Plasma jet device

A plasma and jet device technology, applied in the field of plasma jet devices, can solve the problems of uneven plasma, uneven dry etching on the surface of the substrate, etc., and achieve the effects of high plasma particle activity and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

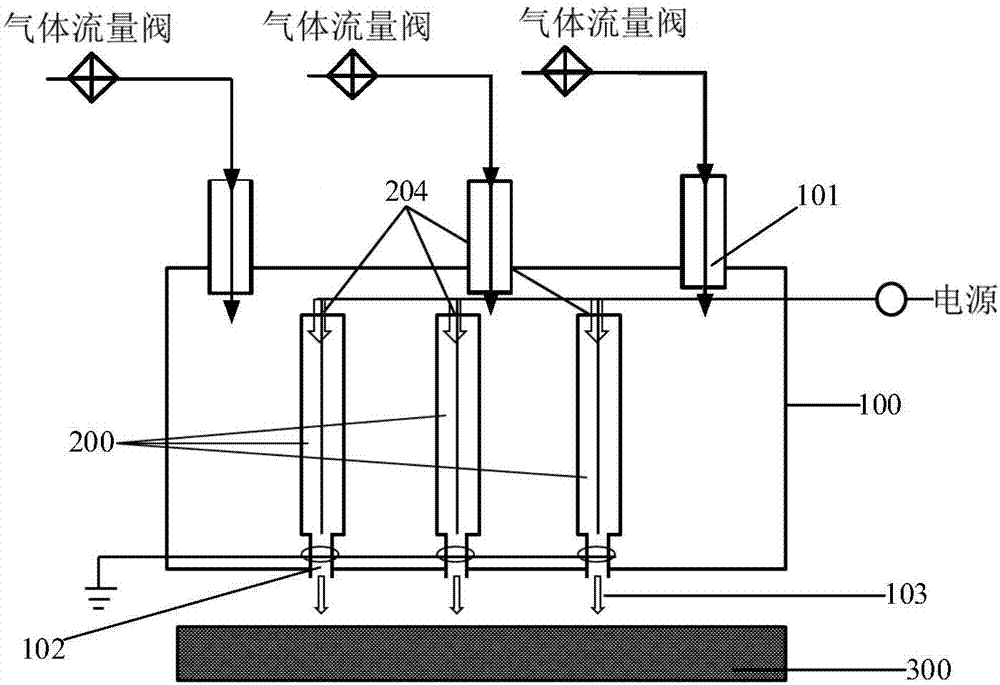

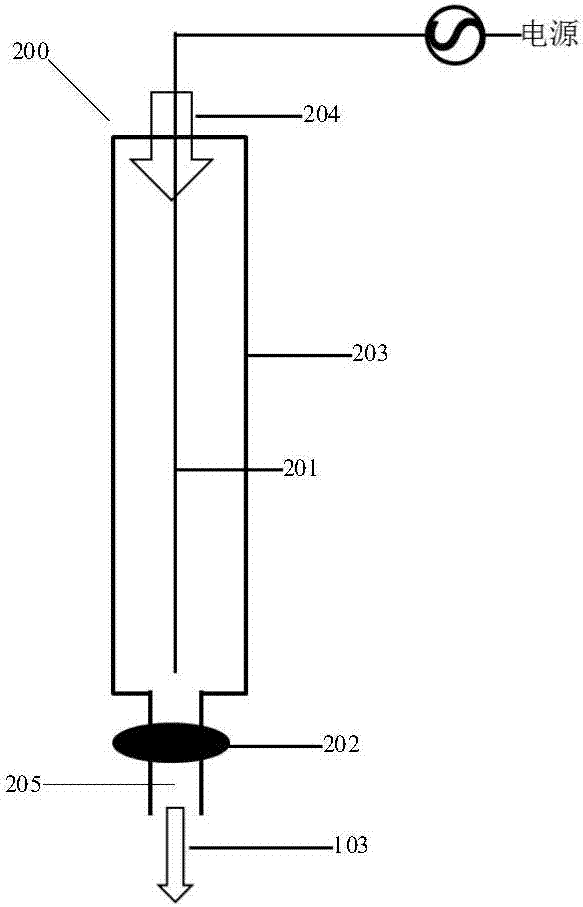

[0027] figure 1 It is a schematic structural diagram of a plasma jet device provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the plasma jet device includes a housing 100 surrounding and forming a discharge space. The housing 100 is provided with a first inlet 101 and a first outlet 102 , and a plurality of discharge units 200 are distributed in the housing 100 . The first inlet 101 is used to supply the reactive gas to the discharge unit 200, the discharge unit 200 is used to discharge the reactive gas to form a plasma jet 103, and the first outlet 102 is used to output The plasma jet 103 . The plasma formed by the plasma jet device provided in this embodiment forms large-area uniform and stable plasma jets 103 through the action of air flow, and these arrayed plasma jets 103 directly act on the substrate 300 to etch the thin film transistor, and finally A thin film transistor plasma etching process that separates the discharge area from the wo...

