High-tenacity terminal board used for transformer and mutual inductor

A terminal block and transformer technology, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve the hidden dangers of transformer and transformer normal operation, transformer oil leakage, terminal Plate cracks and other problems, to avoid oil leakage, improve impact strength, and eliminate hidden dangers of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

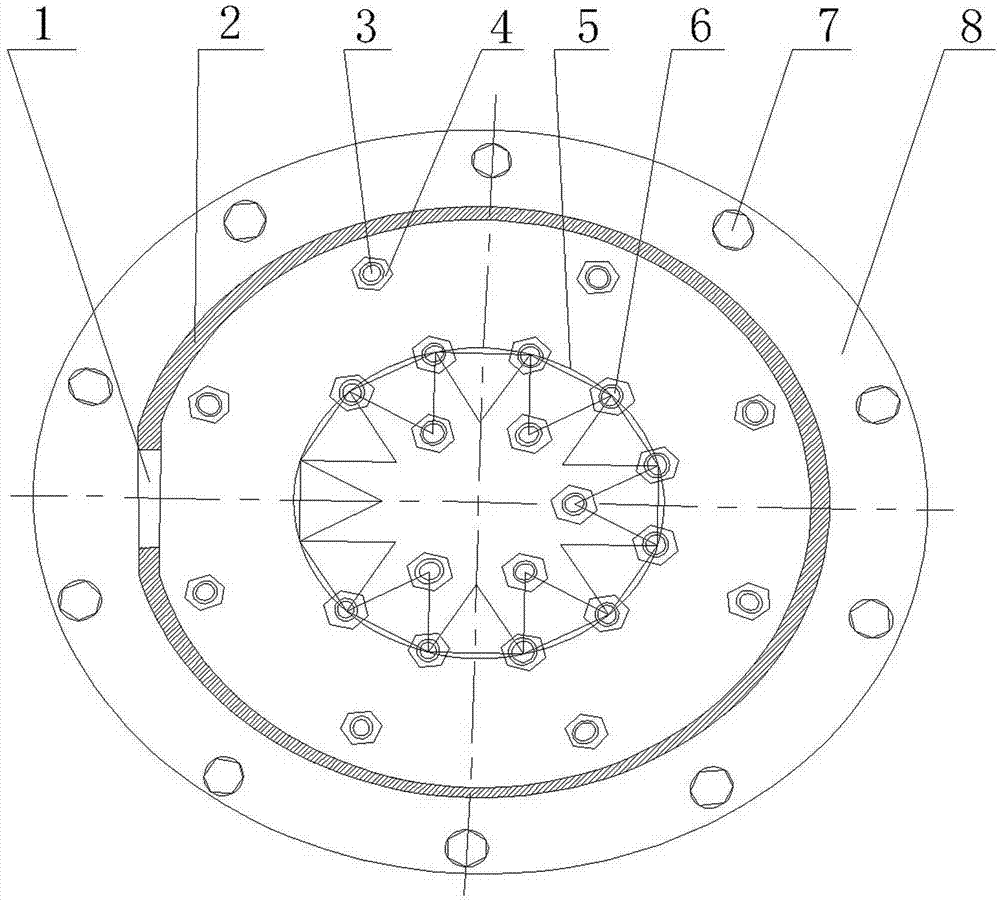

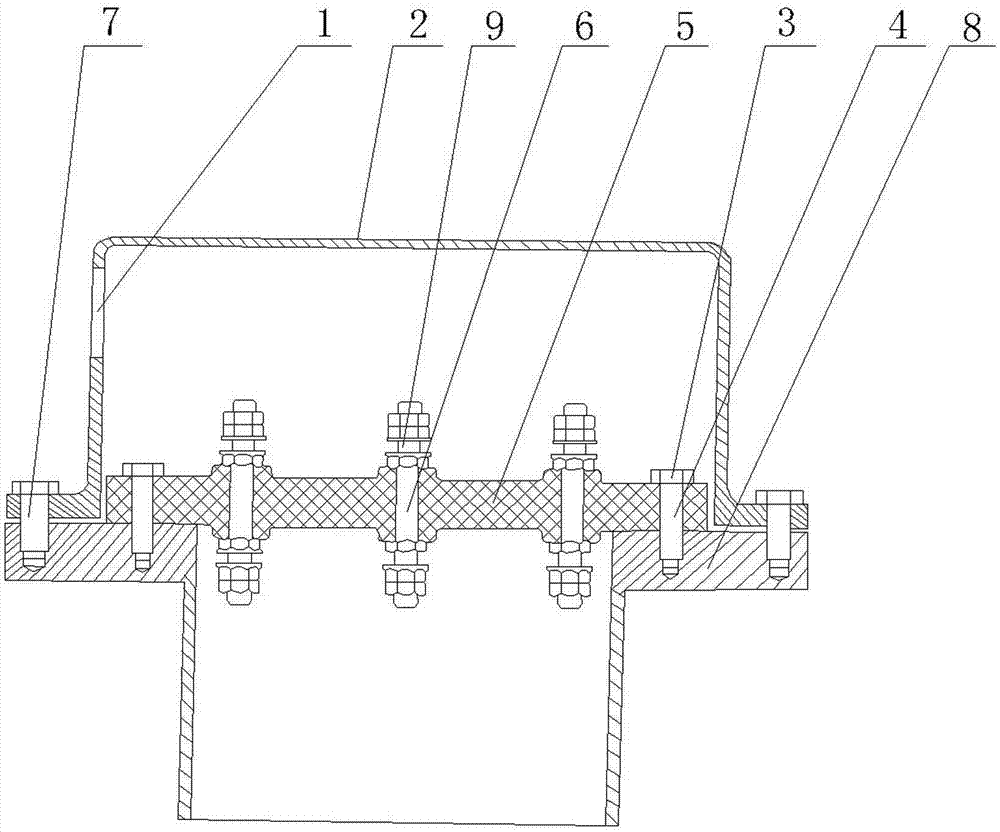

[0022] combined with figure 1 and 2 As shown, the high-toughness terminal board for transformers and transformers of the present invention includes a riser 8 for transformers and transformers, a housing 2 arranged on the top of the riser 8, and an external mounting bolt 7 is installed between the housing 2 and the riser 8. It is fixedly connected; the main points of its structure are: the upper part of the raised seat 8 and the inside of the housing 2 are provided with a terminal board 5; Mounting holes 4 are evenly distributed around the plate 5, and internal mounting bolts 3 are provided through the mounting holes 4, and are fixedly connected to the rising seat 8 through the internal mounting bolts 3; the shell 2 is provided with a shell opening 1; the terminal Connecting terminals 6 are evenly arranged and distributed on the board 5 , and the upper and lower ends of the connecting terminals 6 are connecting terminals 9 .

[0023] The terminal plate 5 has a disc-shaped str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com