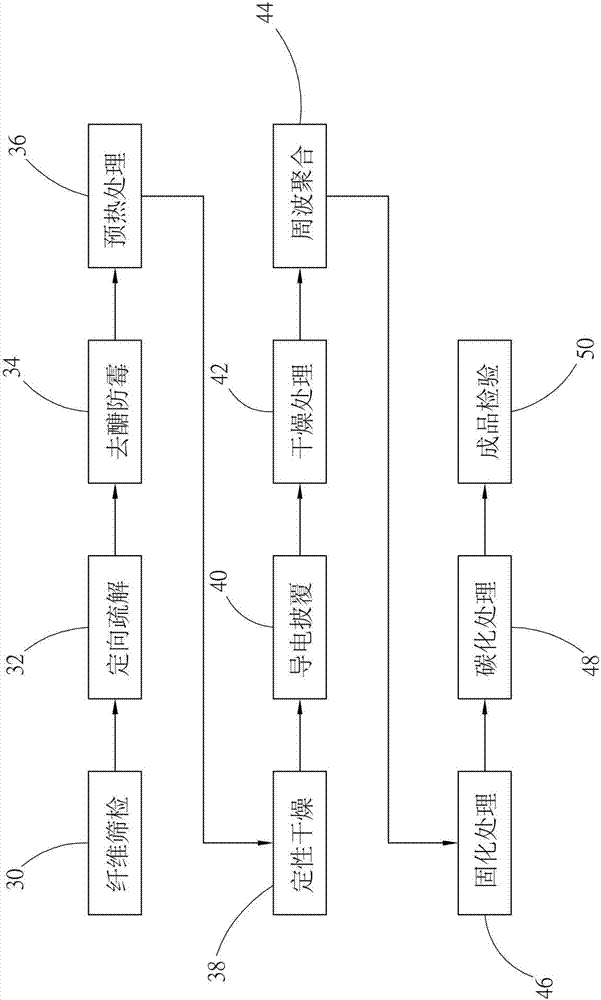

[0026] See figure 2 , Showing the manufacturing process of the molding method of Zhou Bomu of the present invention, the molding method includes but not limited to the following steps: fiber screening 30, directional disintegration 32, sugar removal and anti-mold 34, pre-heat treatment 36, qualitative dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com