A kind of diffusion welding device for large-size sapphire light window and welding method thereof

A technology of diffusion welding and welding method, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc. It can solve the problems that sapphire materials cannot be used and angled welding cannot be solved, so as to prevent pressure slippage, Guarantee the effect of quality and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

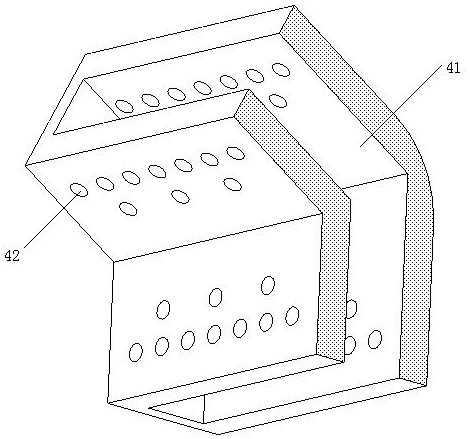

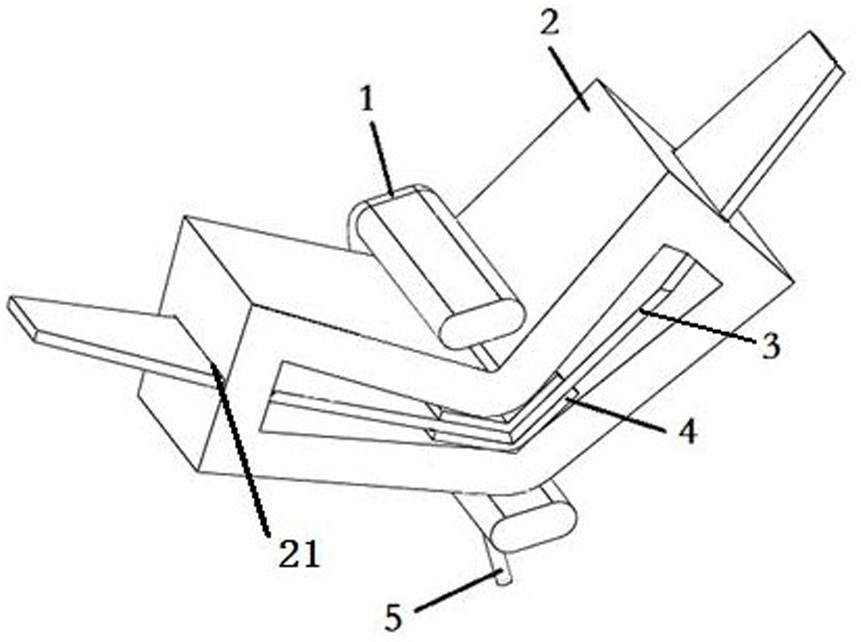

[0038] This embodiment is used for the diffusion welding device of the large-size sapphire light window, such as figure 1 As shown, the large-size sapphire light window is formed by two large-size sapphire plates 3 through diffusion welding to form a bending structure, and the bending angle of the bending structure is 120°; the diffusion welding device includes a tungsten heating element 4 with a bending structure , the center of the tungsten heating element 4 is provided with an embedded groove 41 which is matched with a large-size sapphire light window; a ZrO2 insulating material layer 2, the ZrO2 insulating material layer covers the outer surface of the tungsten heating element 4, and the ZrO2 insulating material layer 2 The geometric symmetry center of ZrO2 coincides with the geometric symmetry center of the tungsten heating element 4; in addition, the side wall of the ZrO2 insulation material layer 2 is provided with a connecting hole, and the two ends of the ZrO2 insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com