Embodiment 2

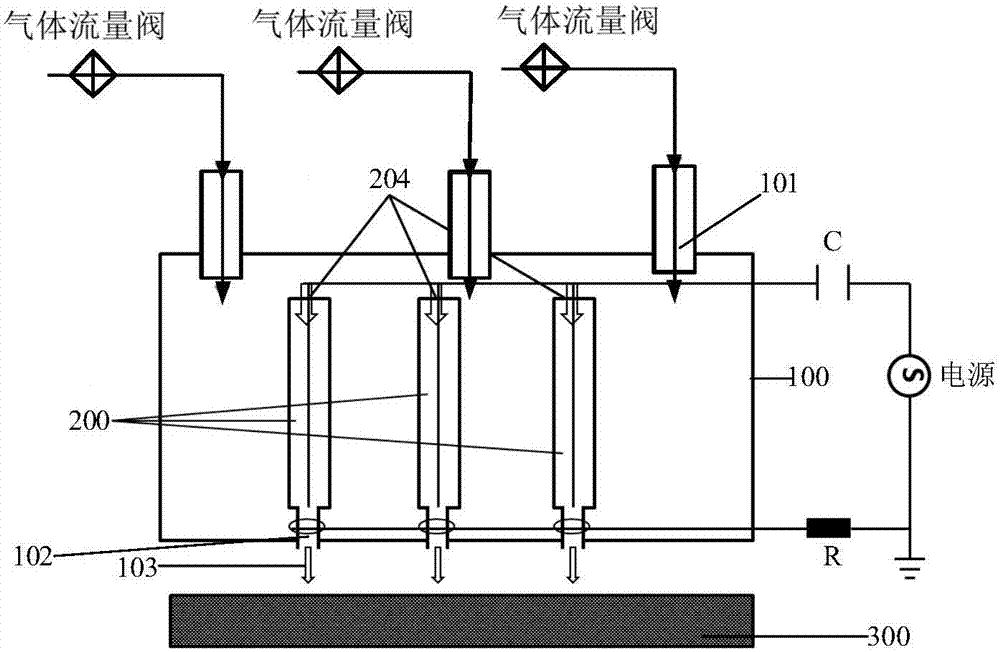

[0033] image 3 It is a schematic structural diagram of a plasma jet device provided in Embodiment 2 of the present invention. Such as image 3 As shown, the plasma jet device includes a housing 100 on which a first inlet 101 and a first outlet 102 are disposed, and a plurality of discharge units 200 are distributed in the housing 100 . The first inlet 101 is used to supply the reactive gas to the discharge unit 200, the discharge unit 200 is used to discharge the reactive gas to form a plasma jet 103, and the first outlet 102 is used to output The plasma jet 103 . The plasma formed by the plasma jet device provided in this embodiment forms large-area uniform and stable plasma jets 103 through the action of air flow, and these arrayed plasma jets 103 directly act on the substrate 300 to etch the thin film transistor, and finally A thin film transistor plasma etching process that separates the discharge area from the work area. The technical solution provided in this embodi...

Embodiment 3

[0040] Figure 5 It is a schematic structural diagram of a plasma jet device provided in Embodiment 3 of the present invention. It should be noted that the difference between the plasma jet device provided in this embodiment and the plasma jet device provided in Embodiment 1 lies in the arrangement of the discharge cells 200, therefore Figure 5 Mainly shows the arrangement of the discharge unit 200, for other parts of the plasma jet device, please refer to figure 1 . see figure 1 with Figure 5 , the plasma jet device includes a casing 100, on which a first inlet 101 and a first outlet 102 are arranged, and a plurality of discharge units 200 are distributed in the casing 100. The first inlet 101 is used to supply the reactive gas to the discharge unit 200, the discharge unit 200 is used to discharge the reactive gas to form a plasma jet 103, and the first outlet 102 is used to output The plasma jet 103 . The plasma formed by the plasma jet device provided in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com