Method for producing natural seasoning with antihypertensive effect by processing byproduct using agaricus bisporus

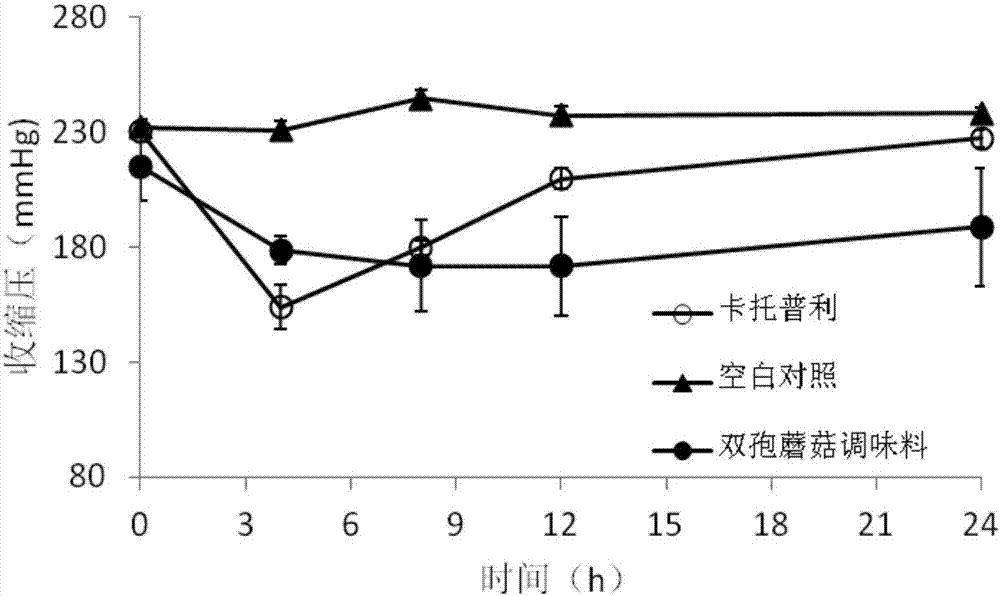

A technology of Agaricus bisporus and by-products, which is applied in the field of natural seasonings, can solve the problems of reducing the heavy metal content of the pre-cooking liquid of Agaricus bisporus, the hypotensive effect of mushroom seasoning powder is not ideal, and the anti-caking treatment is not carried out, and the promotion value is high. , The effect of removing special fishy smell and not easy to absorb moisture and agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Production of condiments with antihypertensive effect by processing by-products of Agaricus bisporus

[0043] Collect 30L of by-product cooking soup produced during the production and processing of Agaricus bisporus as raw material, follow the steps below:

[0044] Concentration: The soup produced by cooking Agaricus bisporus is concentrated by a decompression heating concentrator to obtain a concentrated liquid. The vacuum degree of the decompression heating concentrator is kept at -0.1~0.09 Mpa, and the working temperature is 60~80°C. The solid content is 150g / L;

[0045] Ultrafiltration membrane fractionation: pump the concentrate into the roll-type ultrafiltration membrane equipment, the molecular weight cut-off of the roll-type ultrafiltration membrane used is 1500Da, the ultrafiltration process conditions are: room temperature to 40 ℃, inlet pressure 3-4 bar, outlet pressure Press 2 to 3 bar, then collect the filtrate;

[0046] Column passing: Flow th...

Embodiment 2

[0051] Example 2: Production of condiments with antihypertensive effect by processing by-products of Agaricus bisporus

[0052] Collect 20L of by-product cooking soup produced during the production and processing of Agaricus bisporus, and use it as a raw material, follow the steps below:

[0053] Concentration: The soup produced by cooking Agaricus bisporus is concentrated by a decompression heating concentrator to obtain a concentrated liquid. The vacuum degree of the decompression heating concentrator is kept at -0.1~0.09 Mpa, and the working temperature is 60~80°C. The solid content is 125g / L;

[0054] Ultrafiltration membrane fractionation: pump the concentrate into the roll-type ultrafiltration membrane equipment, the molecular weight cut-off of the roll-type ultrafiltration membrane used is 1500Da, the ultrafiltration process conditions are: room temperature to 40 ℃, inlet pressure 3-4 bar, outlet pressure Press 2 to 3 bar, then collect the filtrate;

[0055] Column pa...

Embodiment 3

[0060] Example 3: Production of condiments with antihypertensive effect by processing by-products of Agaricus bisporus

[0061] Collect 18L of by-product cooking soup produced during the production and processing of Agaricus bisporus, and use it as a raw material, follow the steps below:

[0062] Concentration: The soup produced by cooking Agaricus bisporus is concentrated by a decompression heating concentrator to obtain a concentrated liquid. The vacuum degree of the decompression heating concentrator is kept at -0.1~0.09 Mpa, and the working temperature is 60~80°C. The solid content is 100g / L;

[0063] Ultrafiltration membrane fractionation: pump the concentrate into the roll-type ultrafiltration membrane equipment, the molecular weight cut-off of the roll-type ultrafiltration membrane used is 1500Da, the ultrafiltration process conditions are: room temperature to 40 ℃, inlet pressure 3-4 bar, outlet pressure Press 2 to 3 bar, then collect the filtrate;

[0064] Column pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com