Precise seeding mechanism of rice seeding machine

A precision seeding and seeding machine technology, which is applied to seeding machine parts, sowing seeders, etc., can solve problems such as cost increase, development and area expansion, and affecting the stability and increase of total rice production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

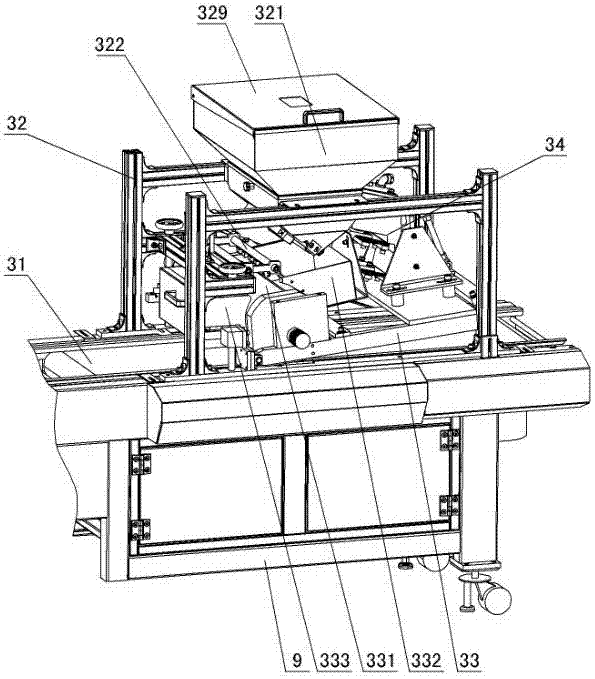

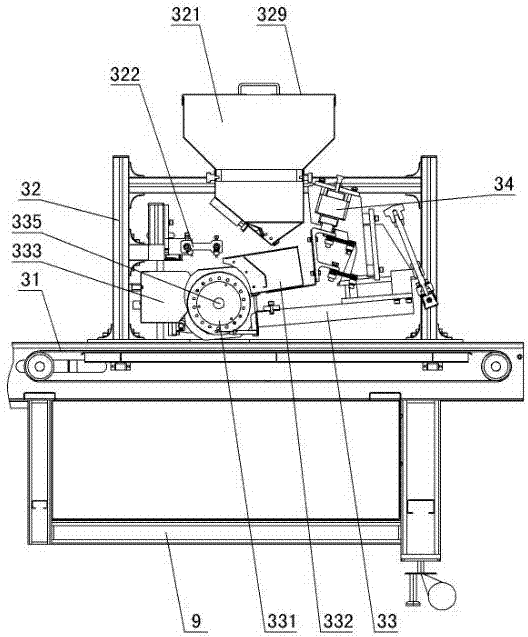

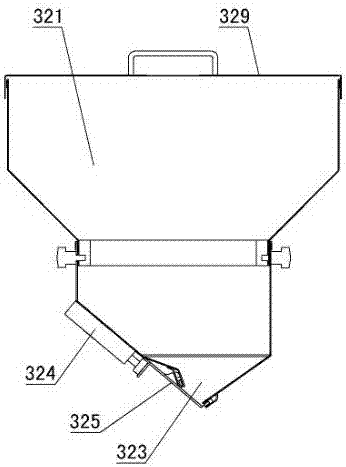

[0015] The present invention relates to a rice planter precision sowing mechanism, such as figure 1 — Figure 7 Shown, it is characterized in that: comprise frame 9, be provided with sowing conveyer belt 31 in the frame, sow conveyer belt moves through power drive, set sowing support 32 and inclined support 33 on the frame, set storage hopper 321 and 32 on the sowing support The blowing device 322, the outer wall of the storage hopper is provided with an automatic feeding control device, the automatic feeding control device includes a blanking opening 323 at the bottom of the storage hopper 321, and a material blocking cylinder 324 and a material blocking plate 325 are arranged on the front side of the storage hopper. The piston rod of the material cylinder is connected with the material retaining plate, and the material retaining plate is in contact with the blanking port 323. The air blowing device 322 includes an air blowing support 326, which is fixed with the seeding supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com