Mutton sheep pellet feed and preparation method thereof

A technology of pellet feed and mutton sheep, which is applied in the field of pellet feed for mutton sheep and its preparation, can solve problems such as lack of roughage, achieve the effects of improving meat quality, avoiding environmental pollution, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Use 20kg of corn, 7.5kg of soybean meal, 2kg of cotton meal, 61kg of corn stalks, 3kg of sunflower shells and 3kg of peanut shells as the first raw material; Sodium and 0.2kg sodium humate are used as the second raw material; 0.8kg compound premix is used as the third raw material, wherein the compound premix contains 640000IU vitamin A and 240000IU vitamin D 3 , 2000IU vitamin E, 1600mg niacin, 12mg biotin, 1.6g copper, 4.9g iron, 3.6g manganese, 4.5g zinc, 64mg iodine, 16mg selenium and 25mg cobalt.

[0028] Mix the above-mentioned first raw material, second raw material and third raw material in a mixer for 100s to obtain a mixed material, and then mix the mixed material under the conditions of 70°C, ring membrane aperture of 4.5mm and ring die compression ratio of 1:5 Pellet to obtain a mutton sheep pellet feed with a length of 8 mm.

Embodiment 2

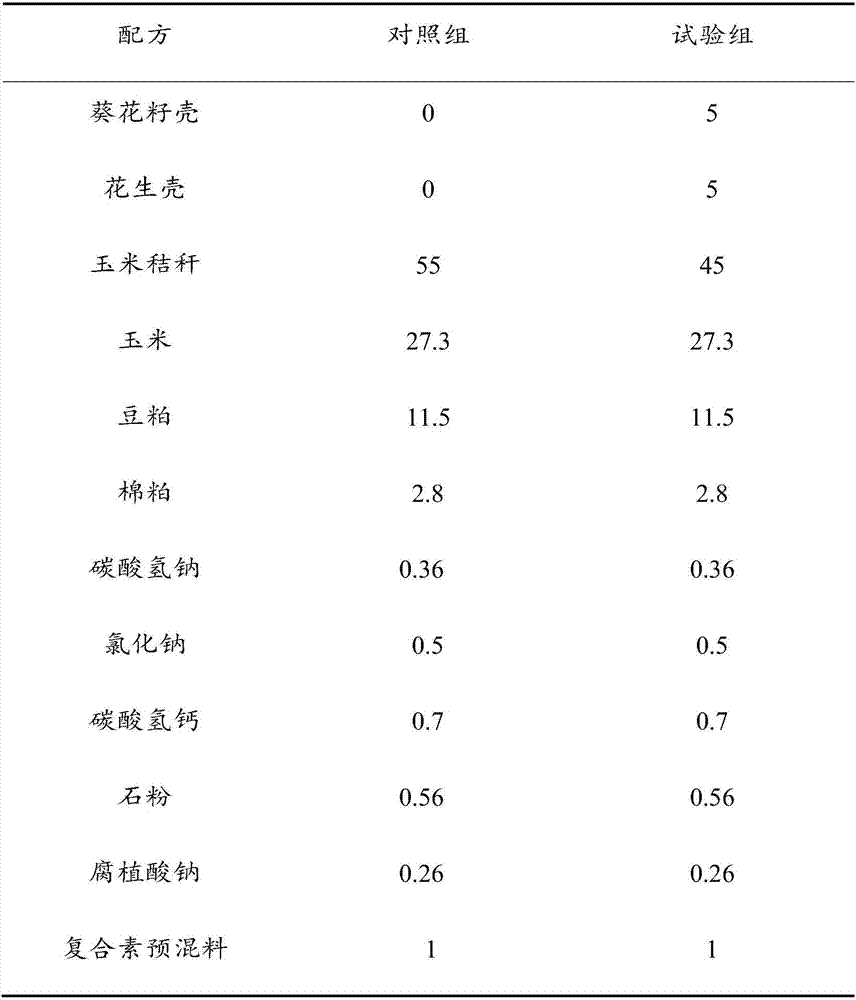

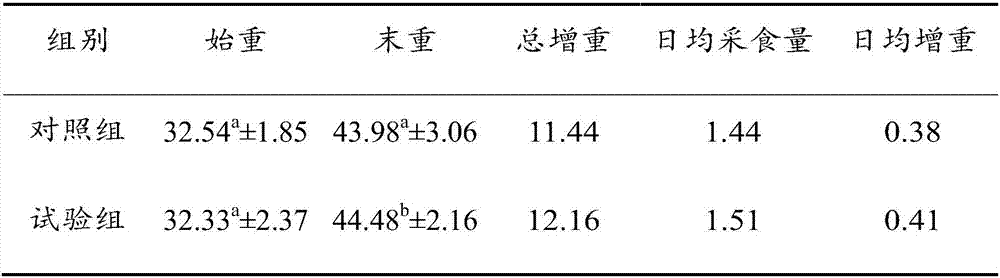

[0030] 27.3kg of corn, 11.5kg of soybean meal, 2.8kg of cotton meal, 45kg of corn stalks, 5kg of sunflower shells and 5kg of peanut shells are used as the first raw material; 0.7kg of calcium hydrogen phosphate, 0.56kg of stone powder, 0.5kg of sodium chloride, 0.36kg of Sodium bicarbonate and 0.26kg sodium humate are used as the second raw material; 0.9kg compound premix is used as the third raw material, wherein the compound premix contains 800000IU vitamin A and 300000IU vitamin D 3 , 2500IU vitamin E, 2000mg niacin, 15mg biotin, 2g copper, 6.1g iron, 4.5g manganese, 5.5g zinc, 80mg iodine, 20mg selenium and 25mg cobalt.

[0031] Crush the above-mentioned corn, soybean meal and cotton meal and pass through a sieve with a particle size of 2 mm, crush the sunflower seed shell and peanut shell into 1.2 cm fragments, pre-mix the above-mentioned third raw material, and then put the crushed first raw material 1. The pre-mixed third raw material and the second raw material are m...

Embodiment 3

[0033] 25.4kg of corn, 10kg of soybean meal, 2.5kg of cotton meal, 51kg of corn stalks, 4kg of sunflower seed shells and 4kg of peanut shells are used as the first raw materials; 0.65kg of calcium hydrogen phosphate, 0.53kg of stone powder, 0.45kg of sodium Sodium hydrogen and 0.24kg sodium humate are used as the second raw material; 1.0kg compound premix is used as the third raw material, wherein the compound premix contains 720000IU vitamin A and 270000IU vitamin D 3 , 2250IU vitamin E, 1800mg niacin, 13.5mg biotin, 1.8g copper, 5.5g iron, 4.1g manganese, 5.0g zinc, 72mg iodine, 18mg selenium, 22.5mg cobalt.

[0034] Pulverize the above-mentioned corn, soybean meal and cotton meal and pass through a sieve with a particle size of 2 mm, crush the sunflower seed shell and peanut shell into 1 cm fragments, pre-mix the above-mentioned third raw material, and then mix the crushed first raw material, The pre-mixed third raw material and the second raw material are mixed in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com