Heavy and medium plate mill rough rolling and longitudinal rolling pass reduction distribution method

A technology of reduction and rough rolling, applied in metal rolling, tension/pressure control, etc., can solve the problem of difficulty in meeting the rolling requirements of different medium and thick steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

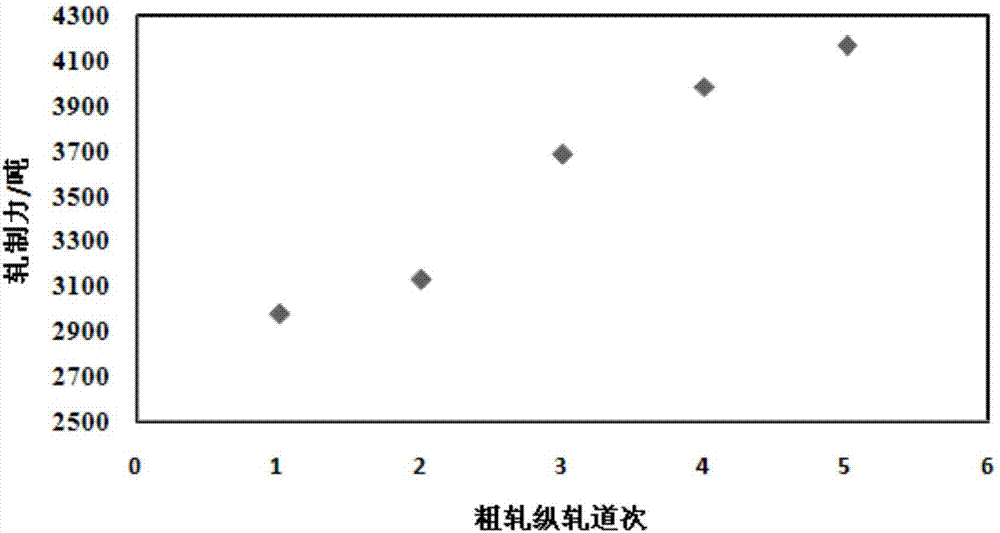

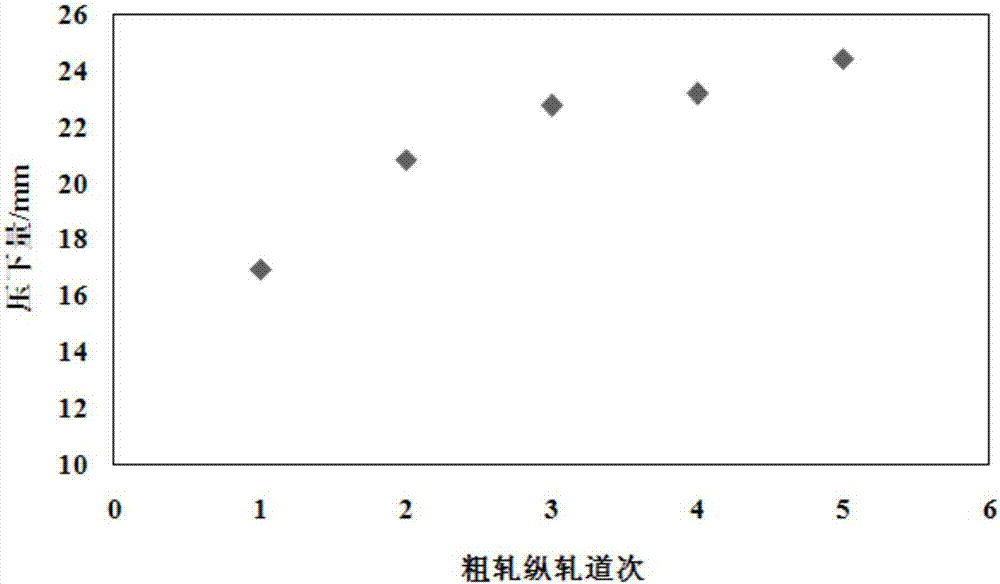

[0029] 115mmQ390D

[0030] Blank shape: 400*2500*3500

[0031] Baking temperature: 1180

[0032] Rolling specifications: 115*2962*9864mm

[0033] Temperature multiple: 1.7

[0034] Rough rolling and longitudinal rolling slope K: 0.9

[0035] Number of rough rolling and longitudinal rolling passes n: 5

[0036] Maximum depression: 40mm

[0037] Rolling procedure:

[0038]

[0039]

Embodiment 2

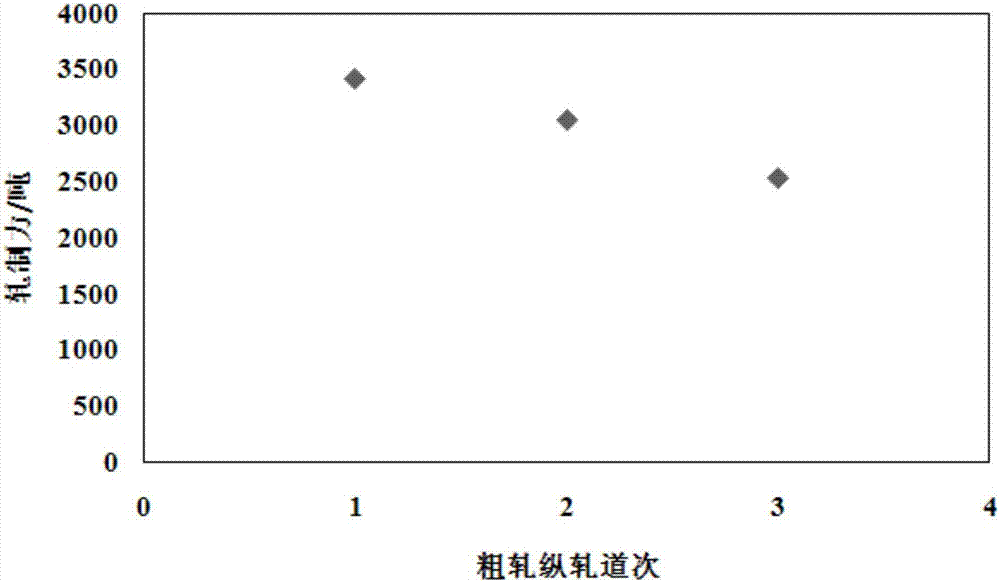

[0041] 24mmQ235+304 composite board

[0042] Blank shape: 150*1600*3100

[0043] Baking temperature: 1220

[0044] Rolling specification: 24*1600*19375mm

[0045] Temperature multiple: 2

[0046] Rough rolling and longitudinal rolling slope K: 1.2

[0047] Number of rough rolling and longitudinal rolling passes n:3

[0048] Maximum depression: 40mm

[0049] Rolling procedure: direct longitudinal rolling without forming and widening passes

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com